Hidden connecting piece and drill bit matched with connecting piece for use

A connecting piece and hidden technology, which is applied in the direction of connecting components, thin-plate connection, drilling repair, etc., can solve the problems of large cost expenditure, lower furniture product grade, high purchase and use cost, etc., so as to improve the aesthetics and grade, improve Market penetration rate, reducing the effect of product upgrades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment includes a self-tapping part 1, a connecting rod 2, a wing 3 and a runner 4, which can be made of metal or PVC plastic.

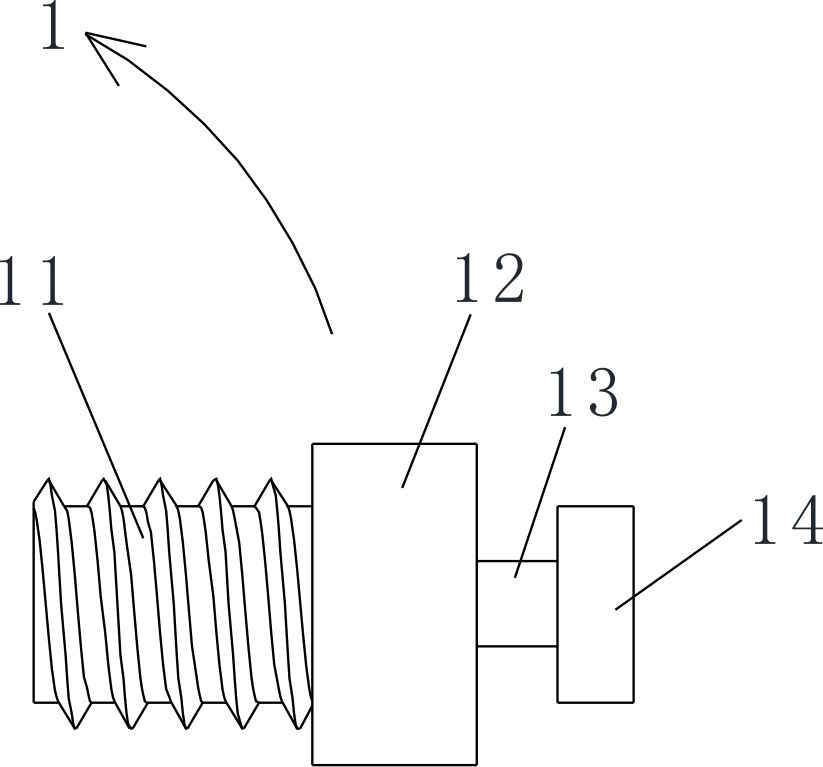

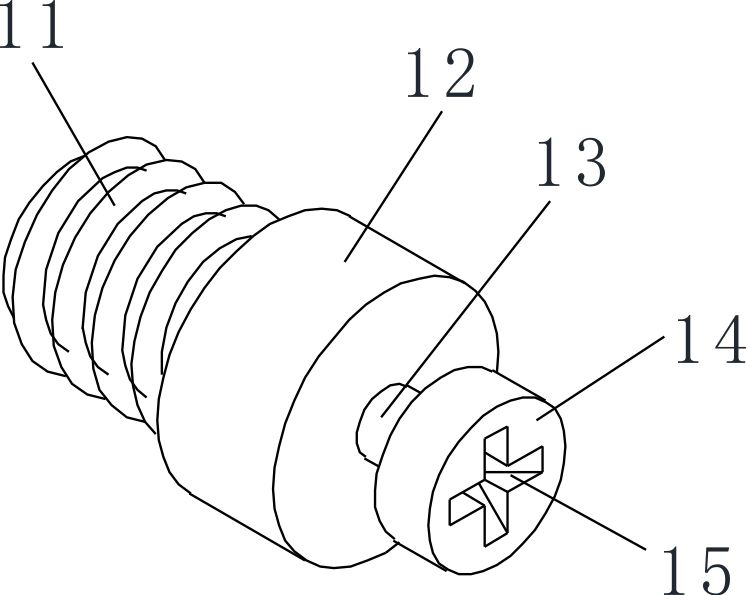

[0041] see figure 1 and figure 2 , The self-tapping part 1 is composed of a threaded part 11, a shoulder 12, a transition part 13 and a locking part 14 in sequence, the threaded part 11 is provided with threads, the diameter of the shoulder 12 is larger than the diameter of the threaded part 11, and the transition part The diameter of 13 is smaller than that of the locking part 14, and the top end of the locking part 14 is provided with a cross groove 15 for use with a Phillips screwdriver.

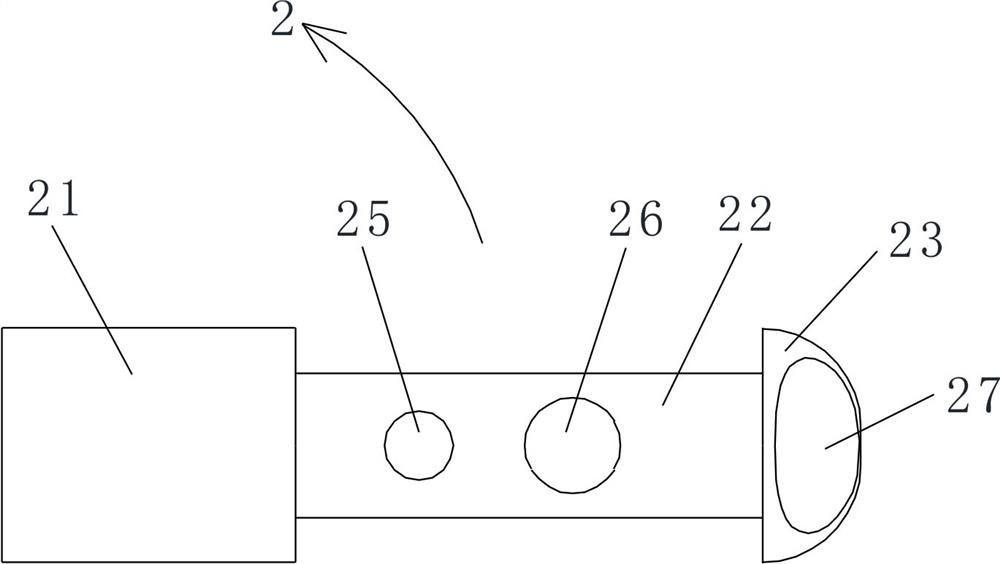

[0042] see Figure 3-Figure 6 , The connecting rod 2 is sequentially composed of a connecting portion 21 , a shaft portion 22 and a tail portion 23 of an integral structure. The diameter of the connecting part 21 is the same as that of the shoulder 12, and the end of the connecting part 21 is provided with a concave locking groove 24, and the...

Embodiment 2

[0055] see Figure 31-Figure 34 , the wheel mounting portion 26 in this embodiment is a concave U-shaped groove, and the wheel lever 42 is rotatably located in the wheel mounting portion 26 . The rest of the structure and working process are the same as those in Embodiment 1, and will not be repeated here.

[0056] In addition to being used for connecting furniture parts, the present invention can also be used for connecting machine parts and other occasions that need to be connected, and is not limited to the specific embodiments of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com