Cable sheath-core separation equipment for new energy equipment recovery

A technology for new energy equipment and separation equipment, which is applied in recycling technology, electronic waste recycling, circuits, etc., and can solve the problems of cable fixation and difficult cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

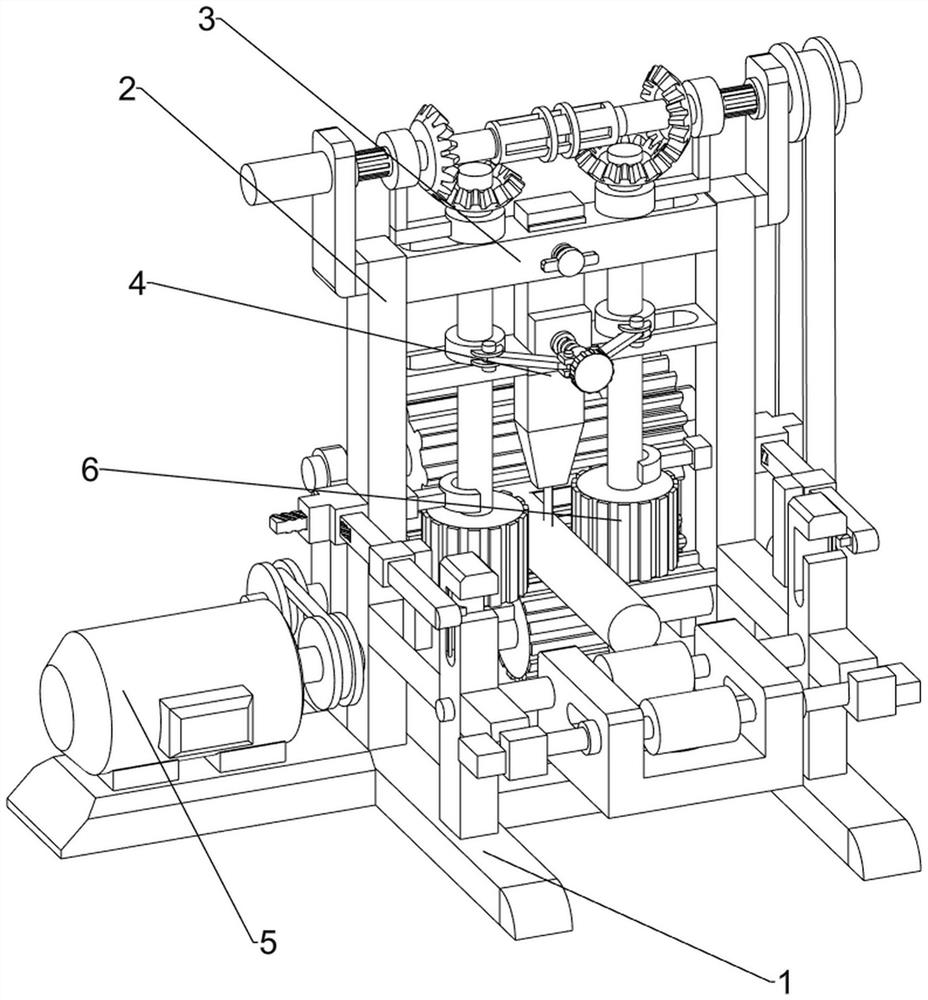

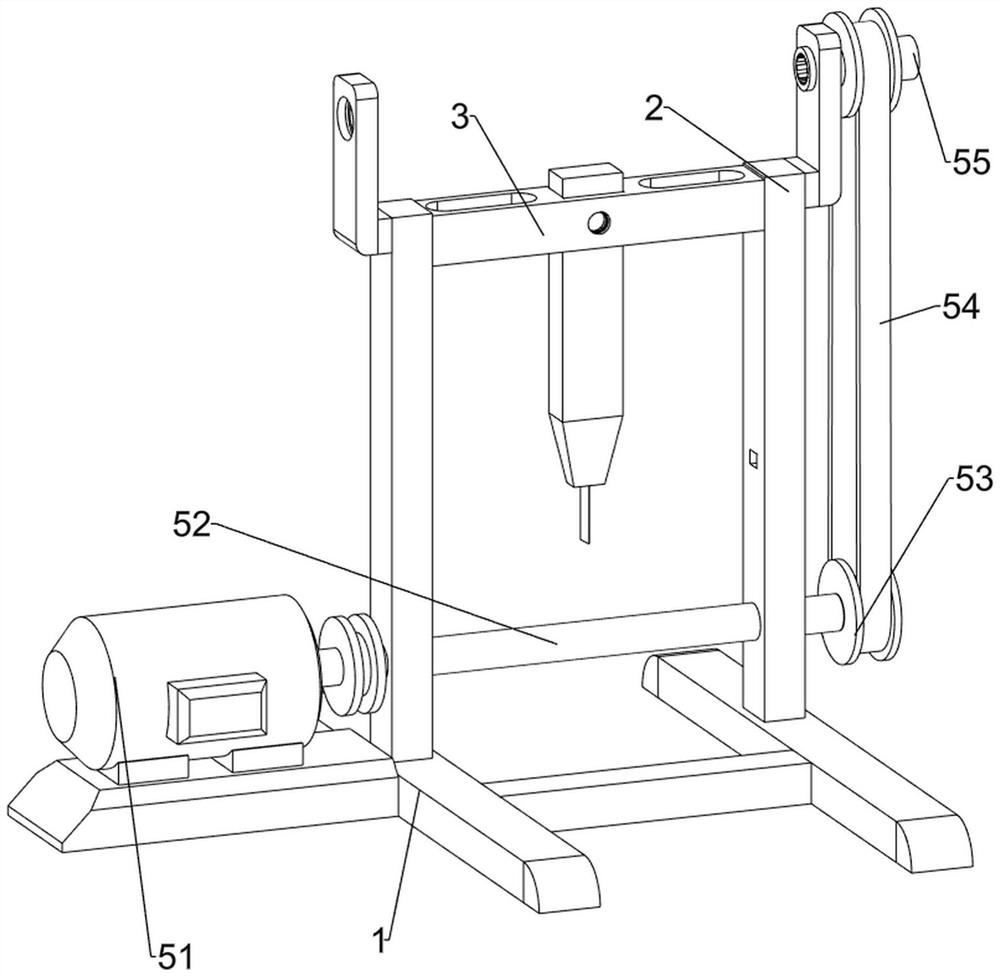

[0030] A cable skin-core separation device for recycling new energy equipment, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a first bracket 2, a first fixed frame 3, a cutting knife 4, a driving mechanism 5 and a fixed delivery mechanism 6, and the rear side of the top of the base 1 is symmetrically provided with a first bracket 2, and the first bracket 2 The first fixed frame 3 is arranged between the upper parts, the middle part of the first fixed frame 3 is slidingly provided with a cutting knife 4, the top of the base 1 is provided with a driving mechanism 5, and a fixed conveyor is provided between the first bracket 2 and the first fixed frame 3. Institution 6.

