Segmented combined type concrete telegraph pole and pipe manufacturing forming mechanism thereof

A technology of segmental combination and forming mechanism, applied in the field of utility poles, can solve the problems of cracking of the pole body, deep anchoring of the utility pole, freezing of water and liquid, etc., to improve the stability, prevent the temperature difference from changing too fast, and delay the temperature change. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

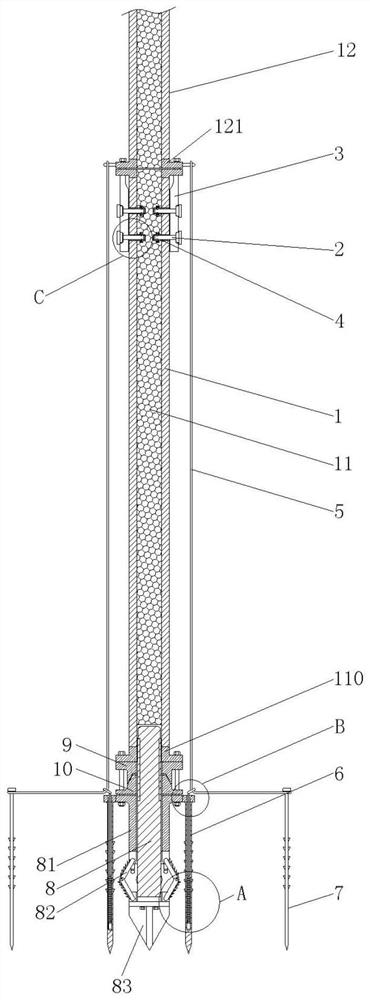

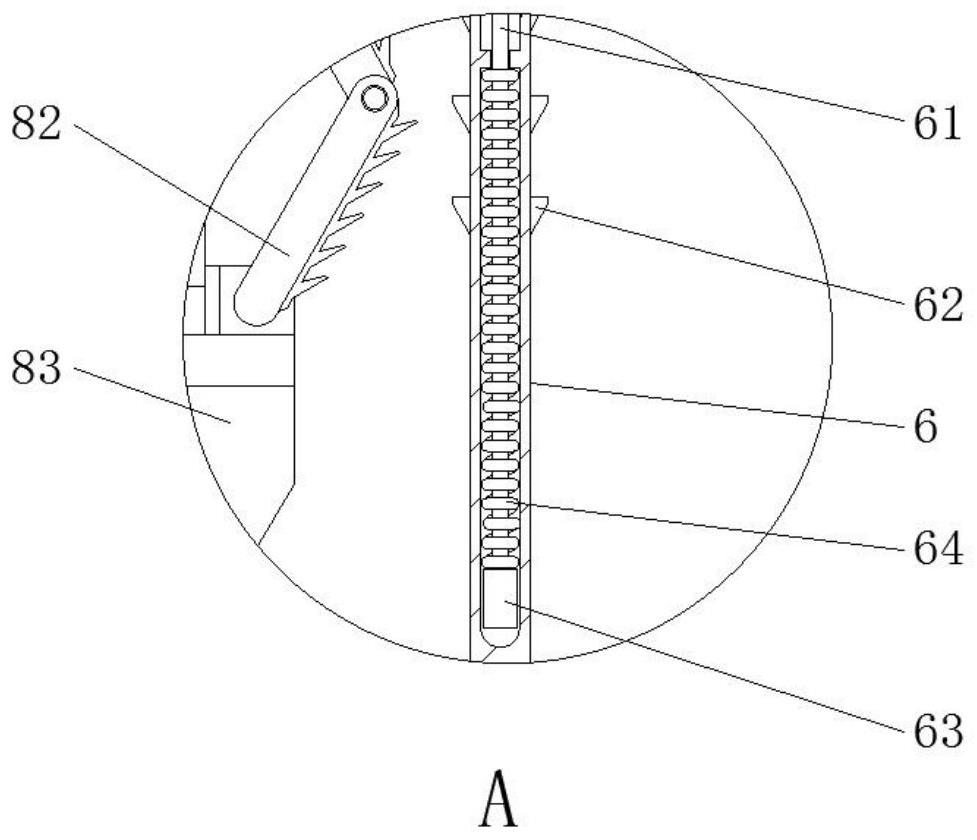

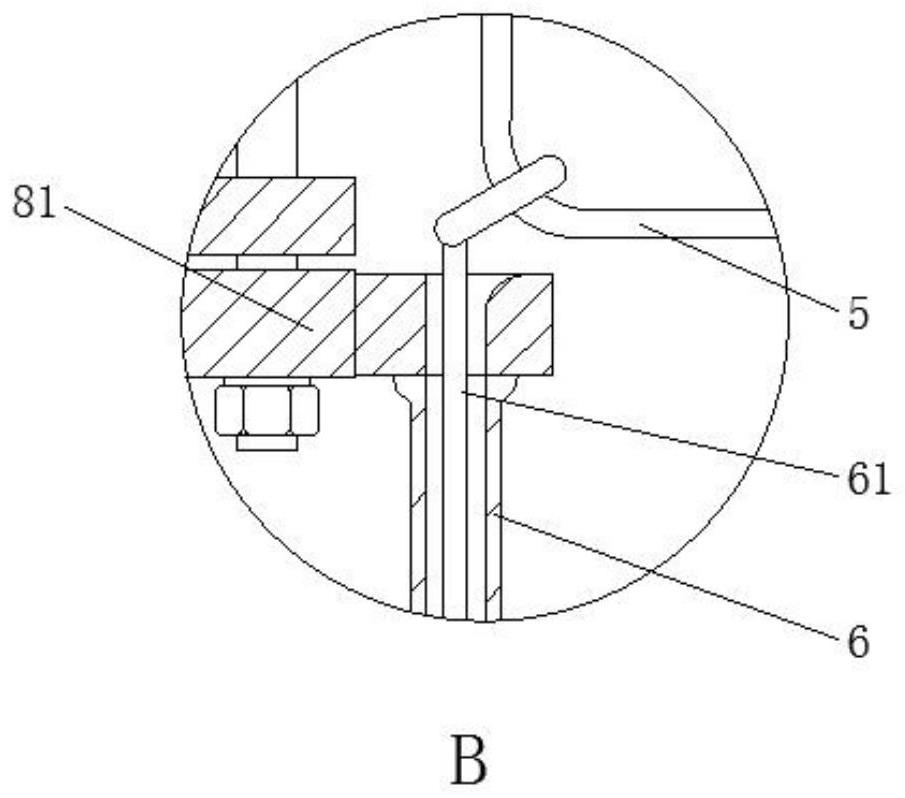

[0061] like Figure 1-Figure 18 As shown, a segmented combined concrete utility pole is characterized in that: it includes a middle section combined pole 1, the lower end of the middle section combined pole 1 is assembled and connected with a base pole 8, the lower end of the base pole 8 is provided with a tip 83, and the base pole 8. A sleeve 81 is provided on the outside of the sleeve 81. Between the sleeve 81 and the rod tip 83, there is a mutually hinged expansion anchor bar 82. The upper end of the middle composite rod 1 is assembled and connected with an upper composite rod 12. One side of the upper composite rod 12 is connected with a The stay rope 5 is connected to the base pole 8 through the buffer anchor 6, and the lower end of the stay rope 5 extends laterally away from the base pole 8, and the lower end of the stay rope 5 is connected with a positioning anchor 7.

[0062] Through the assembly structure of the base pole 8 and the middle section of the combined pole ...

Embodiment 2

[0080] like figure 1 , figure 2 , Figure 5 , Image 6 and Figure 9-Figure 11 As shown, a segmented combined concrete utility pole is characterized in that: it includes a middle section combined pole 1, the lower end of the middle section combined pole 1 is assembled and connected with a base pole 8, the lower end of the base pole 8 is provided with a tip 83, and the base pole 8. A sleeve 81 is provided on the outside of the sleeve 81. Between the sleeve 81 and the rod tip 83, there is a mutually hinged expansion anchor bar 82. The upper end of the middle composite rod 1 is assembled and connected with an upper composite rod 12. One side of the upper composite rod 12 is connected with a The stay rope 5 is connected to the base pole 8 through the buffer anchor 6, and the lower end of the stay rope 5 extends laterally away from the base pole 8, and the lower end of the stay rope 5 is connected with a positioning anchor 7.

[0081] There are several groups of expansion anch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com