A fabrication method of a localized surface plasmon biochemical sensor

A biochemical sensor, plasma technology, applied in instruments, scientific instruments, biological testing, etc., can solve the problems of single micro-nano structure, small binding area, reduced detection efficiency and sensitivity, etc., to achieve easier combination, increase in number, and improve detection. Effects of Efficiency and Sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

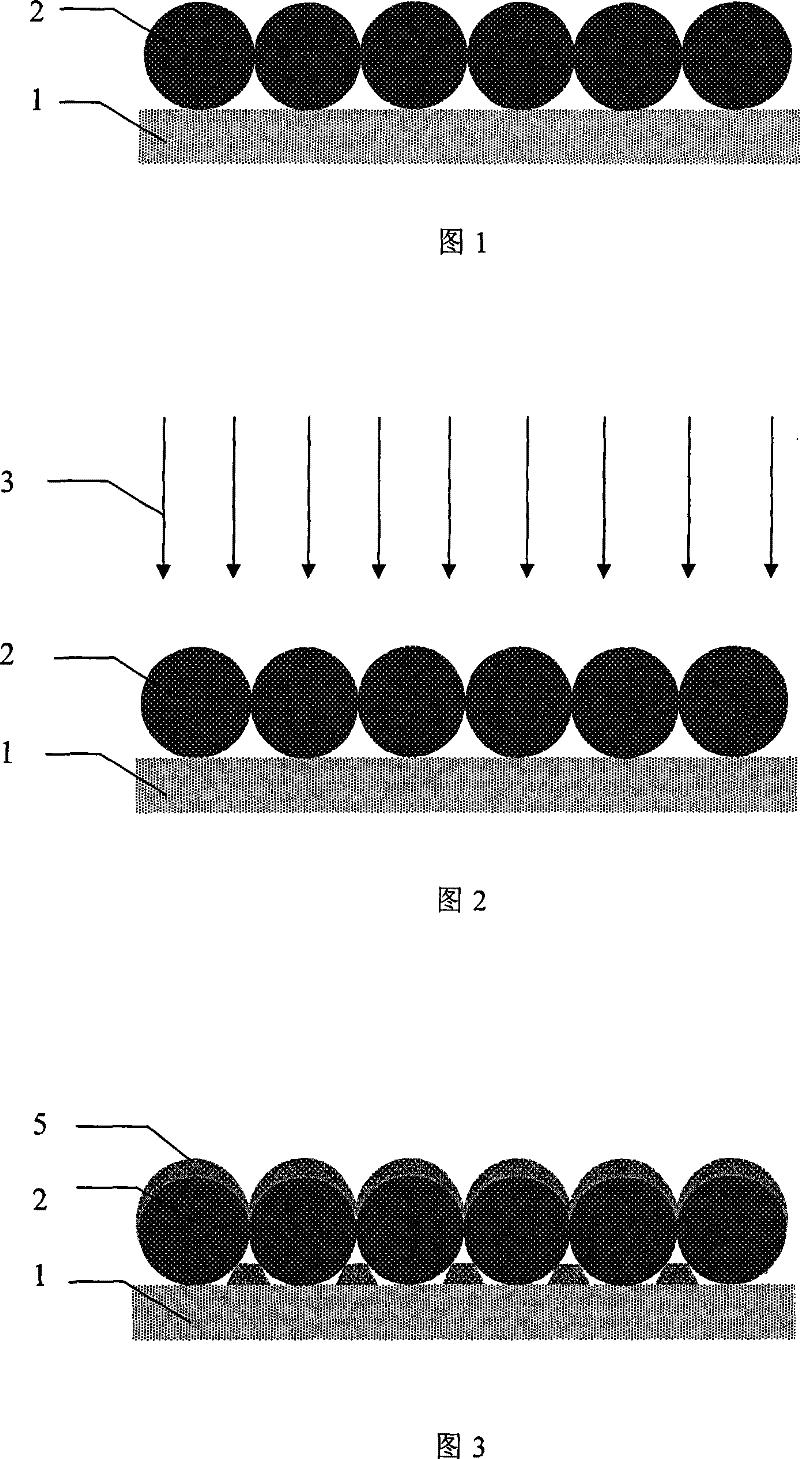

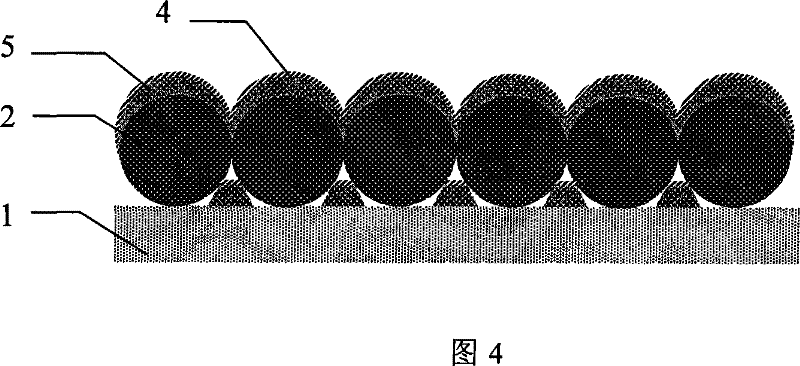

[0023] The present invention will be described in detail below with reference to specific embodiments and drawings, but the scope of protection of the present invention is not limited to the following embodiments, and should include all the content in the claims. Moreover, those skilled in the art can realize all the content in the claims from the following embodiment.

[0024] The specific process of the embodiment of the present invention is as follows:

[0025] (1) Select the substrate material according to the needs of the transmission wavelength, which can be visible light material glass, quartz, infrared material germanium, silicon, and clean the substrate with concentrated sulfuric acid and ammonia, and then dry it with nitrogen;

[0026] If the diameter of the nanospheres used in the production process can be compared with the wavelength of visible light, the transmission wavelength is within the range of visible light, and the substrate material can be glass, quartz, etc. If...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com