Method for arranging and supporting roadways of upper and lower coal seams at extremely close distances

A very short-distance, roadway layout technology, applied in tunnels, earthwork drilling, underground mining, etc., can solve the problems of excessively large coal pillars, reduced coal recovery rate, waste of coal pillar resources, etc., and achieves small roadway deformation , Improve the utilization rate of coal resources and reduce the effect of roadway deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the present invention, the technical solutions of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention, rather than limiting the claims of the present invention.

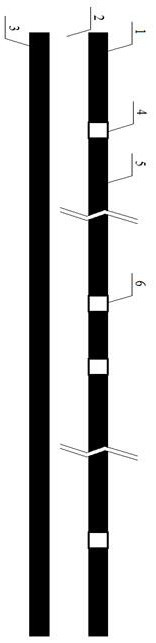

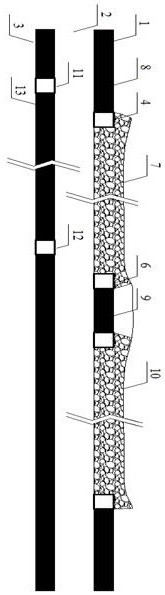

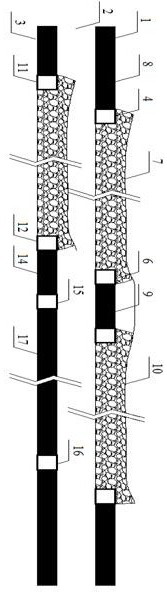

[0028] The following is a detailed description based on the contents of the accompanying drawings, please refer to the attached figure 1 , 2 , 3, 4, 5, 6.

[0029] There are two unexploited upper and lower coal seams in a mine, with a buried depth of 250m, an upper coal seam thickness of 2.8m, a lower coal seam thickness of 3m, and an interlayer spacing of 2.5m between the upper coal seam and the lower coal seam.

[0030] The first step: the upper coal seam 1 is mined according to the 121 construction method, and a coal mining face, two recovery roadways, and one coal pillar are arranged. The remaining coal pillars 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com