Full-automatic electronic lock body

An electronic lock, fully automatic technology, applied to non-mechanical transmission-operated locks, building locks, buildings, etc., to achieve the effect of improving work efficiency and facilitating recycling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

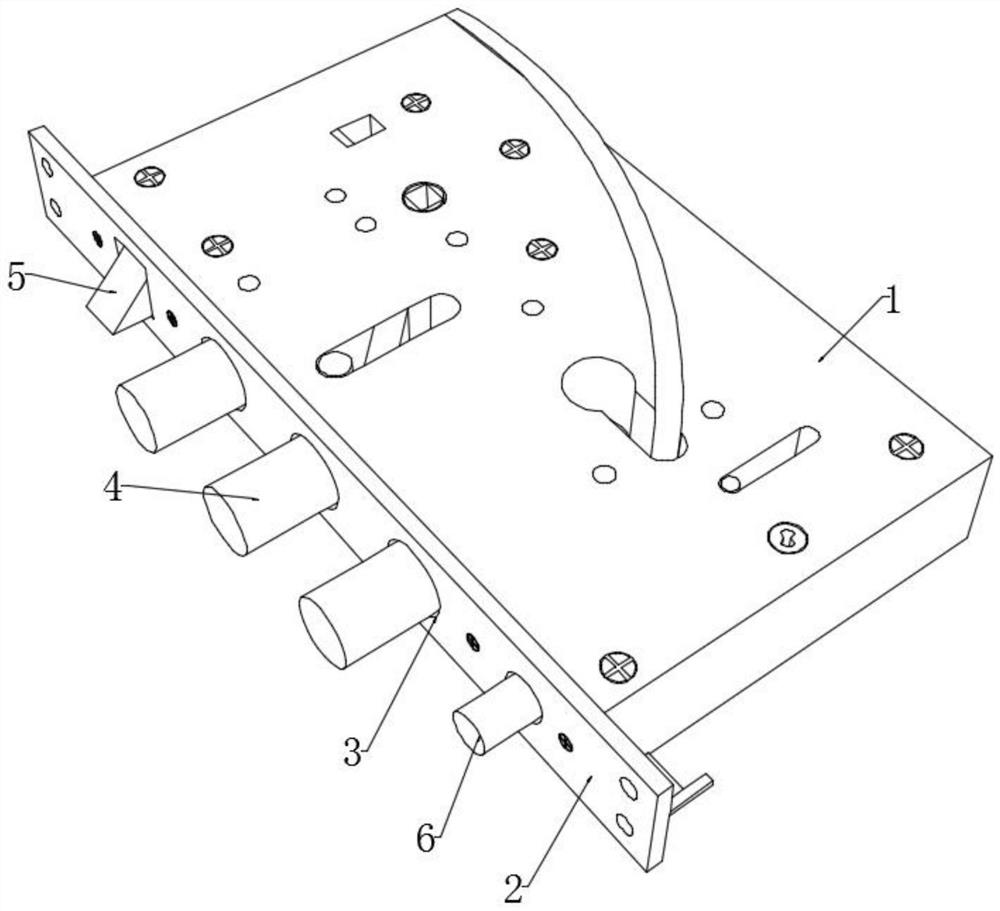

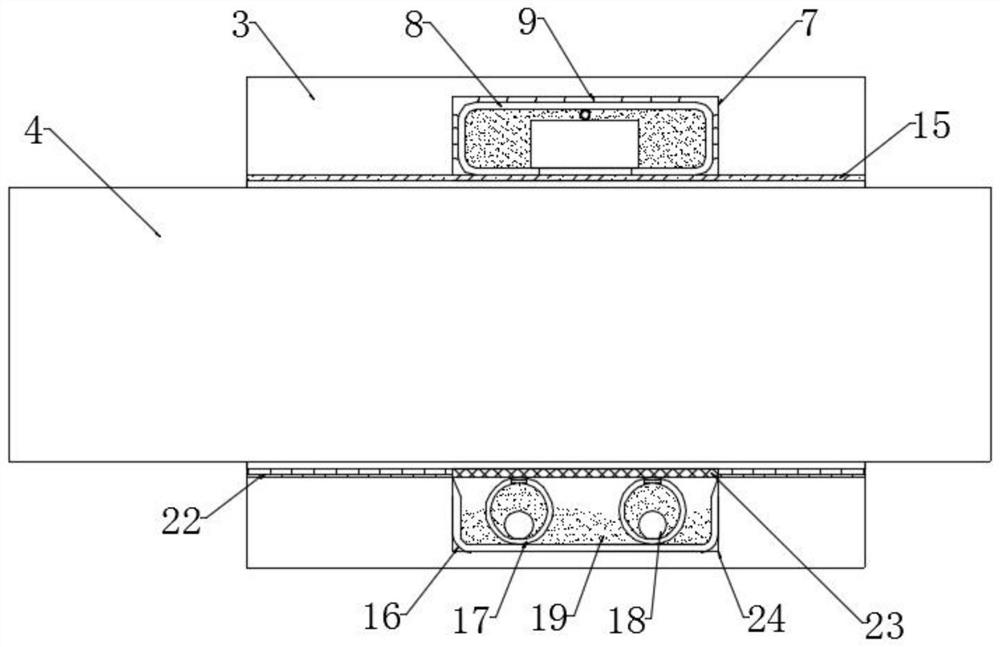

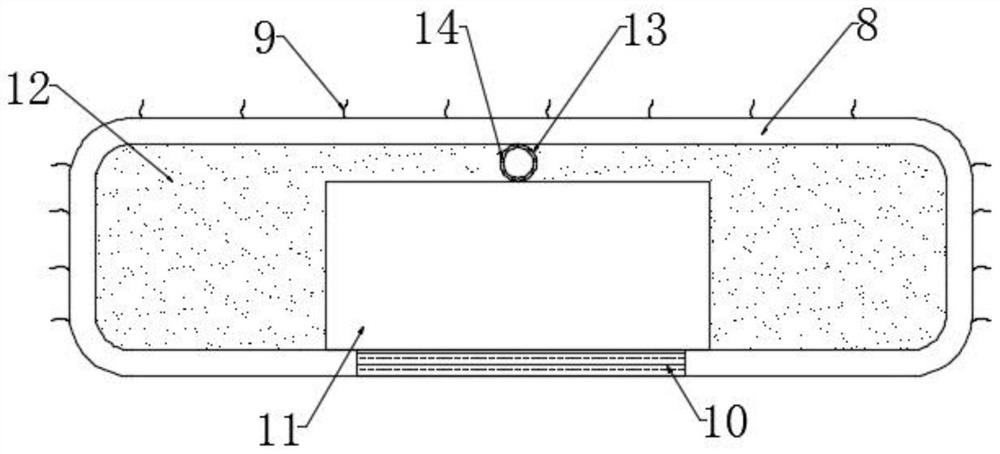

[0041] see Figure 1-5 , a fully automatic electronic lock body, including an electronic lock block 1, the outer end of the electronic lock block 1 is fixedly connected with a guide plate 2, and the outer end of the guide plate 2 is dug with a plurality of evenly distributed tongue grooves 3, and the tongue groove 3 is slidingly connected with a main The tongue 4 is slidingly connected with the oblique tongue 5 inside the guide plate 2, and the safety tongue 6 is slidably connected with the inside of the guide plate 2. The groove 7 and the second groove 24, the second groove 24 is provided with an adsorption device, the first groove 7 is provided with an expansion balloon 8, and the expansion balloon 8 is fixedly connected with the inner wall of the first groove 7 A plurality of evenly distributed heat-conducting fibers 9, a flow channel 10 is embedded at the lower end of the inflatable balloon 8, and a limit block 11 is provided at the inner bottom of the inflatable balloon 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com