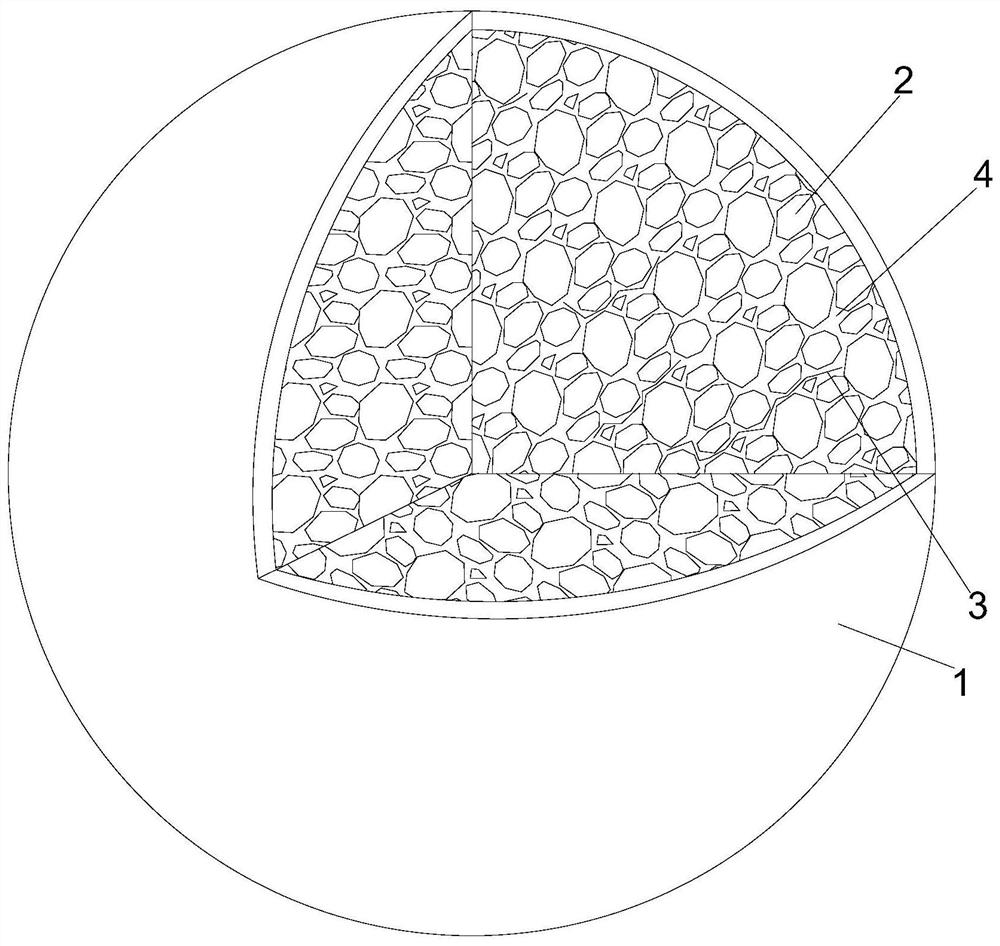

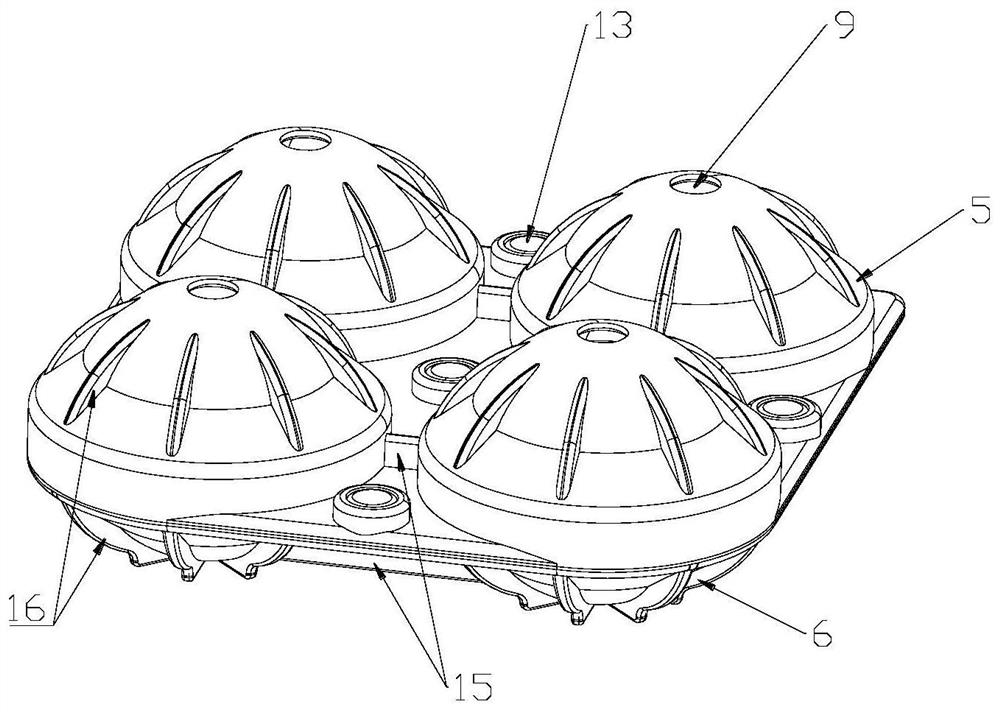

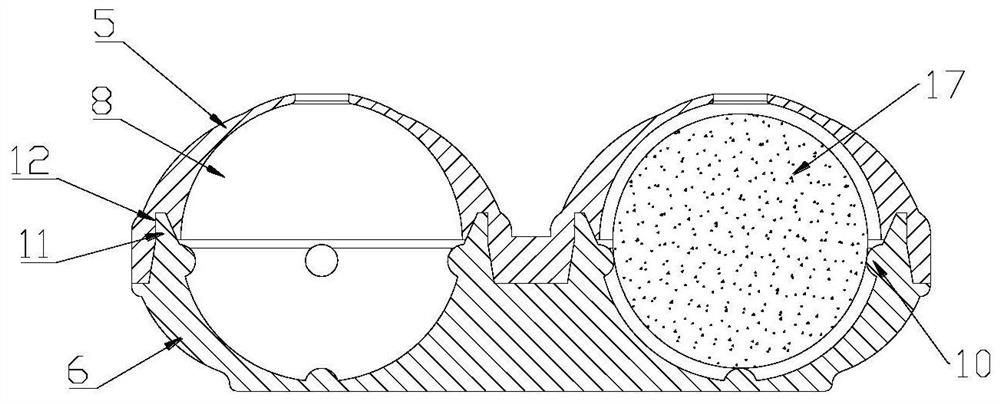

Drilling leaking stoppage small ball and preparation method thereof

A technology of small balls and spherical cavities, applied in drilling compositions, chemical instruments and methods, earthwork drilling and mining, etc., can solve problems such as difficulty in bearing pressure, failure to enter gaps, and easy bridging of large particles to achieve reliable plugging leaky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on embodiments of the present invention, those of ordinary skill in the art will belong to the scope of the present invention without making creative labor. It will be appreciated that the accompanying drawings only provide reference and description, are not intended to limit the invention. The connection relationship shown in the drawing is merely described in order to facilitate clear description, and no connection is limited.

[0030] All technical and scientific terms used herein are commonly understood by those skilled in the art of the present invention, unless otherwise defined. The terminology used in the specification of the present invention is intended to descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com