Automated production optimization technique for smart well completions using real-time nodal analysis

A technology of productivity and optimization algorithm, applied in design optimization/simulation, wellbore/well valve device, wellbore/well parts, etc., can solve problems such as troublesome process and few downhole valve adjustments, so as to improve sweep efficiency, Optimizing on-site testing requirements and good management effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

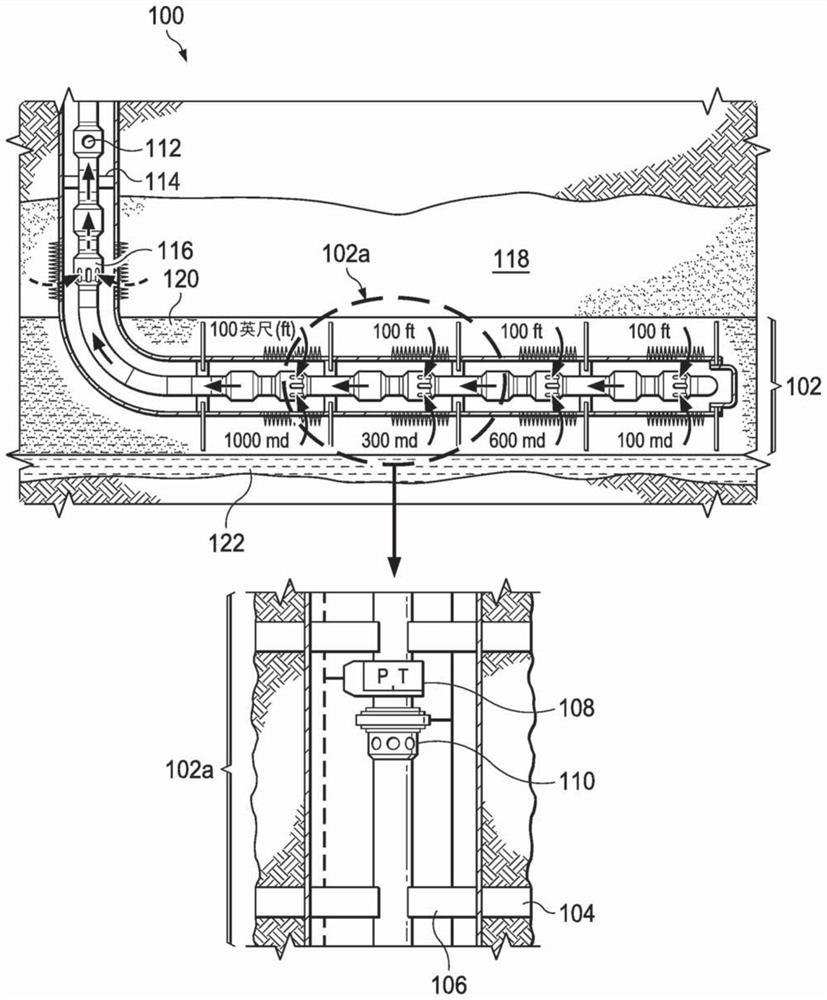

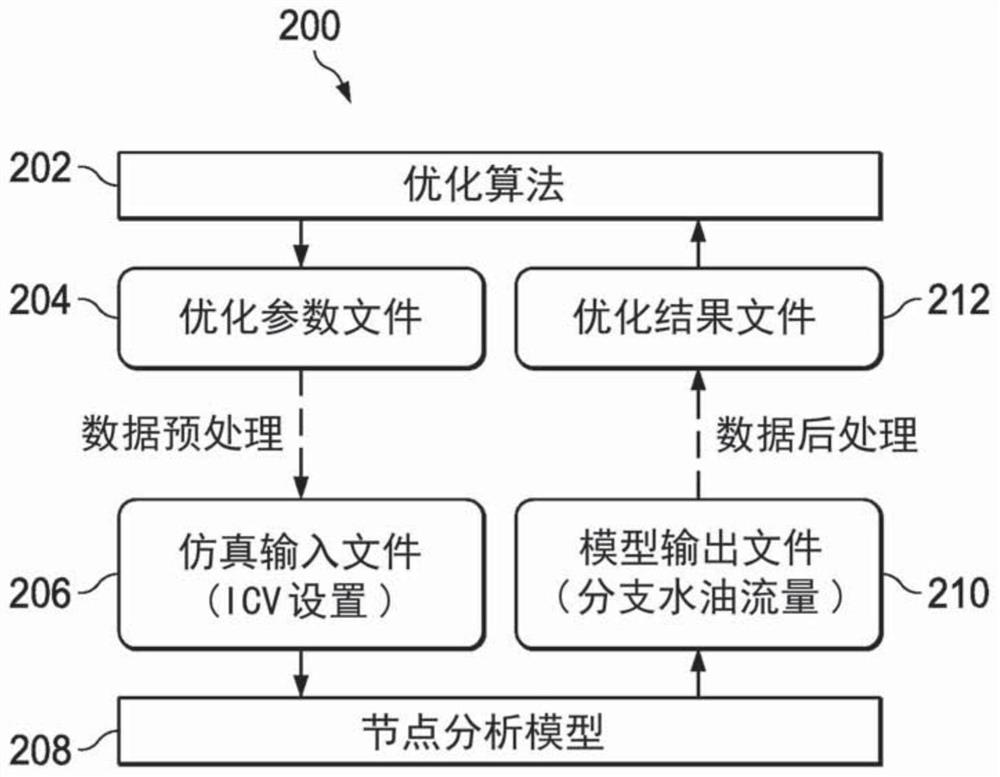

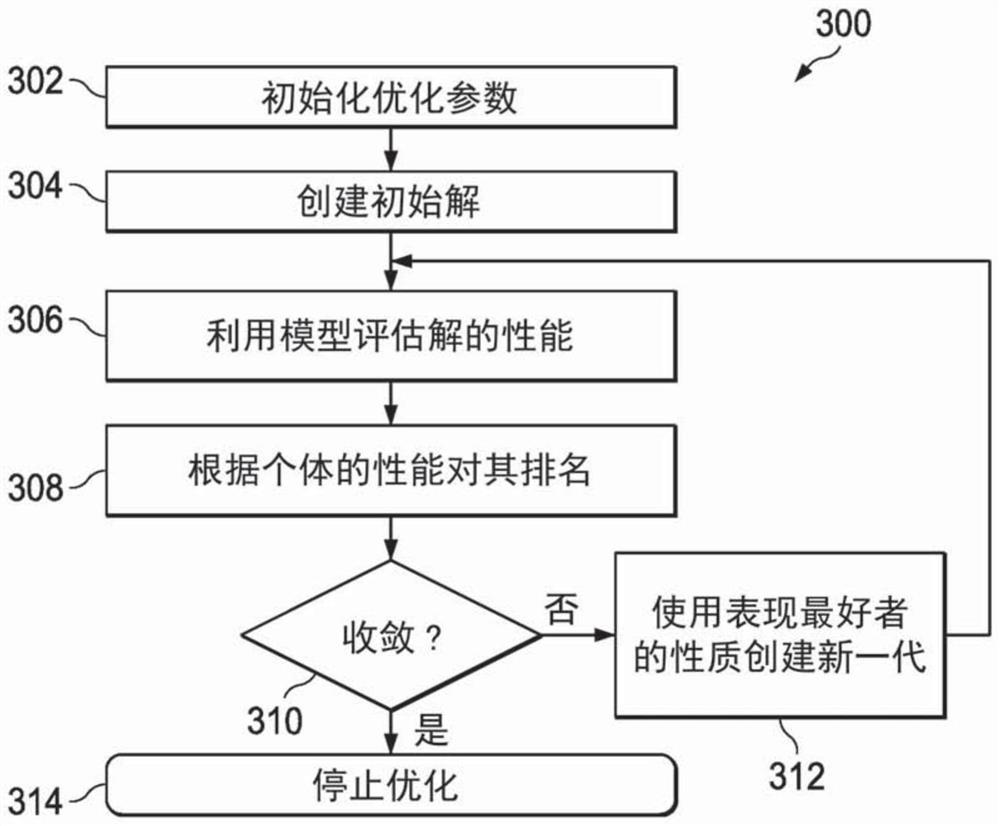

[0041] The following detailed description describes optimization techniques for smart well completions (SWC). For example, optimizing for a smart completion may refer to achieving well performance values that indicate or result in performance above a predetermined threshold. Various modifications, changes, and permutations to the disclosed embodiments may be made and will be apparent to those of ordinary skill in the art, and the general principles defined may be applied to other implementations without departing from the scope of the present disclosure. methods and applications. In some instances, details not necessary to gain an understanding of the described subject matter may be omitted so as not to obscure one or more of the described implementations with unnecessary detail, since such details are well within the skill of the art Within the skill of an ordinary skilled person. The disclosure is not intended to be limited to the described or illustrated embodiments but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com