Intelligent infusion monitor control method for accurately controlling dripping speed based on stepping motor

A stepping motor, precise control technology, applied in the direction of non-electric variable control, flow control, flow monitor, etc., can solve the problems of low adjustment accuracy, large error of gravity infusion pump, and can not be applied, so as to filter out environmental interference , Accurate speed measurement, rapid speed adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

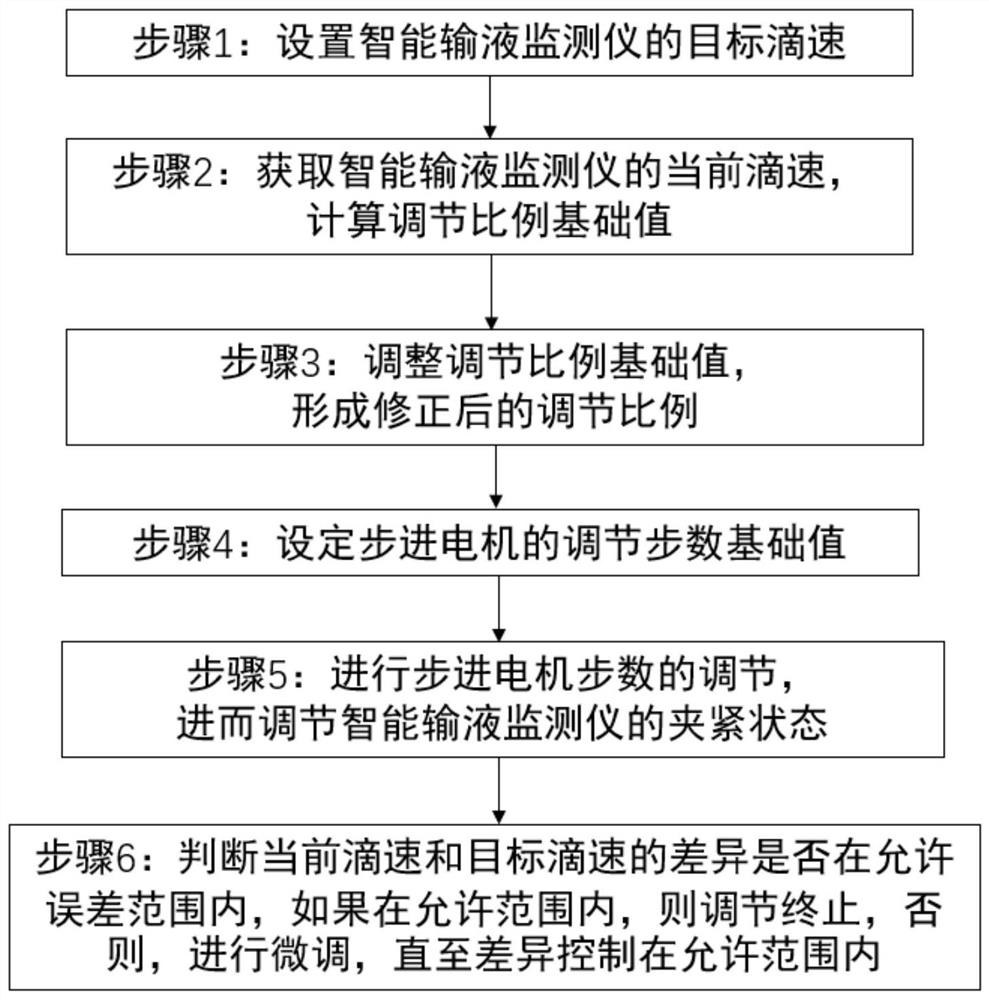

[0061] like figure 1 As shown, a control method of an intelligent infusion monitor based on a stepping motor to accurately control the drip speed includes the following steps:

[0062] Step 1: Set the target drip rate of the intelligent infusion monitor;

[0063] Step 2: Obtain the current drip rate of the intelligent infusion monitor, and calculate the basic value of the adjustment ratio based on the difference between the current drip rate of the intelligent infusion monitor and the target drip rate;

[0064] Step 3: Based on the target drip rate value of the intelligent infusion monitor, adjust the basic value of the adjustment ratio to form a revised adjustment ratio;

[0065] Step 4: Based on the current drip speed of the intelligent infusion monitor, set the basic value of the number of adjustment steps of the stepper motor;

[0066] Step 5: The stepper motor adjusts the number of steps of the stepper motor based on the basic value of the number of adjustment steps and...

