Method and measuring device for measuring or calibrating utensils in pressing processes

A technology of measuring devices and tools, applied in measuring devices, manufacturing tools, presses, etc., can solve problems such as insecurity, achieve the effects of short time consumption, shortened setting time, and improved setting quality or accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

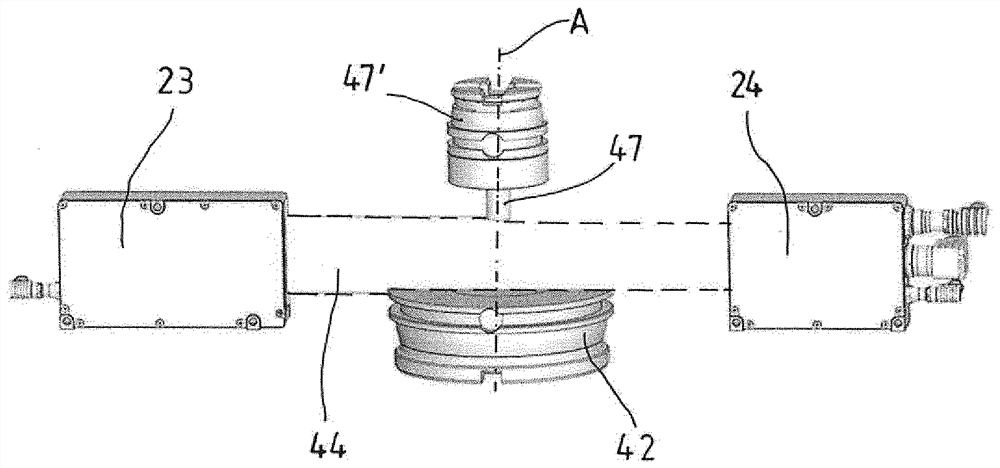

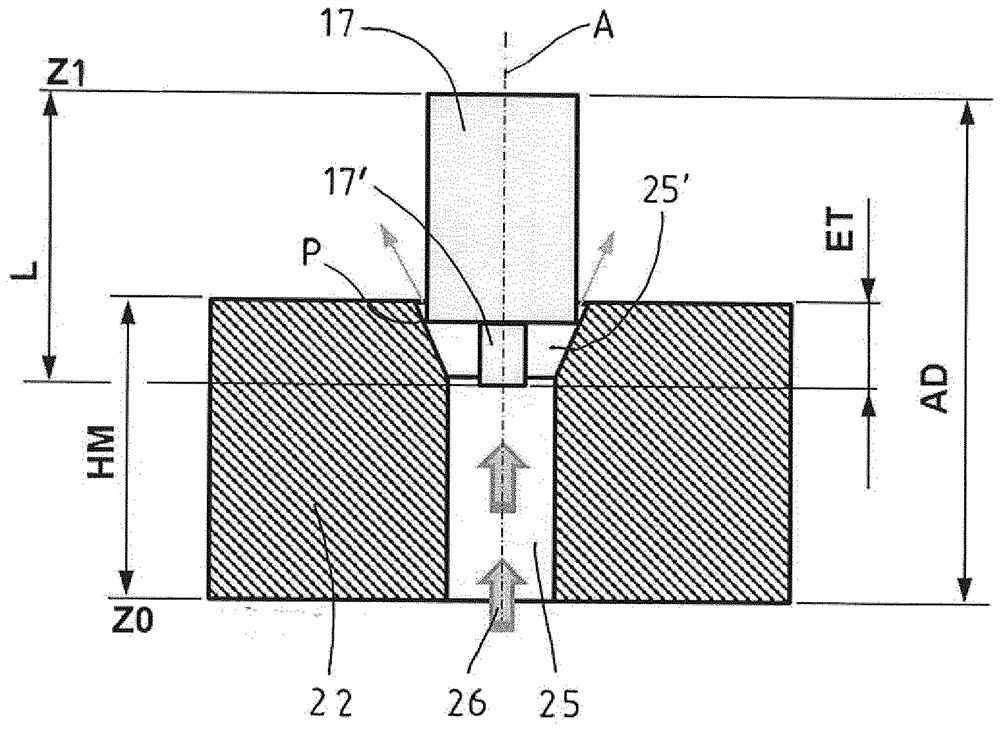

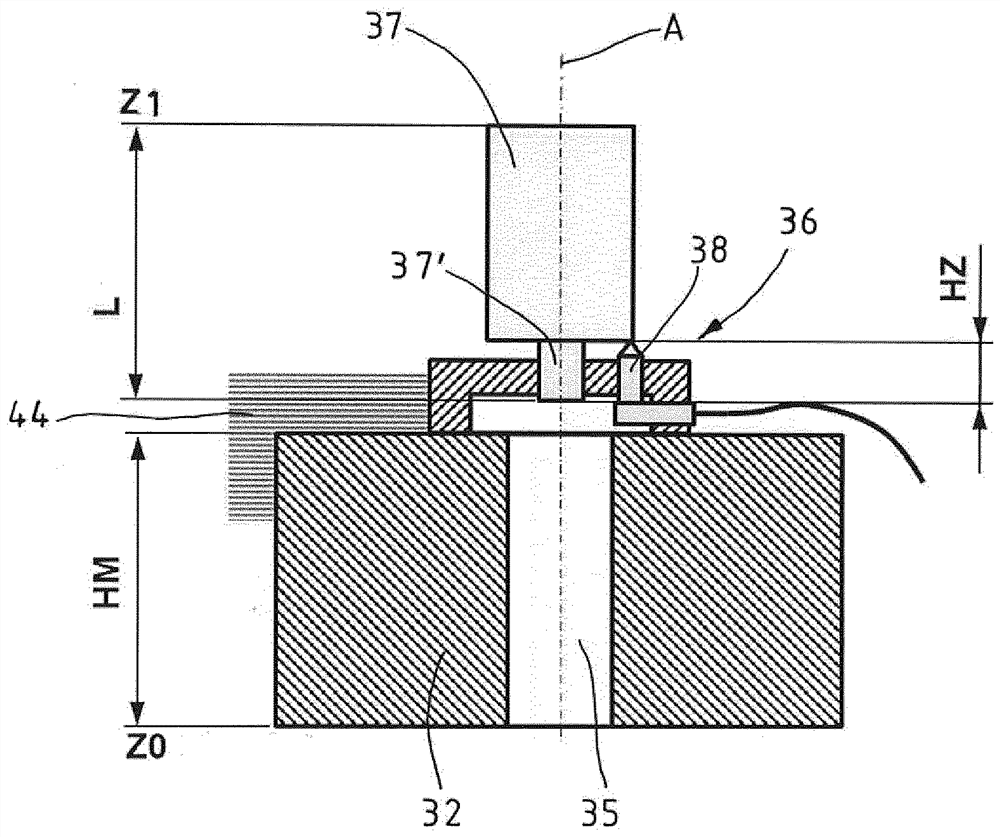

[0018] figure 1 Shown is a measuring device 10 with a vertically arranged stand 11 , lower and upper transverse receiving plates 12 , 13 secured thereto, and a height-adjustable measuring table between the receiving plates at the stand 11 20. On or below the corresponding receiving plate 12, 13 and on the measuring table 20 are respectively preferably fastened chucks 14, 15, 21 for positioning tools, wherein the chucks can be moved by different means depending on the tool to be used. Size designed chuck to replace.

[0019] Using this measuring device 10 , in particular during pressing, tools can be measured or calibrated, which relate to tools, dies 16 , 17 , die unit 22 and chucks 14 , 15 , 21 or the like. For various tools or for components in general mechanical engineering, such as for valves, engine parts, bushings or the like, compacts are produced from iron powder, hard metal powder or ceramic powder using pressing plants.

[0020] In the method according to the inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com