Uniform light-transmitting polypropylene composition as well as preparation method and application thereof

A polypropylene composition and polypropylene technology, applied in the field of modified plastics, can solve problems such as uneven light transmittance and haze, achieve uniform light transmittance or haze, and improve the uniformity of light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

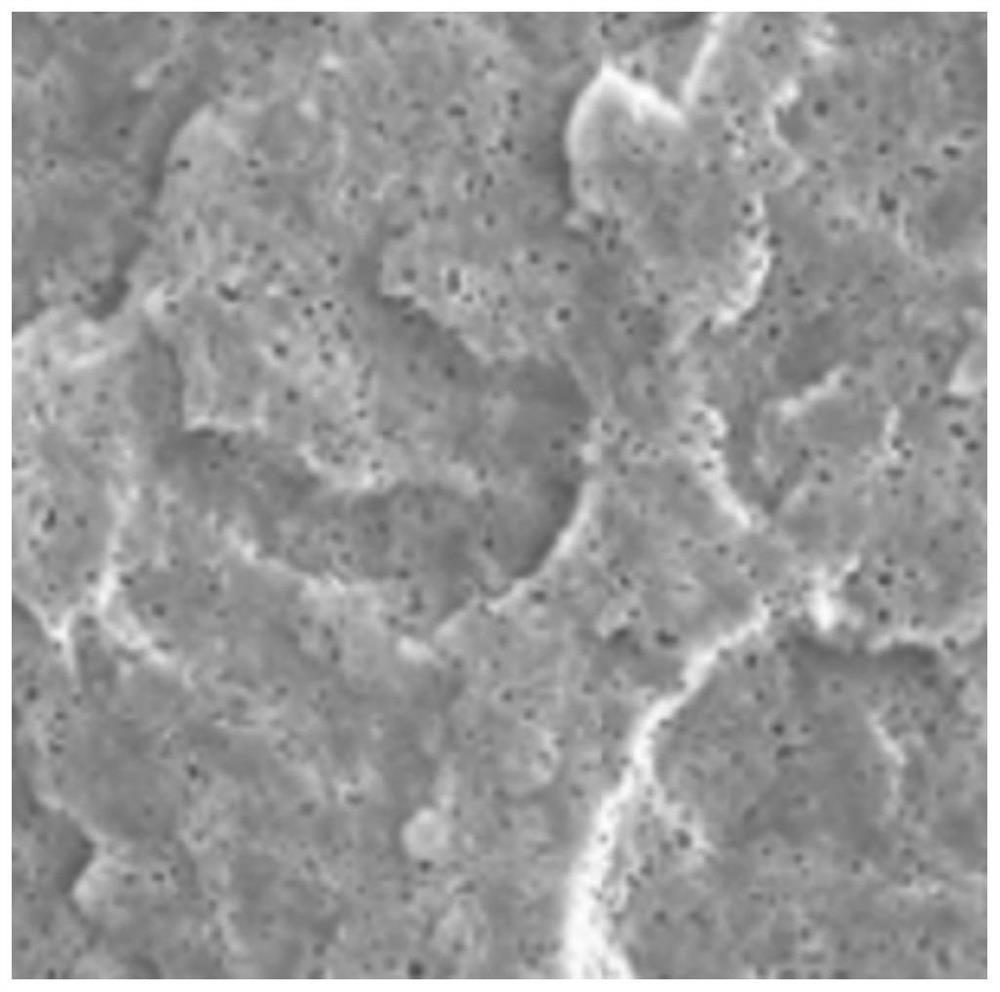

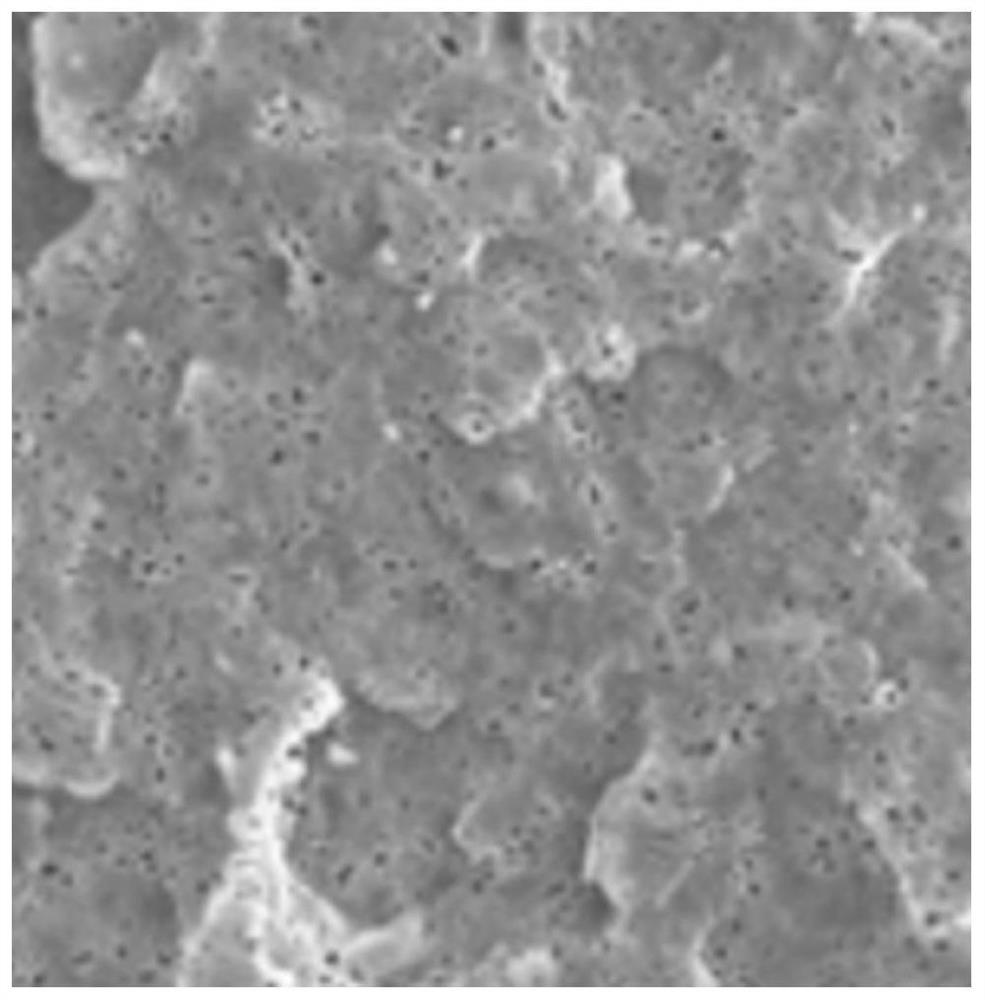

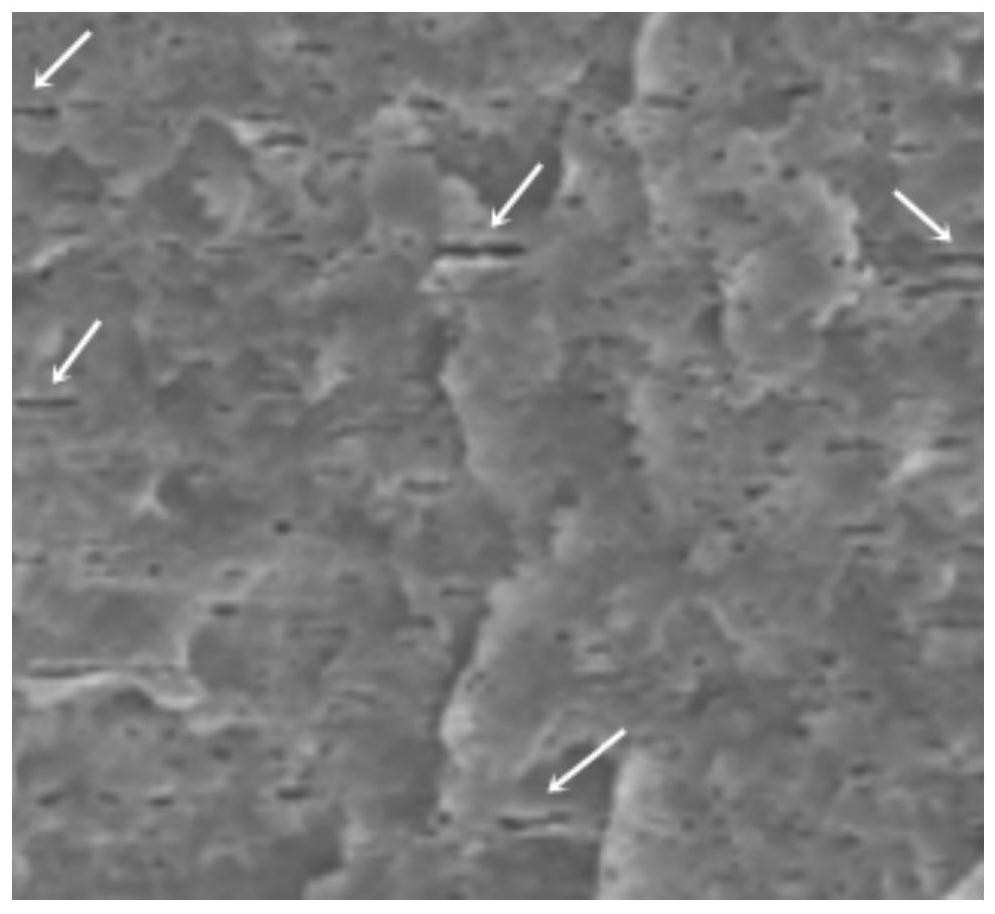

Image

Examples

Embodiment 1~18

[0067] Embodiments 1 to 18 provide a polypropylene composition, whose component contents are shown in Table 1, and the preparation method is as follows:

[0068] Mix the components according to Table 1, add them to a twin-screw extruder, melt blend, extrude and granulate to obtain a polypropylene composition, wherein the melt-blending temperature of the twin-screw extruder is 180-230°C .

[0069] The component content (weight part) of table 1 embodiment 1~18 polypropylene composition

[0070]

[0071]

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com