Polyurethane modified carbon nanotube/PLA/PBAT composite material containing sulfonic acid ionic liquid element

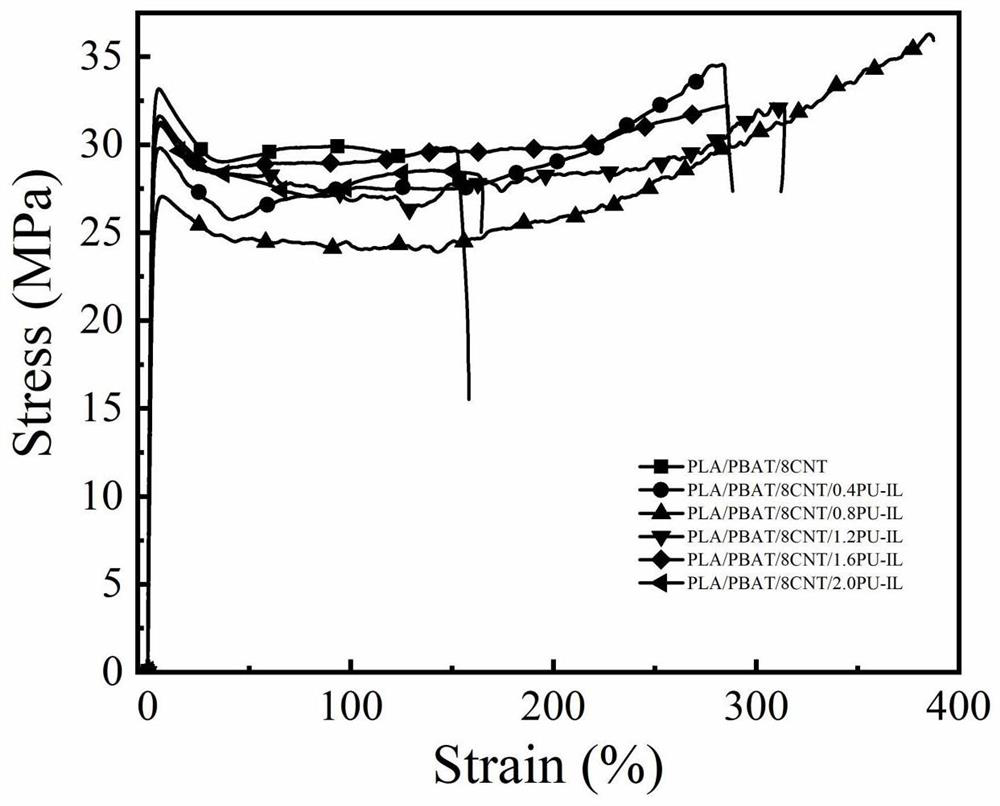

An ionic liquid and composite material technology is applied in the field of polyurethane modified carbon nanotube/PLA/PBAT composite material and its preparation, which can solve the problems of low elongation at break and the inability to reach the application range of PLA composite material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