Embodiment 2

[0091] The difference between embodiment 2 and embodiment 1 is only that: the current drip speed is calculated by weighting and removing extreme values, and the influence of extreme values and water droplet stickiness is deducted.

[0092] Concrete, preferably, the calculation of current drop rate in step 2 comprises the following steps:

[0093] Step 2.1: Weighted calculation of the weighted velocity of each drop,

[0094] S wi = ω i S i +ω i-1 S i-1 +…+ω i-a+1 S i-a+1 (1)

[0095] Among them, S wi Indicates the weighted velocity of the i-th drop, S i Indicates the drop speed of the i-th drop, which is closest to the current moment, ω i Indicates the weighted weight of the i-th drop, a is the number of weighted drop speeds, which is a constant, a≥3,

[0096] Weights satisfy the following conditions:

[0097] ω i +ω i-1 +…+ω i-a+1 = 1 (2)

[0098] ω i > ω i-1 >…>ω i-a+1

[0099] preferred, ω i =(a-1) / a.

[0100] Step 2.2: Remove extreme dripping speeds...

Embodiment 3

[0107] The difference between embodiment 3 and embodiment 1 is only that: the droplet is detected by the capacitive sensor, and the time between two drops is recorded, so that the current dripping speed can be obtained, based on the difference between the current speed and the target speed, the calculation Need to advance the distance, and then drive the stepper motor to push the slider to a precise position.

