Microbial fermentation tank capable of defoaming

A technology of microbial fermentation and fermenter, which is applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, enzymology/microbiology device, etc. Eliminate foam, affect the fermentation efficiency of the fermenter and other problems, so as to improve the stirring effect, the fermentation work is smooth, and the safe use is ensured.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

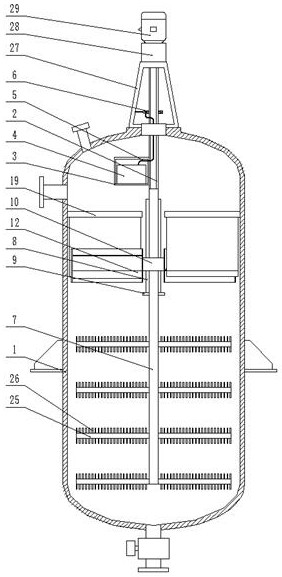

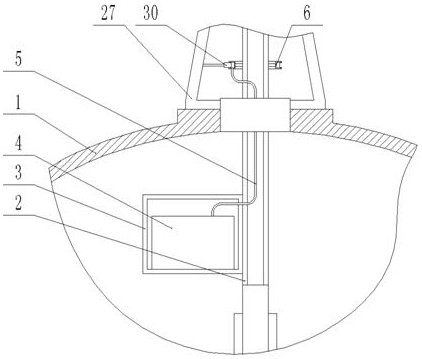

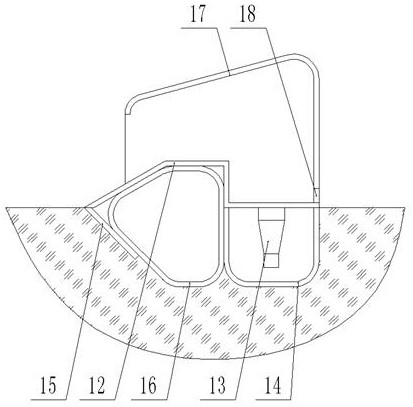

[0028] The present invention will be specifically described below in conjunction with the accompanying drawings, such as Figure 1-6 shown.

[0029] In this device, the device is powered by being connected to an external power source, and the external power source is electrically connected to the drive motor 29 and the electric slider 30 for power supply, so as to control the operation of the device.

[0030] The creative point of this scheme is to adjust the structural design of the collection ultrasonic defoaming device, combined with the attachment figure 1 , attached figure 2 , attached image 3 and attached Figure 4The adjustment collection type ultrasonic defoaming device includes a stirring sleeve 2 on the inside of the fermentation tank body 1, the stirring sleeve 2 is movably connected with the fermentation tank body 1 through a mechanical seal, and a sealing box is installed on one side surface of the stirring sleeve 2 Body 3, an ultrasonic generator 4 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com