Flow adaptation structure of ultralow-temperature integrated ball valve

An adaptive structure and integrated technology, applied in the direction of valve shell structure, valve details, valve devices, etc., can solve the problems of poor explosion-proof performance of valves, potential safety hazards in use, and inability to control the flow rate of liquid media well, etc., to achieve Good explosion-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

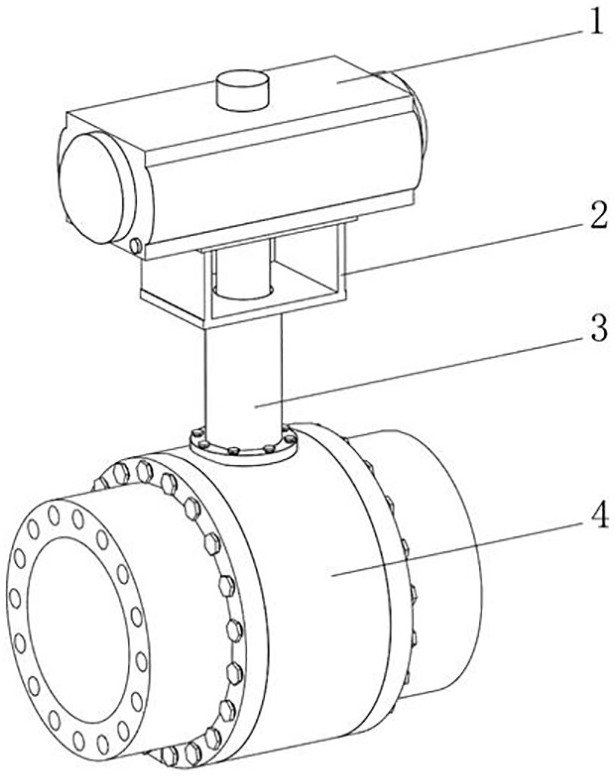

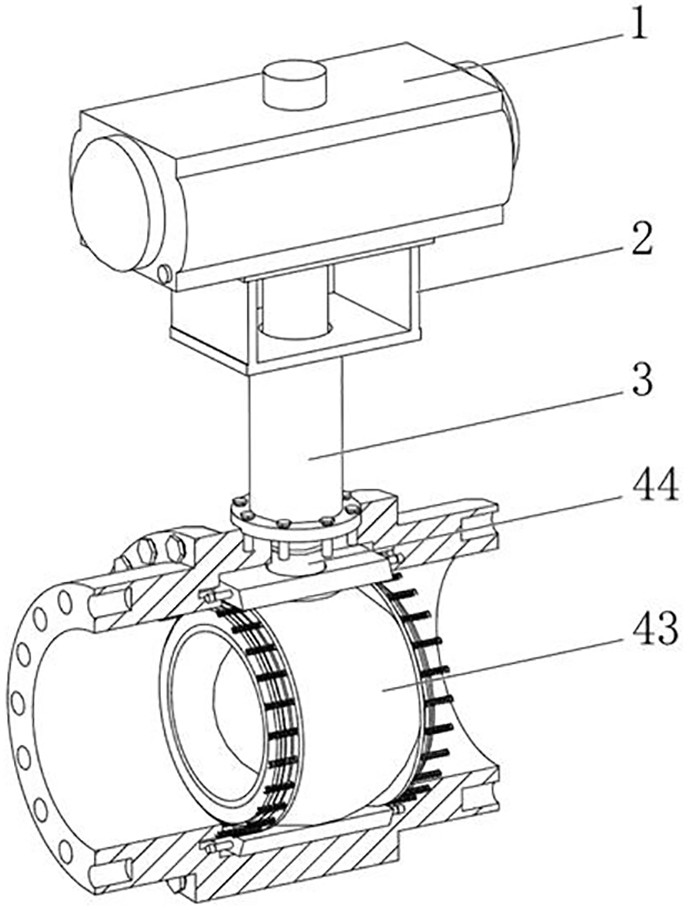

[0017] An ultra-low temperature integrated ball valve adopting the structure of the present invention includes a pneumatic actuator 1, the pneumatic actuator 1 is fixedly connected with a heat preservation pipe 3 through a support frame 2 arranged at the bottom of the heat preservation pipe 3, and the bottom of the heat preservation pipe 3 is threadedly connected with a valve through several groups of bolts Body 4.

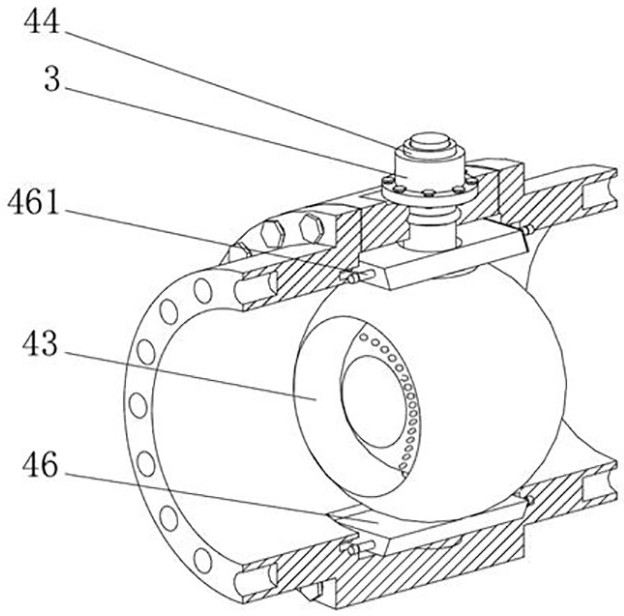

[0018] The flow adaptation structure of the ultra-low temperature integrated ball valve of the present invention includes a sphere 43 which is rotated and arranged in the valve body 41 , the upper and lower sides of the sphere 43 are provided with receiving plates 46 , and the receiving plates 46 are sleeved on the outside of the valve stem 44 , The receiving plate 46 is designed to be trapezoidal, and the two sides of the trapezoid are designed to be arc-shaped. The valve body 41 is provided with an arc-shaped groove 47, and the outside of the receiving plate 46 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com