Camera module baking monitoring system and method

A technology of camera module and monitoring system, which is applied in the testing of machines/structural components, measuring devices, image communication, etc. It can solve problems such as incorrect baking temperature, affecting test results, and inaccurate baking time, and achieves the goal of solving the problem of baking The effect of not roasting at a constant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

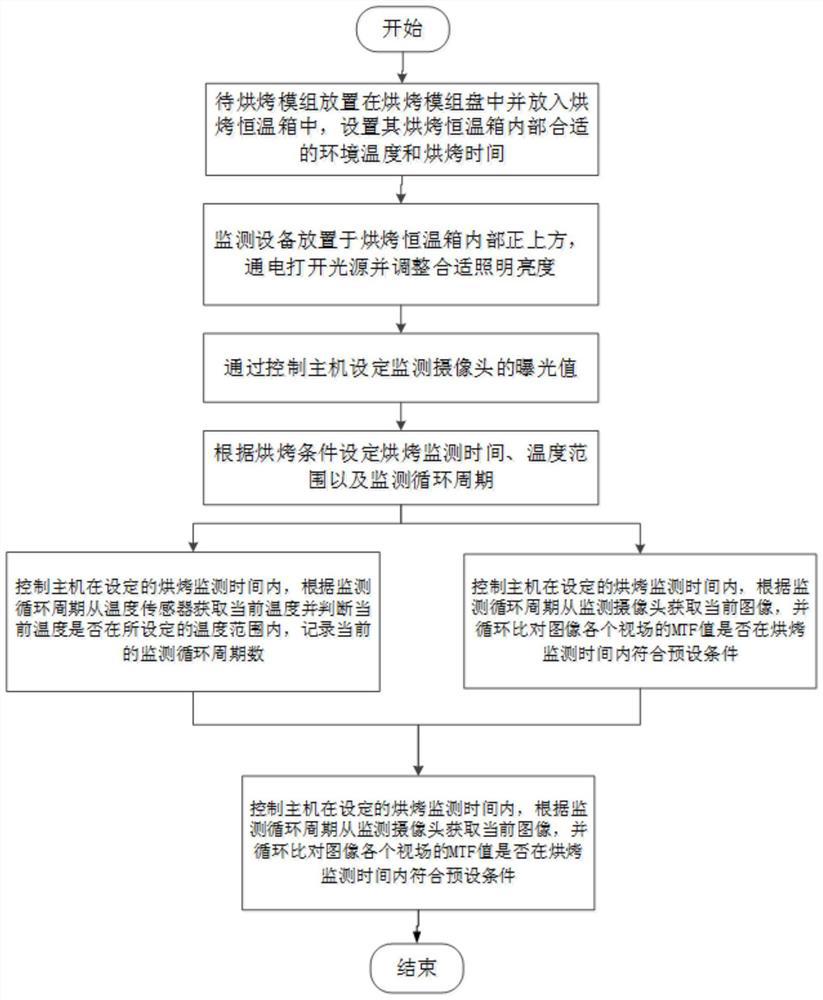

[0049] like figure 1 As shown, a monitoring method for camera module baking includes the following contents:

[0050] Preparation steps: place the camera module to be baked in the baking module tray, and put it into the baking incubator, set the baking conditions, and the baking conditions include the internal temperature of the baking incubator and the baking time; In this embodiment, settings are made according to actual conditions, for example, the internal ambient temperature is 40-80° C., and the baking time is 30-240 minutes.

[0051] Parameter setting steps: The monitoring equipment is located directly above the inside of the oven incubator, turn on the lighting source and adjust the appropriate lighting brightness; set the appropriate exposure value of the monitoring camera through the control host. The lighting brightness and exposure value can be adjusted according to the actual situation to ensure that the monitoring camera can obtain a clear image.