[0031] When people need to use this equipment, first insert the head end of the cable between the fixed conveying mechanism 6, fix the cutting knife 4 according to the size of the cable, and then start the driving mechanism 5, so that the driving mechanism 5 drives the fixed conveyi...

Embodiment 2

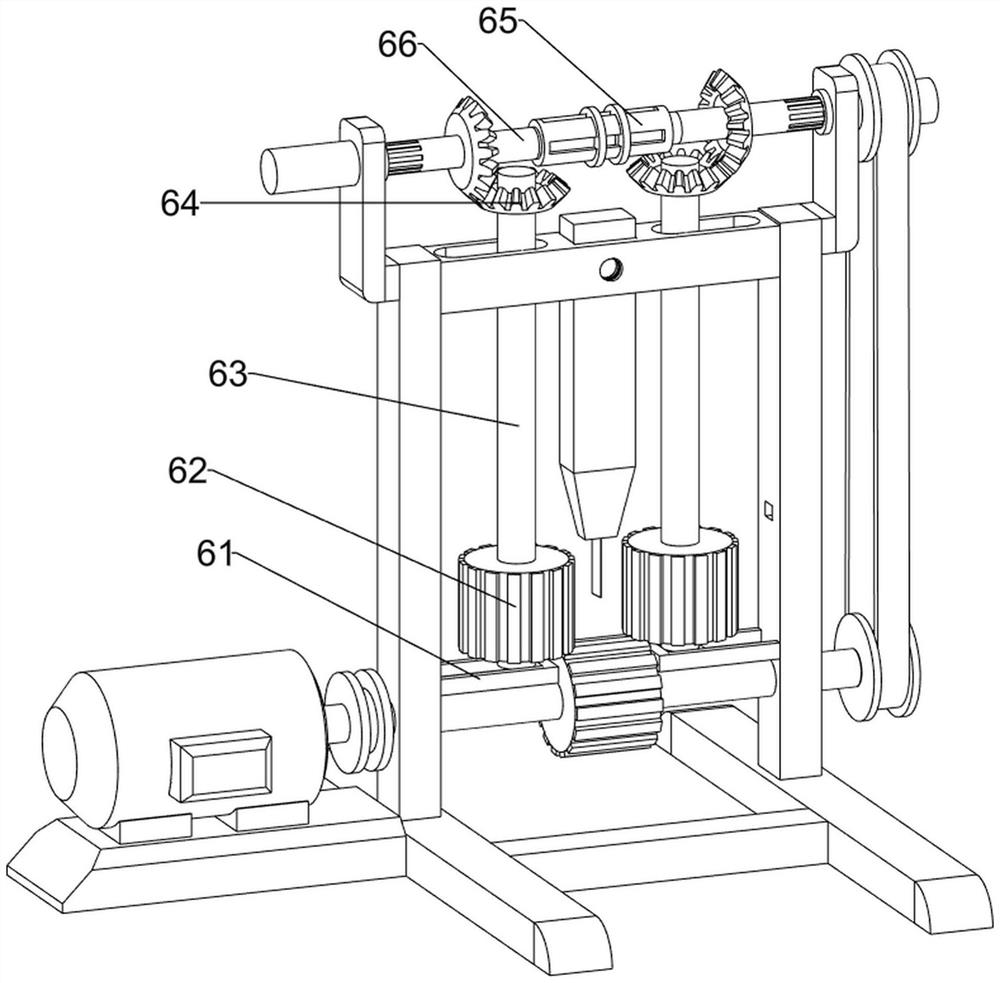

[0036] On the basis of Example 1, such as Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, it also includes a second fixed mount 7, a splint 8, a first thumb screw 9, a guide rod 10, a first fixed block 11, a connecting rod 12, a nut 13 and a second thumb screw 14, and the second rotating sleeve 66 is equipped with a second fixed mount 7 in a sliding manner, and the second fixed mount 7 is connected with the first rotating rod 63 and the bevel gear 64. The front side of the first fixed mount 3 is threaded with the first hand screw 9 , the rear side rotation of the first hand screw 9 is provided with a splint 8, the splint 8 cooperates with the cutting knife 4, and the inner side of the first support 2 top is provided with a guide rod 10, and the first rotation rod 63 is positioned on the guide rod 10. Sliding up, the first rotating rod 63 is provided with the first fixed block 11, the front side of the first fixed block 11 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com