Card feeding mechanism with preheating function

A pre-heating and card-feeding technology, applied to the analysis of materials, instruments, etc., can solve the problems of low diagnostic efficiency, tediousness, and excessive time consumption, and achieve the effects of ensuring stability, facilitating heating, and avoiding excessive rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

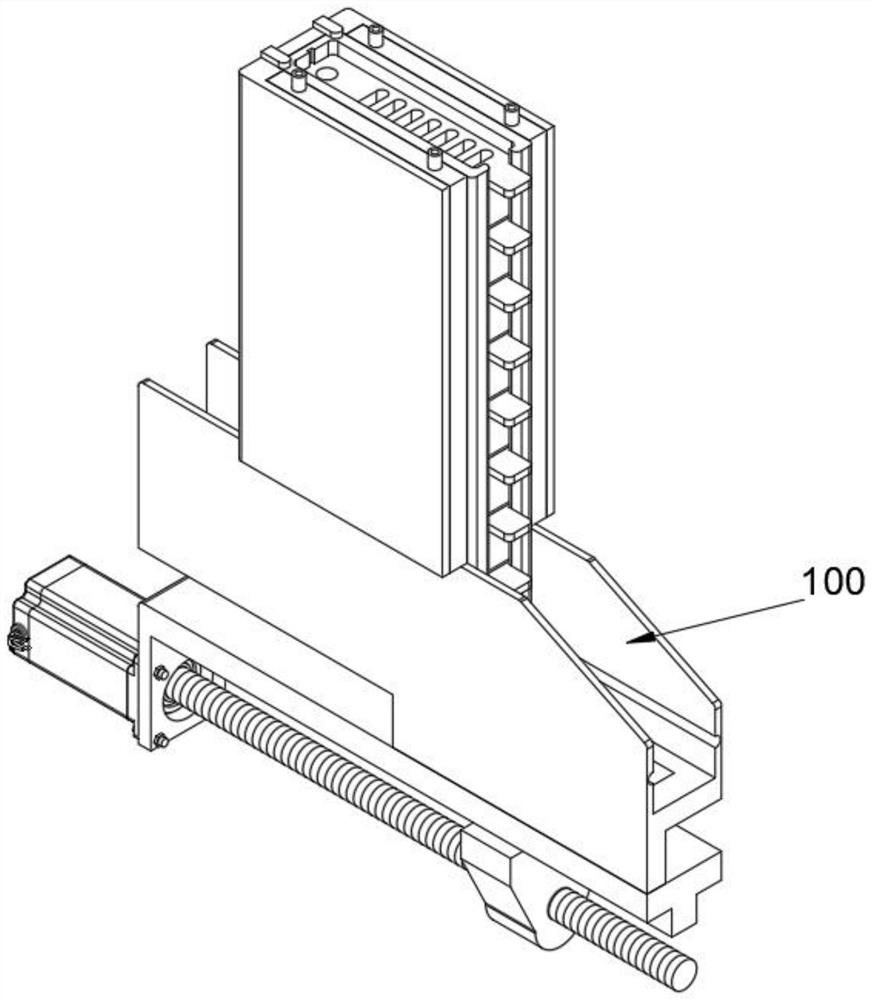

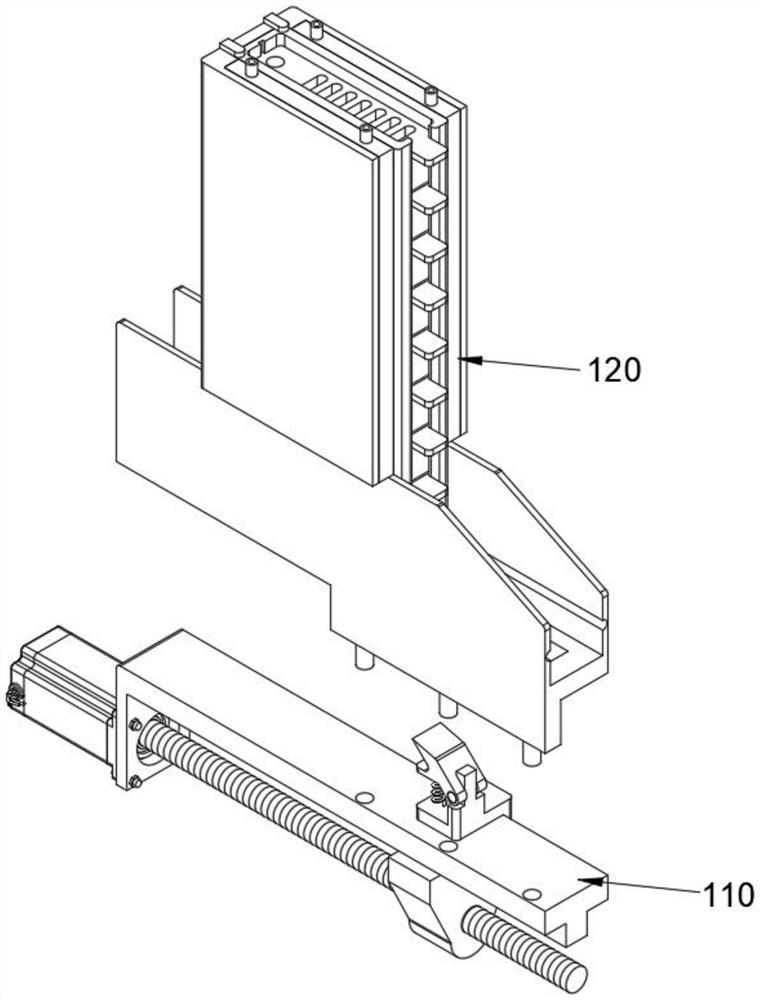

[0042] see Figure 1-Figure 6 As shown, the purpose of this embodiment is to provide a card feeding mechanism with a preheating function, including a card feeder 100, and the card feeder 100 at least includes:

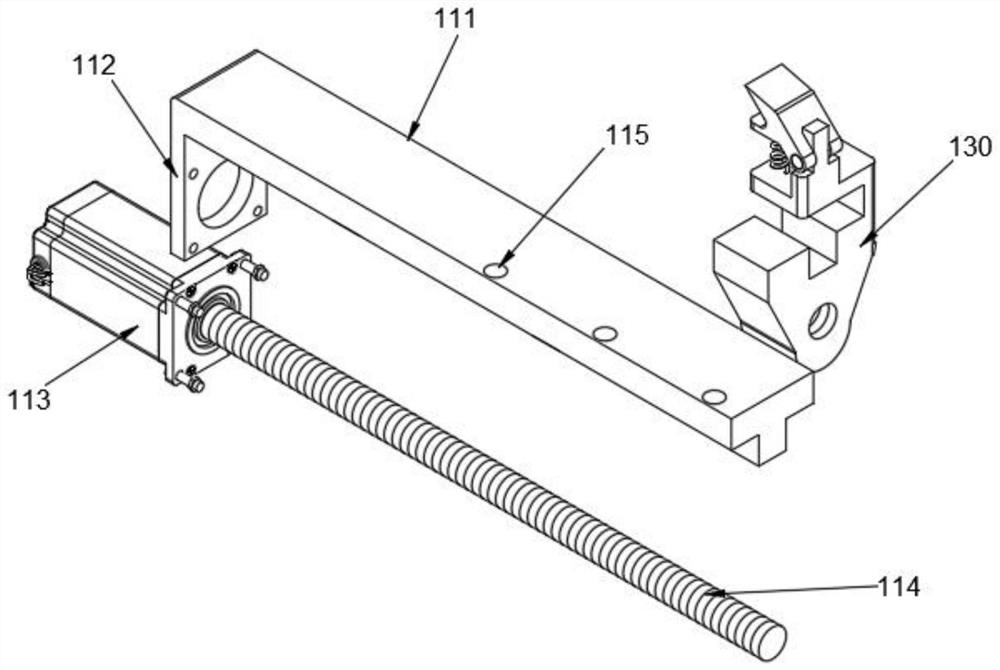

[0043] The power body 110, the power body 110 includes a sliding plate 111, the sliding plate 111 is a "T"-shaped structural plate, the side of the sliding plate 111 is provided with a fixed plate 112, the fixed plate 112 is fixed with a servo motor 113 by bolts, and the servo motor 113 passes through The fixed plate 112 is connected with a threaded rod 114 for transmission, and the surface of the threaded rod 114 is connected with a reciprocating body 130. The reciprocating body 130 includes a reciprocating plate 131, and the bottom of the reciprocating plate 131 is provided with a threaded opening 133 that runs through its surface, and the threaded rod 114 passes through the threaded opening 133 It is threadedly connected with the threaded port 133, and the top of th...

Embodiment 2

[0050] see Figure 7 As shown, in order to ensure the reciprocating movement of the reciprocating body 130 when repeatedly pushing and replacing the reagent strip 125, this embodiment makes the following improvements on the basis of embodiment 1:

[0051] Wherein, the top of the reciprocating plate 131 is provided with a rotating shaft 135, and the bottom of the pushing plate 132 is provided with a slot 136 correspondingly. The circular piercing is connected with the push plate 132 in rotation, and the back and forth movement of the push plate 132 is facilitated by being provided with the reciprocating plate 131 and the push plate 132 which are rotatably connected.

[0052] This embodiment is driven by the threaded rod 114 to slide along the slide plate 111 during specific use. After the push plate 132 pushes out the bottom reagent strip 125, the multiple reagent strips 125 in the magazine frame 123 move down along the trend, and the push plate 132 is pressed. Make the push p...

Embodiment 3

[0056] see Figure 8-Figure 9 As shown, in order to speed up the temperature of the reagent strip 125 to normal temperature when repeatedly pushing and replacing the reagent strip 125, this embodiment makes the following improvements on the basis of embodiment 1:

[0057] Wherein, a temperature control body 140 is provided on the surface of the clip frame 123, and the temperature control body 140 includes a heat shield 141 connected to the clip frame 123. The soaking plate 142 in contact with the surface of the magazine frame 123 has a heating groove 143 inside the soaking plate 142, and an electric heating rod 144 is arranged in the heating groove 143. By being provided with a temperature control body 140, heat can be generated to the magazine frame 123. The reagent strip 125 inside is heated to speed up the temperature of the reagent strip 125 to normal temperature, which is beneficial to improve the diagnostic efficiency.

[0058] In the specific use of this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com