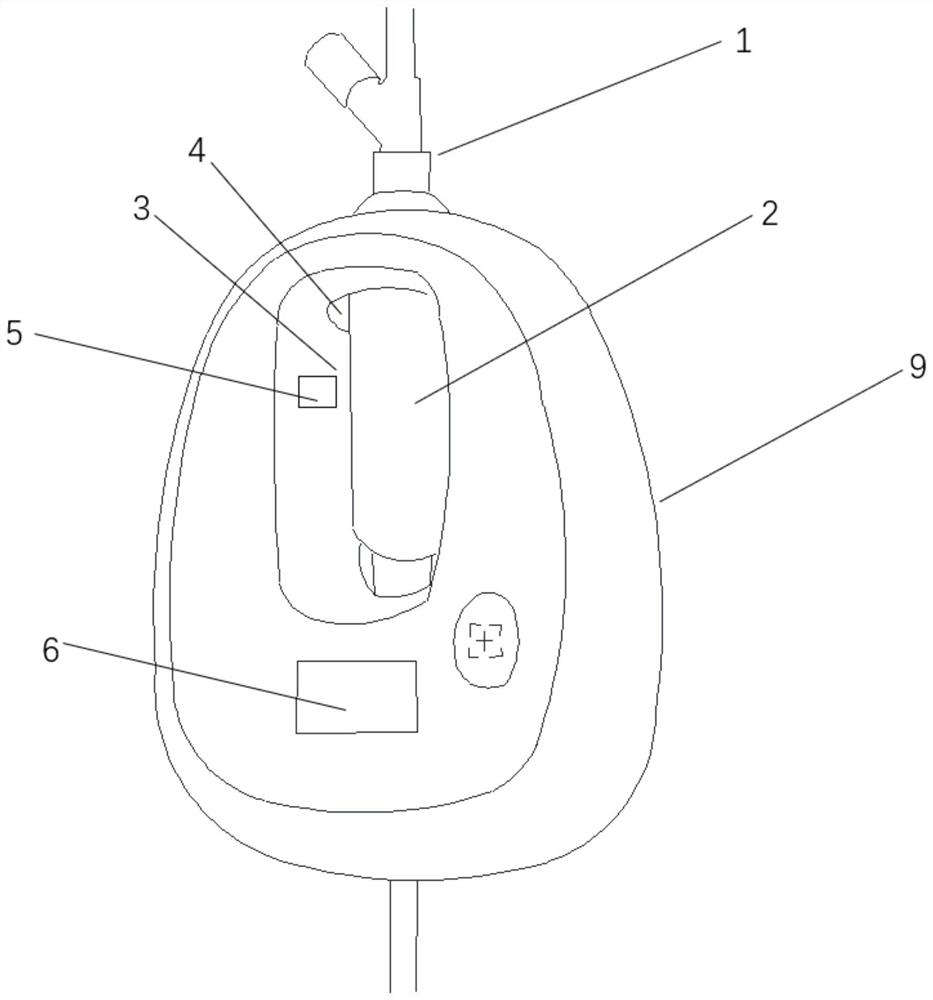

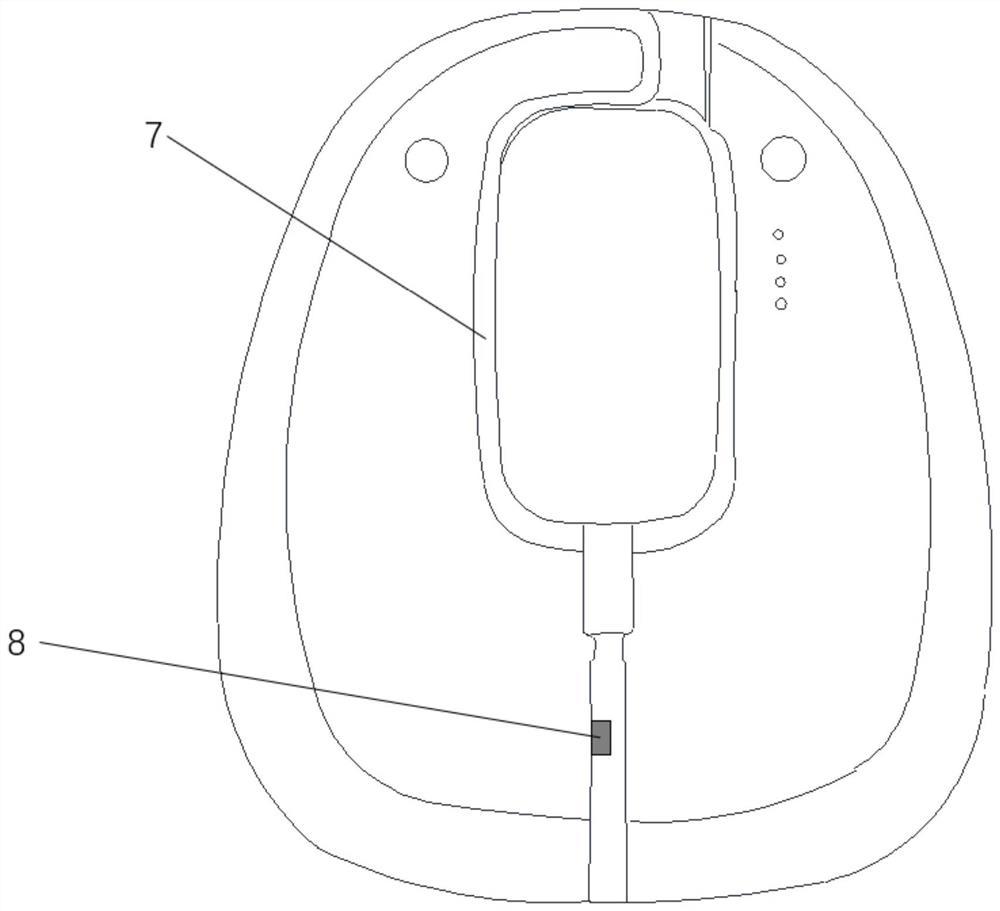

[0108] Specifically, the intelligent infusion monitor includes a monitor body 9, the front of the monitor body 9 is provided with a cavity 3 for accommodating the dripping funnel 2 of the infusion tube 1, and the monitor body 9 is located on the The top and bottom of the cavity 3 are respectively provided with holes 4 for the dripping funnel 2 to pass through freely. On the monitor body 9 and at the middle and upper position of the cavity 3, a capacitive sensor 5 is provided. The capacitive sensor 5. Record the real-time capacitance value in the horizontal direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com