Ventilation equipment convenient to disassemble and assemble

A kind of ventilation equipment and convenient technology, which is used in the ventilation of mines/tunnels, mining equipment, and earth-moving drilling, etc. It can solve the problems of difficulty in disassembly and assembly of ventilation equipment, difficult to adjust the angle, etc., to broaden the scope of application and practicality, and to facilitate disassembly , Improve the effect of disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

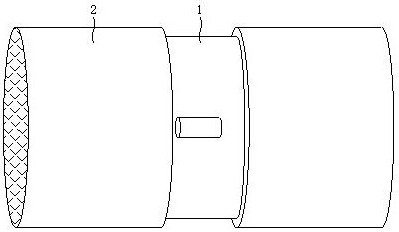

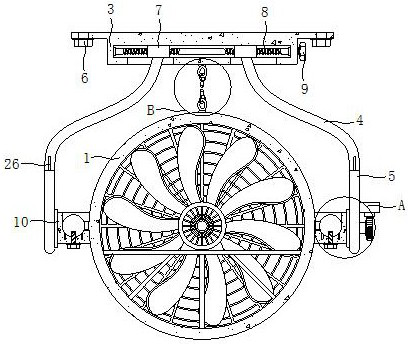

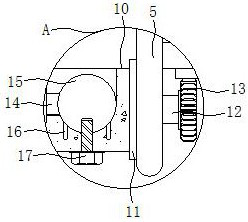

[0027] see Figure 1-5 , the present invention provides a technical solution: a convenient disassembly and assembly ventilation equipment, including a jet fan 1, a horizontal frame plate 3, a disassembly mechanism and an adjustment mechanism, the horizontal frame plate 3 is arranged on the top of the jet flow fan 1, and the horizontal frame plate The bottom of 3 is provided with two sets of vertical boards 5, and the vertical boards 5 are provided with connecting blocks 10, and the tops of the two groups of connecting blocks 10 are provided with T-shaped slots, and the front and rear side outer walls of the jet fan 1 are provided with positioning columns 15 for positioning. The column 15 is located in the T-shaped slot. The dismounting mechanism includes a slider 7, a two-way screw rod 8 and a hexagonal block 9 arranged on the horizontal frame plate 3. The dismounting mechanism can drive the two sets of connecting blocks 10 to move in the same direction or in the opposite direc...

Embodiment 2

[0032] see Figure 1-5 , on the basis of Embodiment 1, a positioning rod 16 is fixedly installed at the bottom of the positioning column 15, and the positioning rod 16 is clamped and installed in the positioning perforation. slot, the bottom of the connection block 10 is provided with a positioning bolt 17, the positioning bolt 17 passes through the opening and extends into the threaded groove, the connecting nut 6 on the horizontal frame plate 3 is screwed on the bolt at the pre-embedded position, and then the The horizontal frame plate 3 is installed, and then the jet fan 1 is hoisted between the two sets of vertical plates 5 under the horizontal frame plate 3, and then the hexagonal block 9 is twisted by holding the paste, and the hexagonal block 9 drives the rotation of the two-way screw rod 8 and drives Two groups of sliders 7 move in the same direction, and the two groups of sliders 7 drive two groups of connecting curved rods 4, two groups of vertical plates 5 and two g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com