Gas mass flow controller

A gas mass flow, controller technology, applied in the direction of fluid pressure control, non-electric variable control, electric fluid pressure control, etc. environmental issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

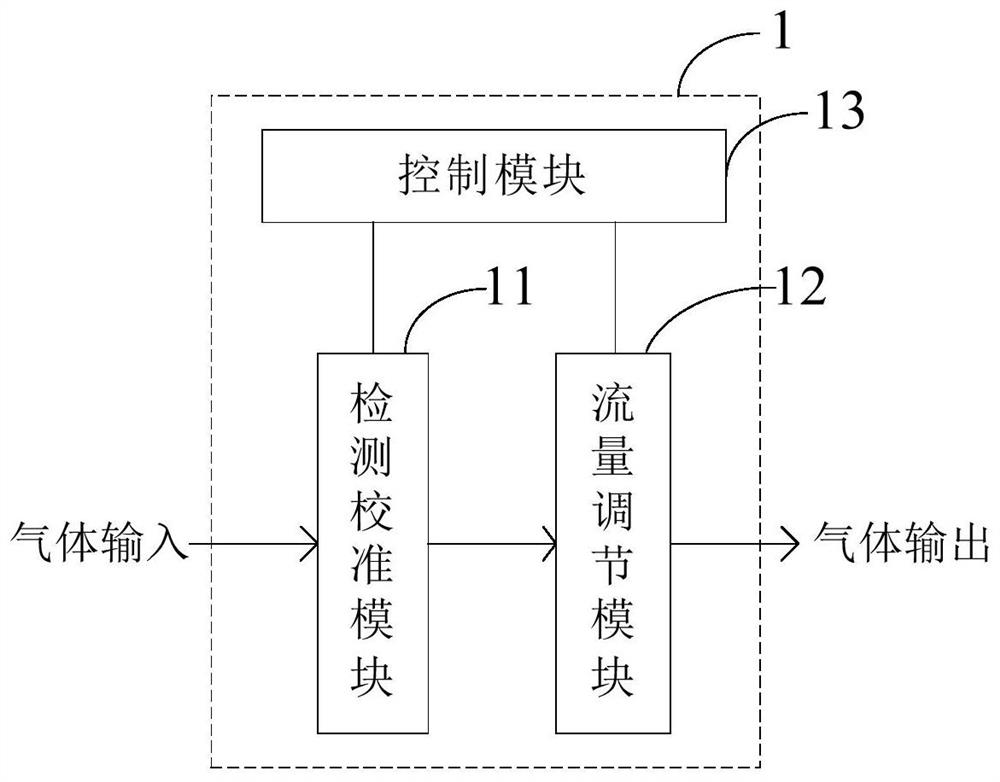

[0062] see figure 1 , the gas mass flow controller 1 provided in this embodiment includes a detection and calibration module 11, a flow adjustment module 12 and a control module 13, wherein the detection and calibration module 11 is used to receive the input gas to be controlled and deliver it to the flow rate The adjustment module 12, and the detection and calibration module 11 can detect the actual flow value of the gas to be controlled; the flow adjustment module 12 is used to output the above-mentioned gas to be controlled, and can detect and adjust the flow output value of the gas to be controlled.

[0063] The control module 13 is used to selectively switch between the detection calibration mode and the real-time detection mode. In the detection calibration mode, the control module 13 is used to control the detection calibration module 11 and the flow adjustment module 12 to detect the above-mentioned actual flow value and flow output respectively. value, and according t...

