Displayer back plate mounting mechanism

A technology of installation mechanism and display, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low work efficiency, time-consuming and laborious, low degree of automation, etc., and achieve high equipment utilization rate, high degree of automation, Produce fast-paced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the content of the present invention is not limited to the stated scope.

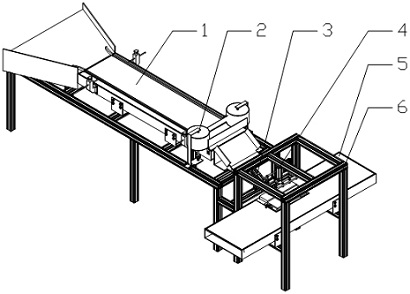

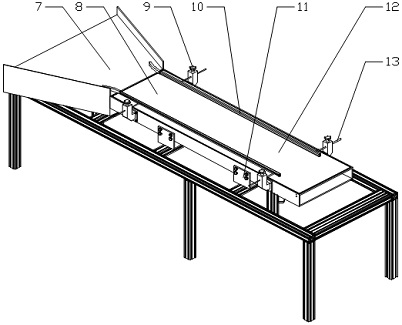

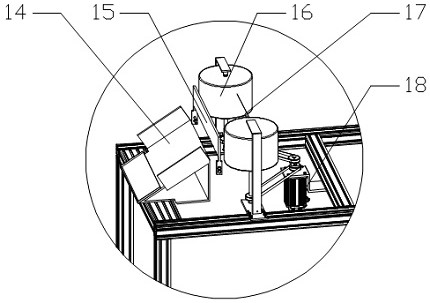

[0034] Such as figure 1 As shown, a display back panel installation mechanism includes a back panel feeding mechanism 1, a material distribution mechanism 2, a turning mechanism 3, a pressing mechanism 4, a display feeding mechanism 5 and an aluminum profile bracket 6, and the back panel feeding mechanism 1 passes T Type bolts are installed above the aluminum profile bracket 6, the material distributing mechanism 2 is located at the tail of the back plate feeding mechanism 1, the turning mechanism 3 is located on the right side of the material distributing mechanism 2, and the pressing mechanism 4 is located at the On the right side of the material distribution mechanism 2, above the display feeding mechanism 5, the display feeding mechanism 5 is fixed on the aluminum profile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com