Automatic battery masking tape pasting equipment

A technology of masking glue and batteries, which is applied in the direction of secondary battery manufacturing, conveyor objects, sustainable manufacturing/processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing:

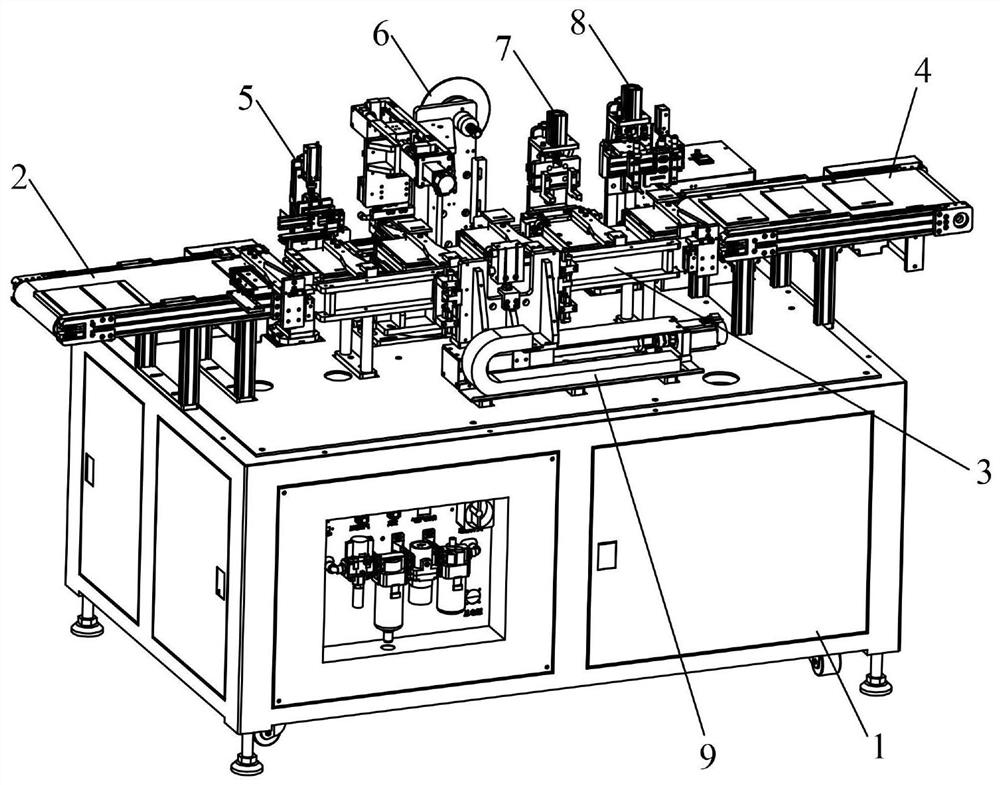

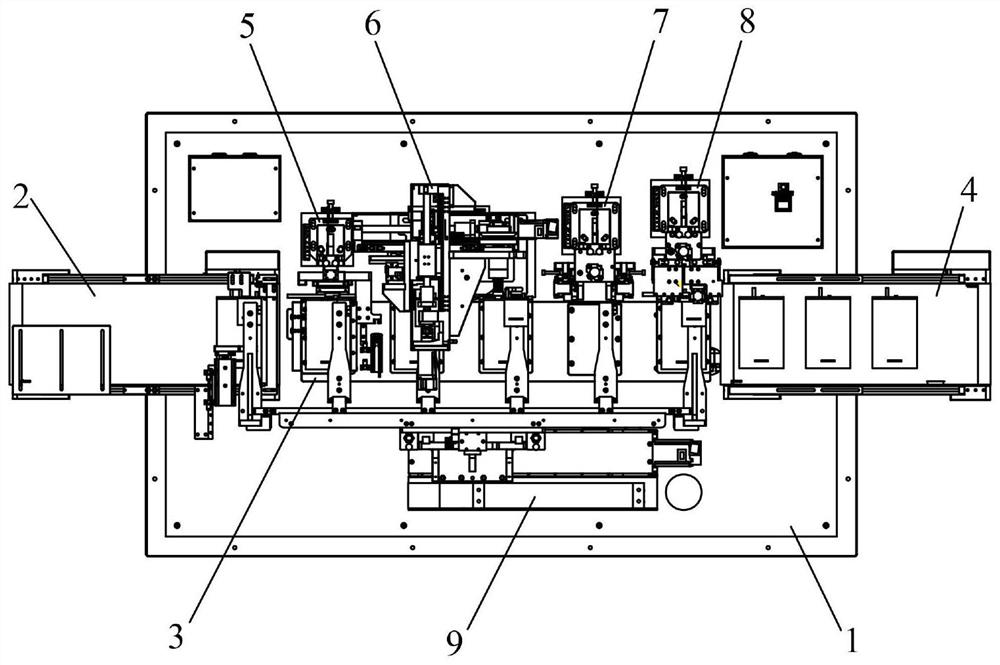

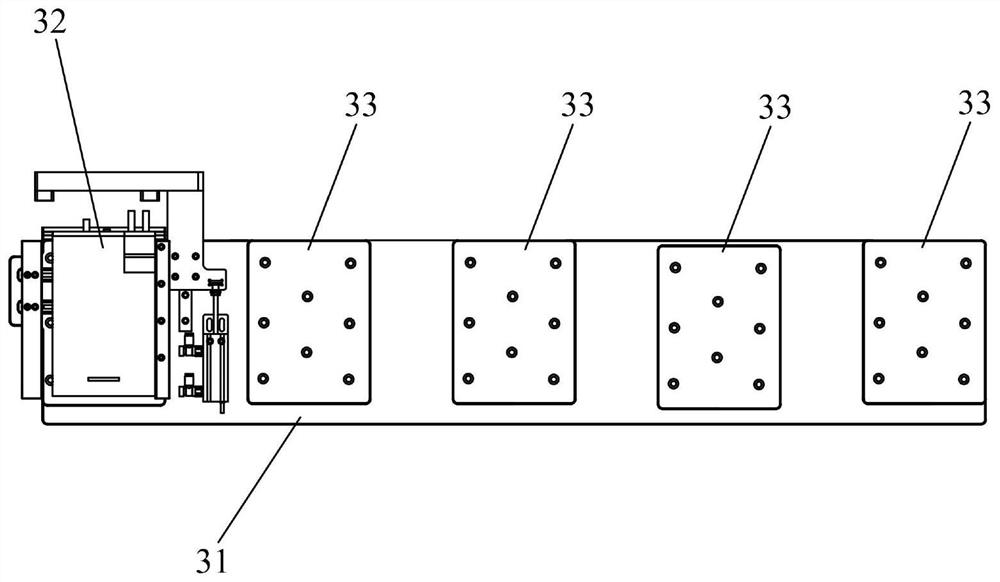

[0045] like Figures 1 to 2 As shown, an automatic battery masking glue sticking device is used to stick glue to the sticking position of the battery packaging bag, including a frame 1 and a feeding mechanism 2 fixed on the frame 1, a transfer mechanism 3, a feeding mechanism Mechanism 4, flattening mechanism 5, masking mechanism 6, upturning mechanism 7, inward folding mechanism 8 and handling manipulator 9, feeding mechanism 2, transfer mechanism 3 and unloading mechanism 4 are arranged in sequence from left to right. The flat mechanism 5, the masking mechanism 6, the turning mechanism 7 and the inward folding mechanism 8 are arranged on one side of the transfer mechanism 3 from left to right. above body 4;

[0046] The transfer mechanism 3 is used to place the battery;

[0047] The flattening mechanism 5 is used to expand the edge of the gluing position;

[0048] The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap