Plate-and-frame type oil filter and control method thereof

An oil filter, plate-and-frame technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems affecting the normal use of plate-and-frame oil filters, affecting filtering effects, and filter cloth clogging, etc., to achieve The effect of increasing the running time, reducing oil leakage and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

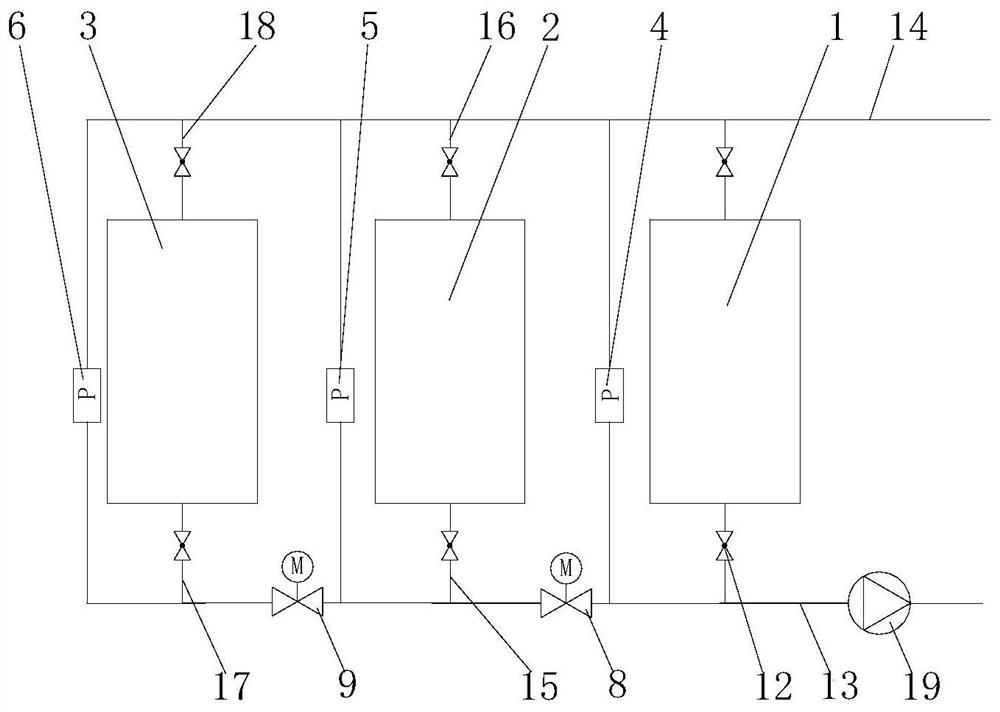

[0060] Such as figure 1 As shown, this embodiment provides a plate-and-frame oil filter unit, including a main filter plate module 1 and a spare filter plate module, the oil inlet end of the main filter plate module 1 and the main oil inlet pipe of the plate-and-frame oil filter unit 13, the oil outlet is connected to the main oil outlet pipeline 14, the oil flows into the main filter plate module 1 from the main oil inlet pipeline 13, and flows out from the main oil outlet pipeline 14 after being filtered by the main filter plate module 1, completing the oil filtration The spare filter plate module is connected between the main oil inlet pipeline 13 and the main oil outlet pipeline 14, and is arranged in parallel with the main filter plate module 1, when the main filter plate module 1 cannot be used normally, it is guaranteed that the oil can be fed by the main oil inlet The oil pipe 13 flows into the spare filter plate module. The spare filter plate module setting can effec...