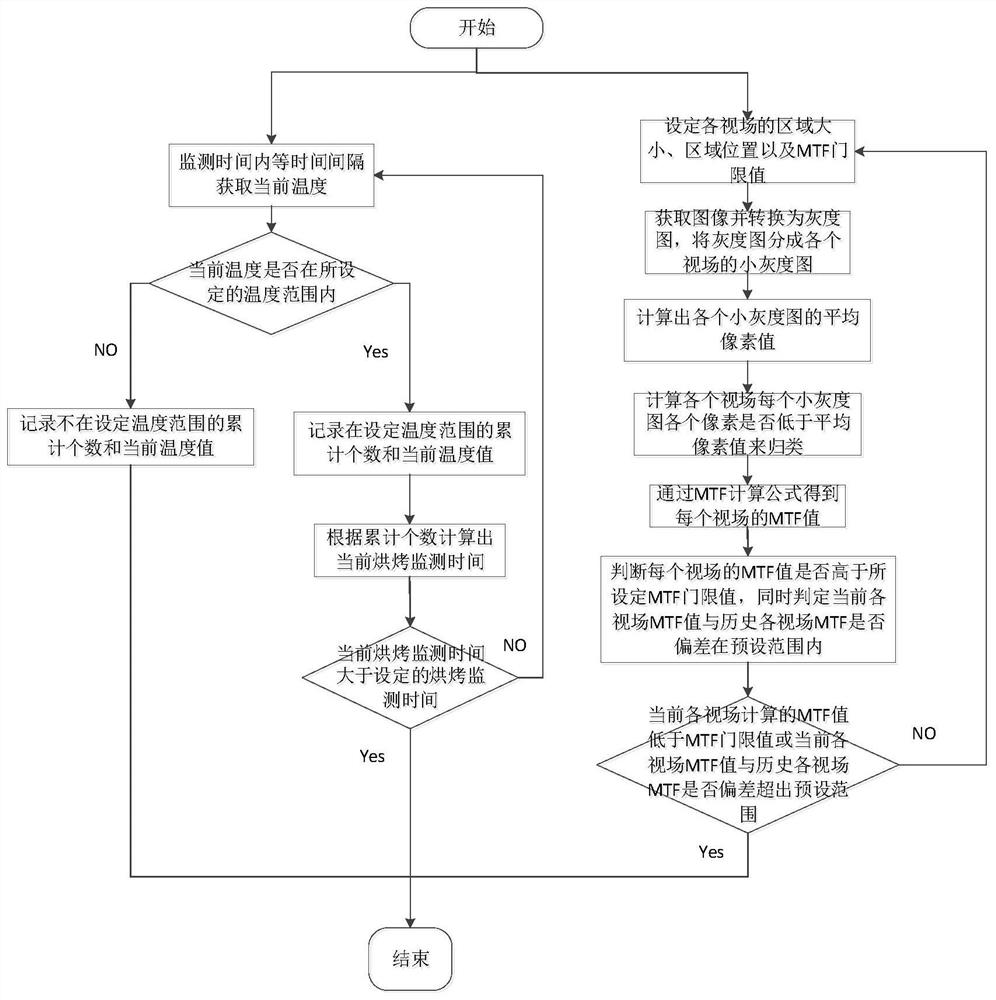

[0052]Set th...

Embodiment 2

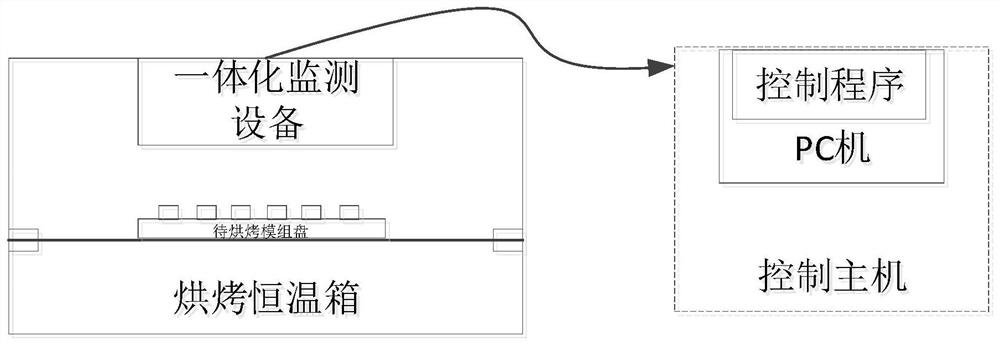

[0074] Based on the monitoring method for camera module baking, this embodiment also provides a monitoring system for camera module baking, such as image 3 As shown, it includes a baking incubator, a module tray to be baked for placing the camera module, and also includes monitoring equipment and a control host;

[0075] The inside of the baking incubator is used to place the module tray to be baked, and the baking incubator can set the baking temperature and baking time.

[0076] In this embodiment, the monitoring device adopts an integrated monitoring device, which is placed directly above the inside of the oven incubator, and includes a temperature sensor, an illumination light source and a monitoring camera. The temperature sensor is used to collect the current temperature; the illumination light source is used to provide illumination for the internal environment of the baking incubator; the monitoring camera is used to collect images inside the baking incubator.

[0077...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com