Reverse construction method for installing support after rotating

A construction method and a technology for installing bearings, which are applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., can solve problems such as hindering bridge rotation and increasing the difficulty of rotation, and achieve simple and practical construction processes, high construction efficiency, and reduced effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

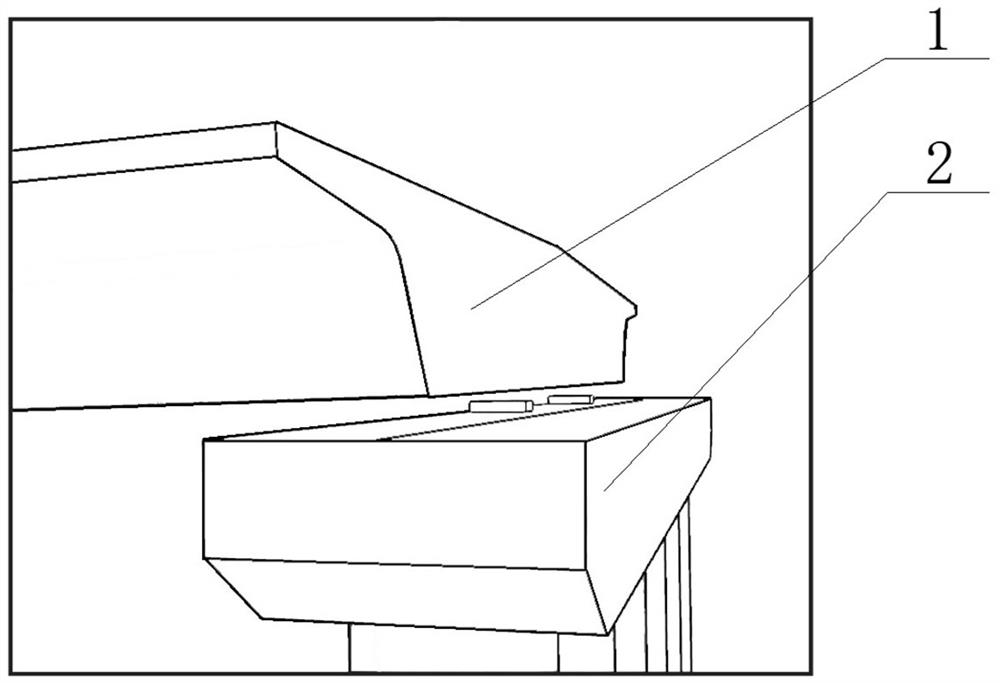

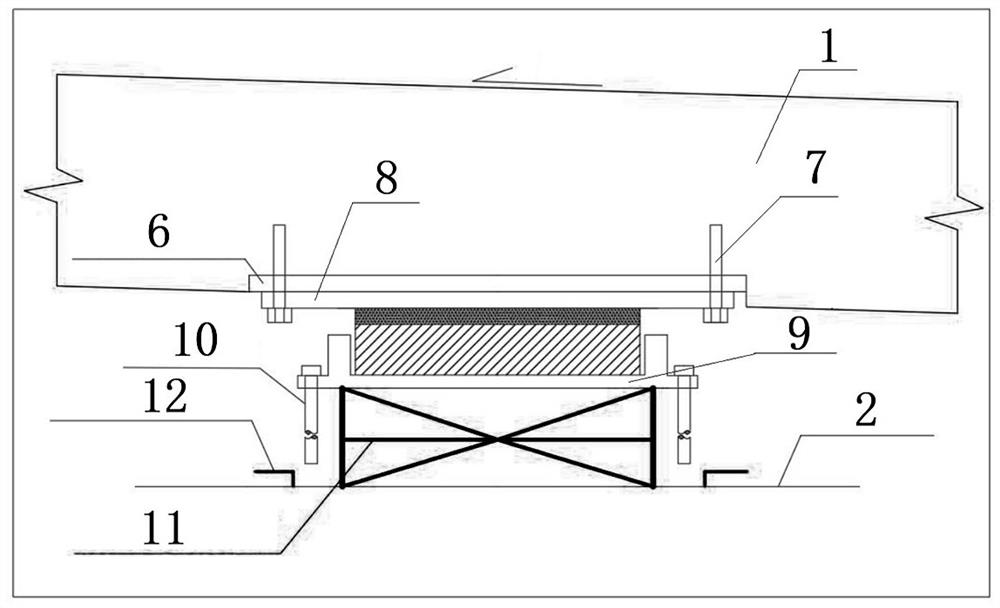

[0024] Example: such as Figure 1-4 As shown, this embodiment involves a reverse construction method of first rotating the body and then installing the support. The construction method includes the following steps:

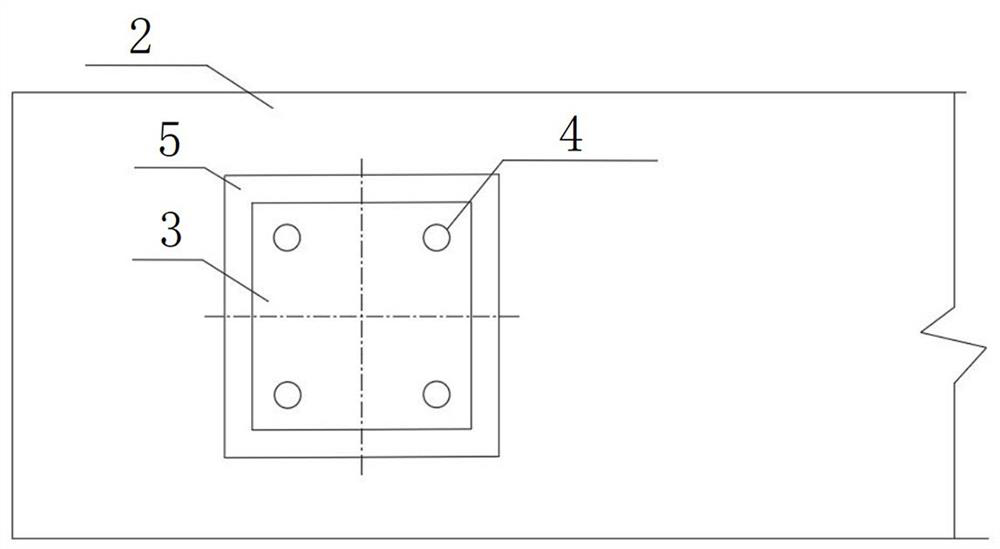

[0025] 1. When the box girder cantilevered to the last section, install the pre-embedded steel plate 6 and the reserved anchor sleeve in the beam body 1 according to the designed position, wherein the pre-embedded steel plate 6 is located at the bottom of the beam body 1, that is, the pre-embedded steel plate 6 bottom surfaces can be used as the beam body 1 bottom surface. In this embodiment, the embedded steel plate 6 is fixed by the upper screw in the beam body 1 to ensure the horizontal setting of the embedded steel plate 6 . The four corners of the pre-embedded steel plate 6 are each provided with a reserved anchor hole 4, and the position and quantity of the reserved anchor sleeve match the position and quantity of the reserved anchor holes 4 on the pre-embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com