Embodiment 2

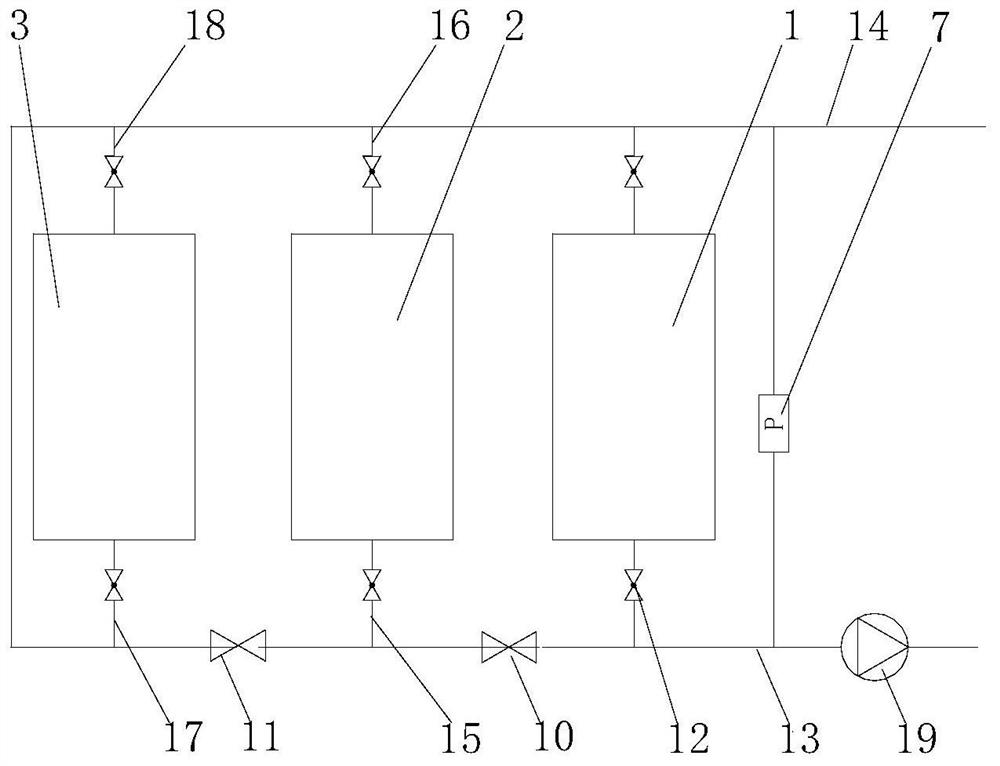

[0085] The difference between this embodiment and the first embodiment above is that the differential pressure sensing module includes a fourth differential pressure sensor 7 for detecting the differential pressure between the main oil inlet pipeline 13 and the main oil outlet pipeline 14, which can be more intuitive Reflect the overall operation of the plate and frame oil filter unit.

[0086] Such as figure 2 As shown, in this embodiment, the first backup control valve is the first differential pressure valve 10, and when the pressure differential across the main filter plate module 1 reaches the set differential pressure, the first differential pressure valve 10 will automatically open; the second backup control valve is the second differential pressure valve 11, and when the differential pressure of the first backup filter plate module 2 reaches the set differential pressure, the second differential pressure valve 11 is automatically opened. This method of automatically ...

Embodiment 3

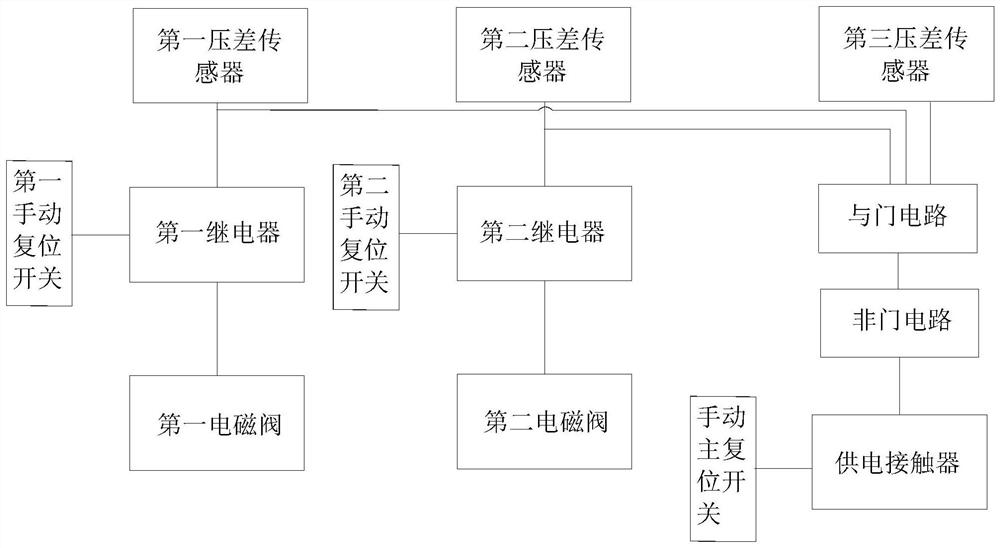

[0094] Such as Figure 5 , Figure 6 As shown, this embodiment provides a control method for the plate-and-frame oil filter unit in the above-mentioned embodiments, and controls switching of the main filter plate module 1 and / or Or the working status of the spare filter plate module.

[0095] Such as Figure 5 As shown, when the plate and frame oil filter is running, the first differential pressure sensor 4 detects the differential pressure at both ends of the main filter plate module 1 in real time. When the main filter plate module 1 works normally, the pressure detected by the first differential pressure sensor 4 The difference is small. After running for a period of time, the filter paper of the main filter plate module 1 will be clogged, and the pressure difference between the two ends of the main filter plate module 1 will gradually increase. When it is judged that the pressure detected by the first differential pressure sensor 4 When the pressure difference is greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com