Unattended oil field transfer station robot based on image recognition system

An image recognition and robot technology, applied in the field of robotics, can solve the problems of easily affecting camera imaging, accumulating dust, inconvenient camera shading, etc., to achieve the effects of convenient use, easy shading, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

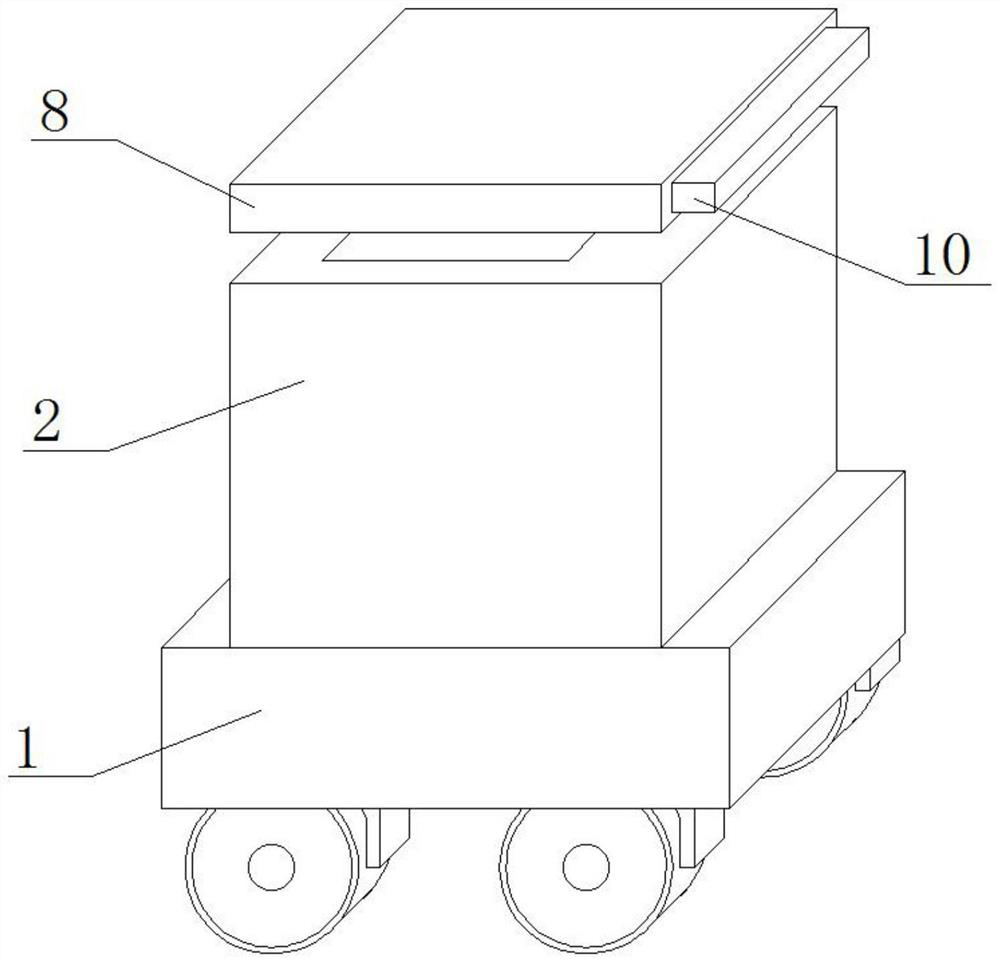

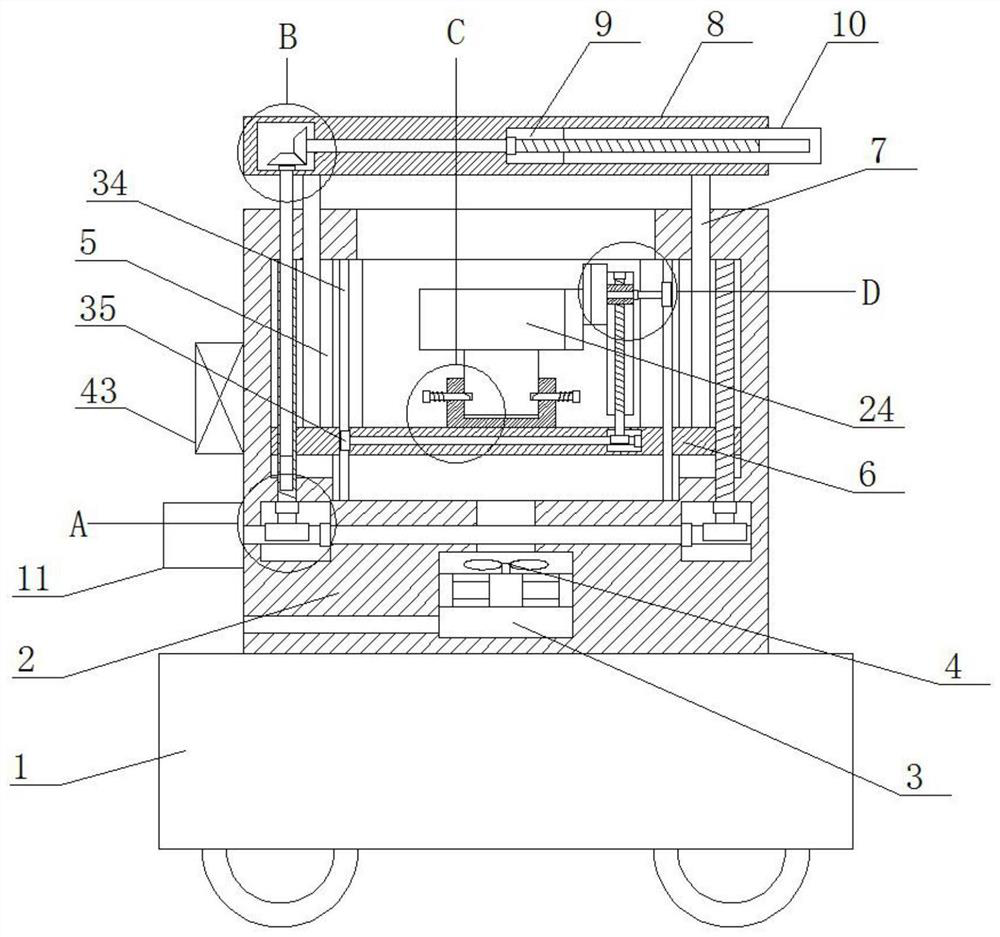

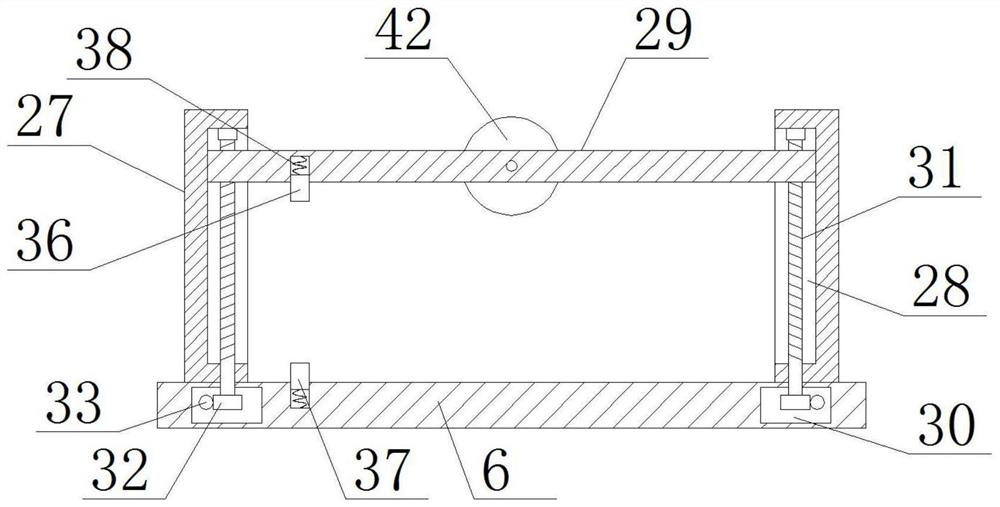

[0029] refer to Figure 1-7 , an unattended oil field switching station robot based on an image recognition system, comprising a robot main body 1, a storage box 2 is installed on the top of the robot main body 1 through bolts, and a first installation slot 3 is opened in the storage box 2, and the first installation A heat dissipation fan 4 is fixedly installed in the groove 3 by bolts, and the inner walls of both sides of the storage box 2 are provided with a first chute 5, and the same mounting plate 6 is slidably installed in the two first chute 5, and the top of the mounting plate 6 Mounting seat 22 is fixedly installed by welding, and the top of mounting seat 22 is provided with the 3rd chute, and connecting post 23 is slidably installed in the 3rd chute, and the top of connecting post 23 is fixed with camera 24 by bolt, on the mounting plate 6 A lifting mechanism is provided, and the top inner walls of the two first slide grooves 5 are provided with first sliding holes,...

Embodiment 2

[0039] The difference with Embodiment 1 is that the outside of the motor 11 is fixedly connected to one side of the storage box 2, two symmetrical first empty slots 12 are opened in the storage box 2, and a first Through hole, the first through hole communicates with the two first empty slots 12, the first worm 13 is installed in rotation in the first through hole, one end of the first worm 13 is fixedly connected with the output shaft of the motor 11 by welding, the two second The bottom inner wall of a chute 5 is provided with a second through hole, and the two second through holes communicate with the two first empty slots 12 respectively, and the mounting plate 6 is provided with two symmetrical first threaded holes, and the two second through holes communicate with each other respectively. A first threaded mandrel 14 is installed in a threaded hole, and one end of the two first threaded mandrels 14 is fixedly installed with a first worm wheel 15 by welding, and the two fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com