no. 2 example

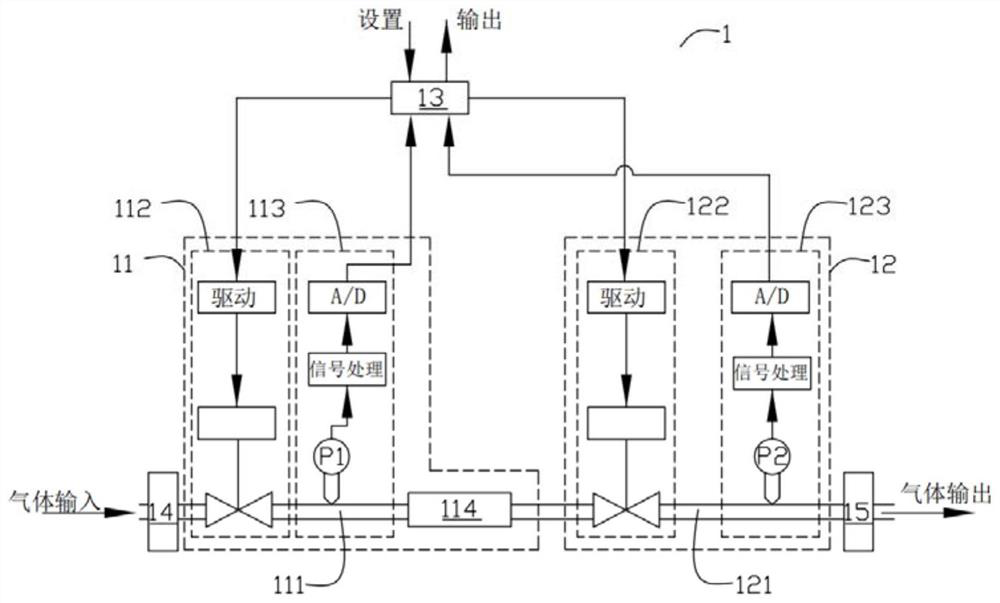

[0069] see figure 2 , the gas mass flow controller 1 provided in this embodiment is a specific implementation of the above-mentioned first embodiment. Specifically, the detection and calibration module 11 includes an inlet valve group and a calibration cavity 114 , wherein the inlet valve group and the calibration cavity 114 The gas end is connected, and the inlet valve group is used for receiving the input gas to be controlled, and can detect the first air pressure value of the calibration chamber 114 , send it to the control module 13 , and open or close the intake end of the calibration chamber 114 .

[0070] In some optional embodiments, the above-mentioned inlet valve group may include an intake air passage 111 , an on-off valve 112 and a first pressure detection unit 113 , wherein the intake end of the intake air passage 111 is used to receive the input pending control gas, the outlet end of the intake air passage 111 is connected to the intake end of the calibration ch...

no. 3 example

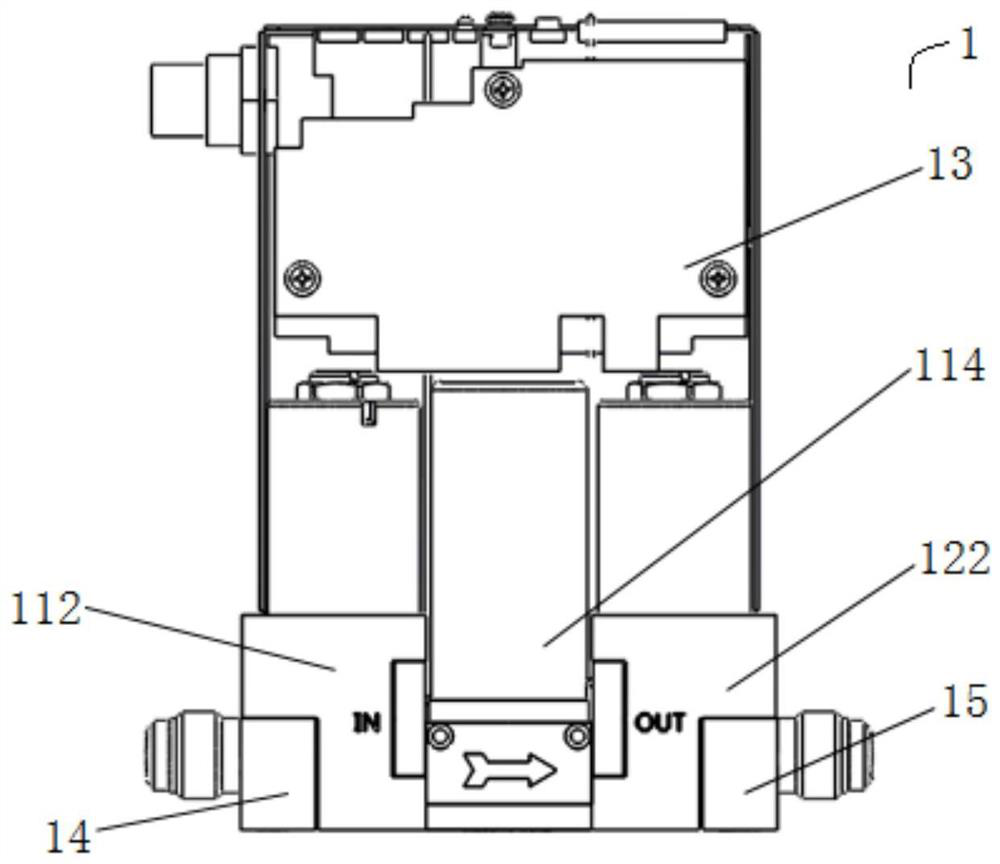

[0106] Please also refer to Figure 8A and Figure 8B , the gas mass flow controller 1 ′ provided in this embodiment is an improvement made on the basis of the above-mentioned second embodiment, specifically, on the basis of the gas mass flow controller 1 adopted in the above-mentioned first embodiment , the gas mass flow controller 1' provided in this embodiment further includes an inlet adapter module 16, the inlet adapter module 16 includes an adapter, and an air inlet channel (not shown in the figure) is arranged in the adapter, The intake end of the intake passage is used to receive the input gas to be controlled, and the outlet end of the intake passage is used to communicate with the intake end of the above-mentioned outlet valve group (ie, the intake end of the outlet passage in the second base 124 ). ) communicates with each other; the above-mentioned adapter is detachably connected with the above-mentioned outlet valve group (ie, the second base 124 ). In this way,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com