New-flavor solid beverage uniform subpackaging process technology

A technology of solid beverage and process technology, which is applied in the direction of solid materials, packaging, transportation and packaging, etc. It can solve the problems of changing filling volume, solid beverage accumulation, and affecting filling accuracy, so as to improve filling accuracy and facilitate filling Quantity, easy to change the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

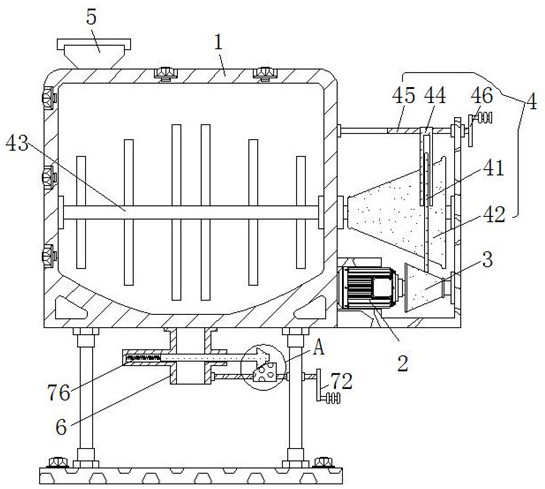

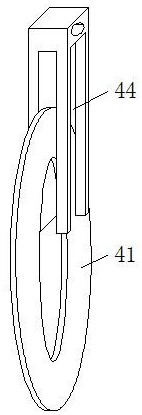

[0033] see Figure 1-2 , 5. A device for evenly distributing new-flavored solid beverages, comprising a speed regulating assembly 4, the inside of which is provided with a transmission disk 41, the outer wall of the bottom of the transmission disk 41 is in transmission connection with the top of the drive cone shaft 3, The internal transmission of the transmission disc 41 is connected with a driven cone shaft 42, the diameter of the right side of the driven cone shaft 42 is smaller than the diameter of its left side, and the inclination angle at the bottom of the driven cone shaft 42 is the same as the inclination angle at the top of the driving cone shaft 3 Similarly, the left side of the driven cone shaft 42 is fixedly connected with a stirring assembly 43, and the stirring assembly 43 is movably connected to the inside of the storage bin 1, and the outer wall of the transmission disk 41 top is sleeved with a cover plate 44, and the inside of the cover plate 44 top is A firs...

Embodiment 2

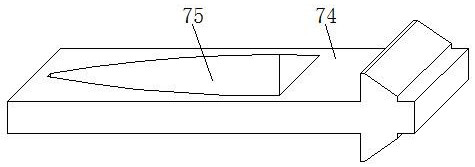

[0045] see figure 1 ,3 -5. A device for evenly distributing new-flavored solid beverages, including a discharge assembly 7, a second screw 71 is arranged inside the discharge assembly 7, and a second rotating handle 72 is welded on the right side of the second screw 71, The outer wall of the second screw mandrel 71 is threadedly connected with a trapezoidal block 73 , and the inside of the trapezoidal block 73 has threads that are compatible with the outer wall of the second screw mandrel 71 . The angle of inclination is the same, the left side of the top of the trapezoidal block 73 is slidably connected with a baffle plate 74, and the left side of the baffle plate 74 is slidably connected to the inside of the discharge pipe 6, and the inside of the baffle plate 74 is provided with a discharge port 75, the discharge port The diameter on the left side of 75 is less than the diameter on the right side, and the left side of baffle plate 74 is fixedly connected with support spring...

Embodiment 3

[0057] see Figure 1-5 , a new flavor solid beverage uniform packaging device, including a speed regulating assembly 4, the interior of the speed regulating assembly 4 is provided with a transmission disc 41, the outer wall of the bottom of the transmission disc 41 is connected to the top of the driving cone shaft 3 in transmission, and the transmission circle The internal transmission of the disk 41 is connected with a driven cone shaft 42, the diameter on the right side of the driven cone shaft 42 is smaller than the diameter on the left side, and the inclination angle at the bottom of the driven cone shaft 42 is the same as the inclination angle at the top of the driving cone shaft 3, The left side of the driven cone shaft 42 is fixedly connected with a stirring assembly 43, the stirring assembly 43 is movably connected inside the storage bin 1, the outer wall of the top of the transmission disc 41 is sleeved with a sleeve plate 44, and the internal screw connection at the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com