Low-temperature high-pressure wall breaking equipment for production and processing of bee pollen freeze-dried powder

A low-temperature high-pressure, freeze-dried powder technology, used in mechanical equipment, grain processing, springs/shock absorbers, etc., can solve problems such as high vibration frequency, increased noise, and reduced stability of wall-breaking equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

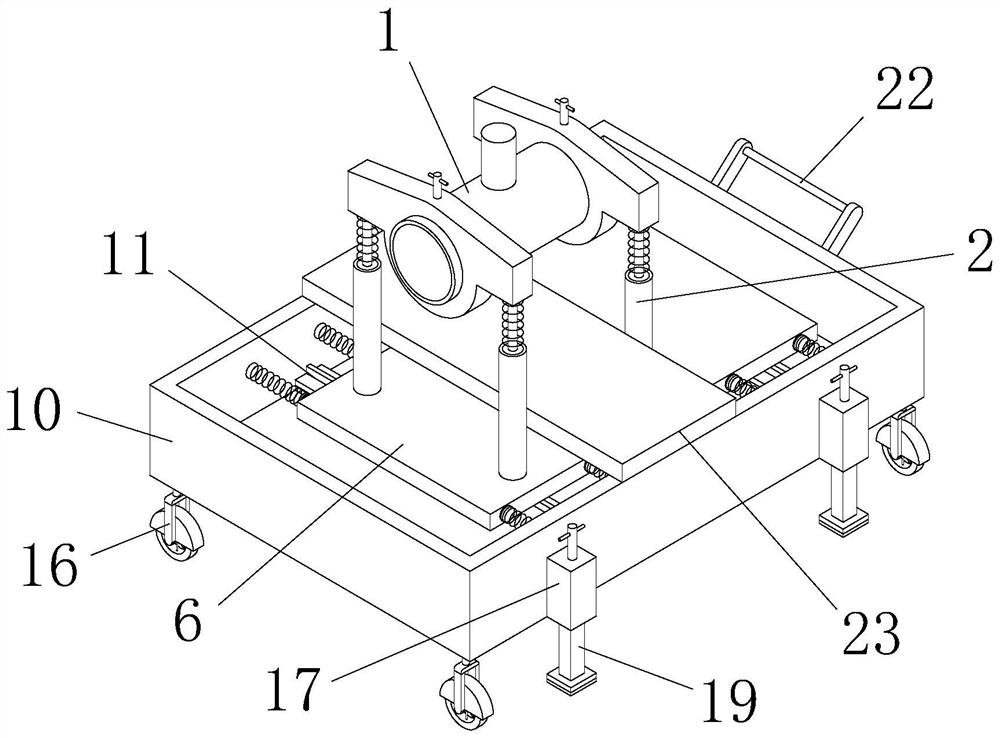

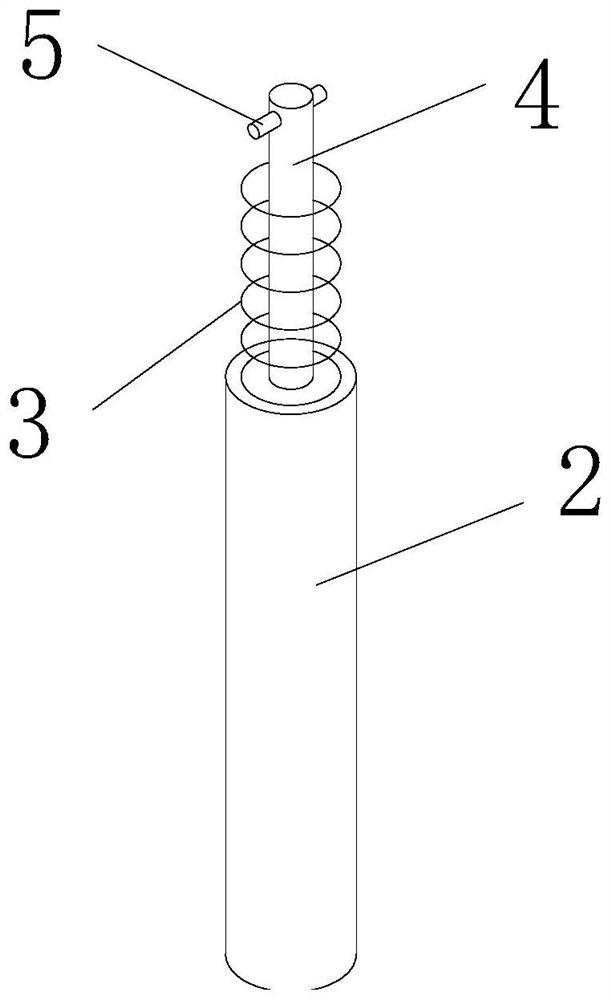

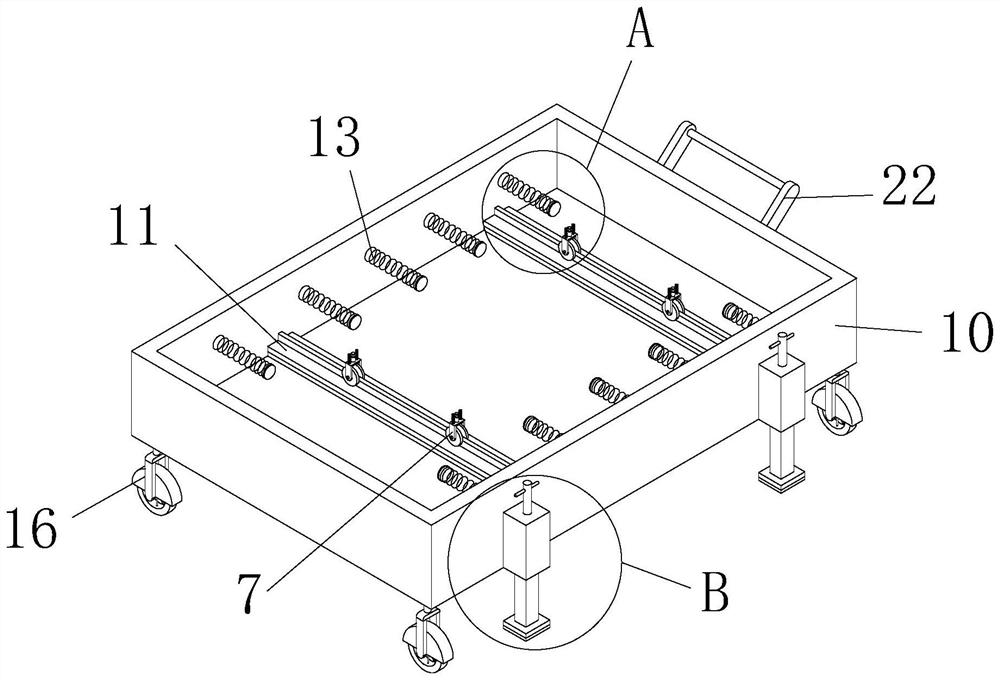

[0033] Embodiment: a kind of low-temperature high-pressure wall-breaking equipment for the production and processing of bee pollen freeze-dried powder, such as Figure 1-Figure 6 As shown, it includes a low-temperature, high-pressure wall-breaking machine body 1, four vibrating springs 3 are arranged at the bottom of the low-temperature, high-pressure wall-breaking machine body 1, and four support cylinders 2 are respectively fixedly connected to the bottom of the four vibration springs 3. The bottom of the machine body 1 is provided with four inserting rods 4, and the outer walls of the bottom ends of the four inserting rods 4 are respectively movably inserted into the top surfaces of the four supporting cylinders 2, and the bottom surfaces of the four supporting cylinders 2 are fixedly connected with a bottom plate 6, The bottom end of the bottom plate 6 is provided with four elastic displacement support wheels 7, and a base 10 is provided under the body 1 of the low-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com