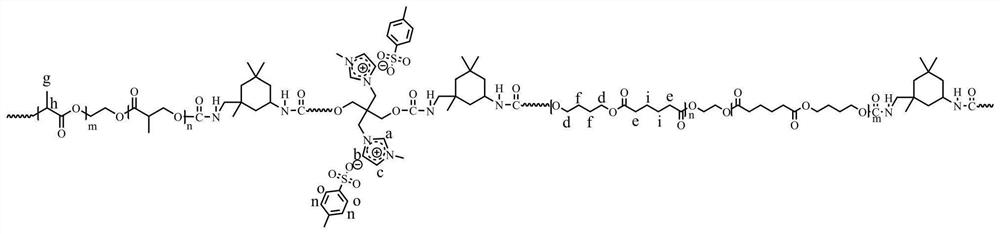

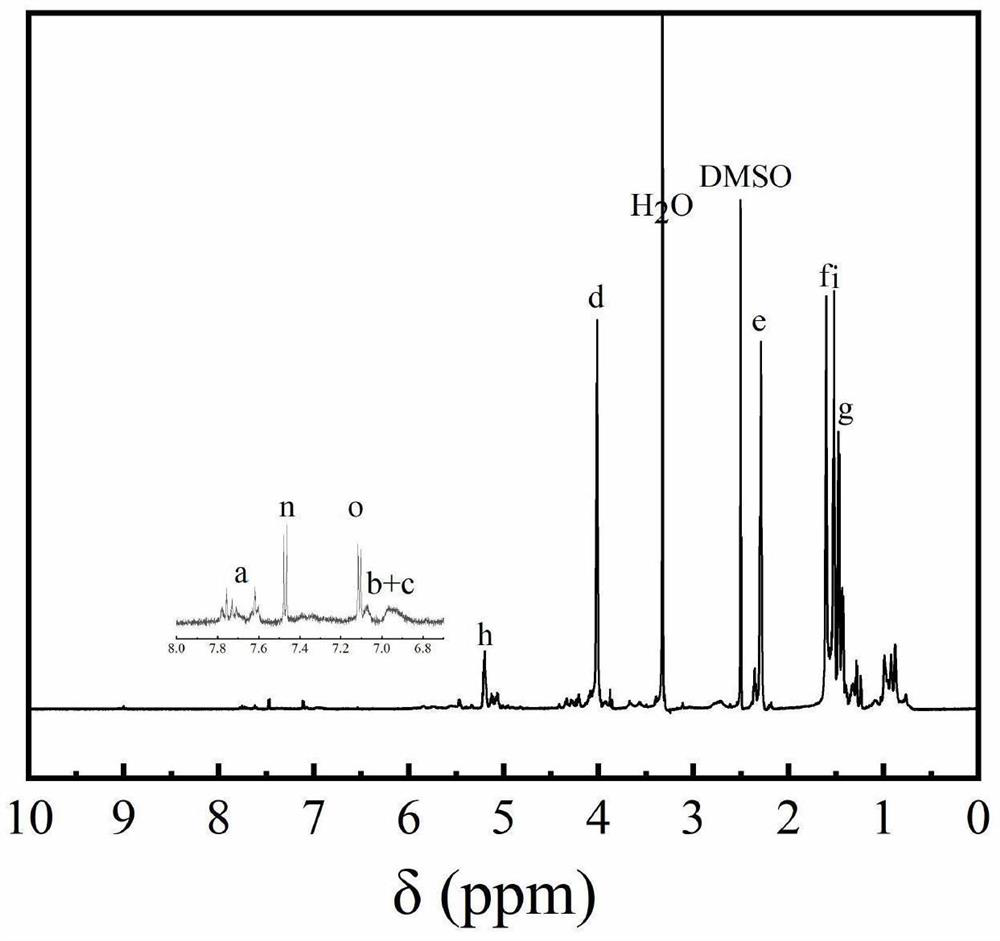

[0027] This embodiment prepares polyurethane (PU-IL) modified carbon nanotube / PLA / PBAT composites containing a sulfonic acid ionic liquid primary according to the following steps:

[0028] (1) 2.5 g of hyeta dikyl alcohol is added to the three flasks, placed in a 150 ° C oil bath, vacuum 30min to remove water, add 5 ml of dimethyl sulfoxide and stirred to polycapric acid The butanediol is dissolved, then 0.222 g of IPDI is slowly added, and 0.2 ml of catalyst DBTDL was added dropwise, and the preservation polymerization was continued for 0.5 hours.

[0029] (2) In another three flask, 2.5 g of polylactide polyol is added, placed in a 150 ° C oil bath, vacuum 30min to remove water, add 5 ml of dimethyl sulfoxide, and stir it to polyolsolycyl ester polyol dissolution. Then, 0.222 gIPDI was slowly added, and 0.2 ml of catalyst DBTDL was added dropwise, and the reaction polymerization was continued for 0.5 hours.

[0030] (3) Add the solution of step (1) to the solution of step (2),...

Embodiment 2

[0035] This embodiment prepares a PU-IL modified carbon nanotube / PLA / PBAT composite according to the following steps:

[0036] (1) 2.5 g of hyeta dikyl alcohol is added to the three flasks, placed in a 150 ° C oil bath, vacuum 30min to remove water, add 5 ml of dimethyl sulfoxide and stirred to polycapric acid The butanediol is dissolved, then 0.222 g of MDI is slowly added, and 0.2 ml of catalyst DBTDL was added dropwise, and the preservation polymerization was continued for 0.5 hours.

[0037] (2) In another three flask, 2.5 g of polylactide polyol is added, placed in a 150 ° C oil bath, vacuum 30min to remove water, add 5 ml of dimethyl sulfoxide, and stir it to polyolsolycyl ester polyol dissolution. Then, 0.222 g of MDI was slowly added, and 0.2 ml of catalyst DBTDL was added dropwise, and the preservation polymerization was continued for 0.5 hours.

[0038] (3) Add the solution of step (1) to the solution of step (2), then add 1.065 g n, N-neiteriol pair (N-methylimidazo...

Embodiment 3

[0043] This embodiment prepares a PU-IL modified carbon nanotube / PLA / PBAT composite according to the following steps:

[0044] (1) 2.5 g of hyeta dikyl alcohol is added to the three flasks, placed in a 150 ° C oil bath, vacuum 30min to remove water, add 5 ml of dimethyl sulfoxide and stirred to polycapric acid The butanediol is dissolved, then 0.222 g of TDI is slowly added, and 0.2 ml of catalyst DBTDL was added dropwise, and the preservation polymerization was continued for 0.5 hours.

[0045] (2) In another three flask, 2.5 g of polylactide polyol is added, placed in a 150 ° C oil bath, vacuum 30min to remove water, add 5 ml of dimethyl sulfoxide, and stir it to polyolsolycyl ester polyol dissolution. 0.222 g of Tdi was then slowly added, and 0.2 ml of catalyst DBTDL was added dropwise, and the preservation polymerization was continued for 0.5 hours.

[0046] (3) Add the solution of step (1) to the solution of step (2), then add 1.065 g n, N-neiteriol pair (N-methylimidazol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap