Raw material storage cabinet system applied to cooking machine

A storage system, raw material technology, applied in the field of raw material storage system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

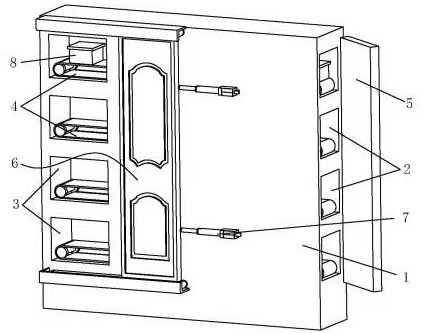

[0013] Step 1: Manually or automatically open the heat preservation door (5) at the entrance of the material box (2) at the front of the storage cabinet, use manual or automatic devices to load the material box (8) and arrange it on the conveyor belt (4), and complete Finally close the insulation door (5).

[0014] Step 2: When the material box extraction device of the cooking machine wants to take away the material box (8) at the output port (3), the heat preservation door (6) at the output port (3) will automatically open, and after the extraction is completed, the output port ( 3) The thermal insulation door (5) closes automatically.

[0015] Step 3: After the material box (8) at the output port (3) is taken away, the conveyor belt (4) will transport the subsequent material box (8) stored on the conveyor belt to the position for use.

[0016] Compared with the prior art, the present invention has the advantages of: the freshness preservation function is fully realized duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com