Distance measurement compensation device

A compensating device and a technology for adjusting components, which is applied in the field of sights, and can solve problems such as inconvenient operation and carrying, and many scales on the adjustment cover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

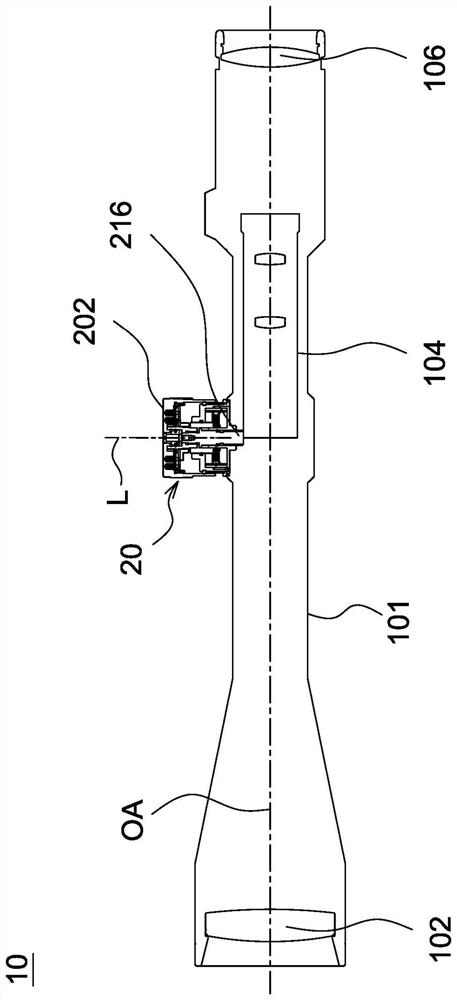

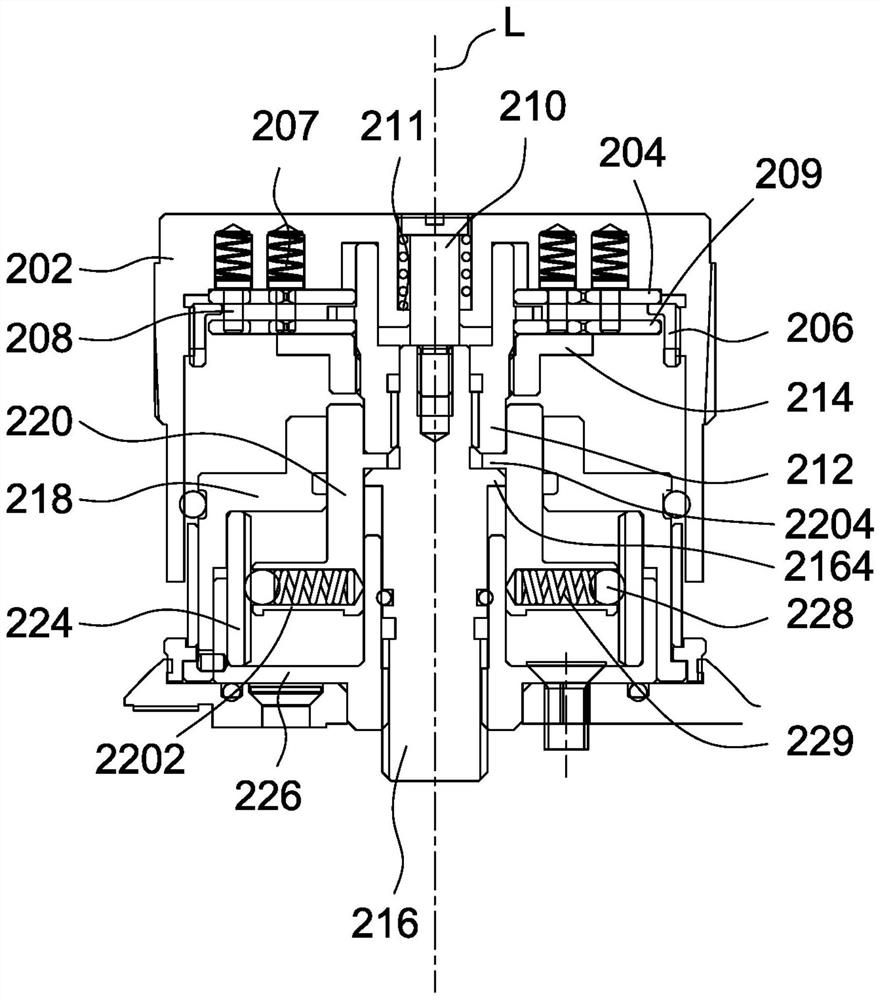

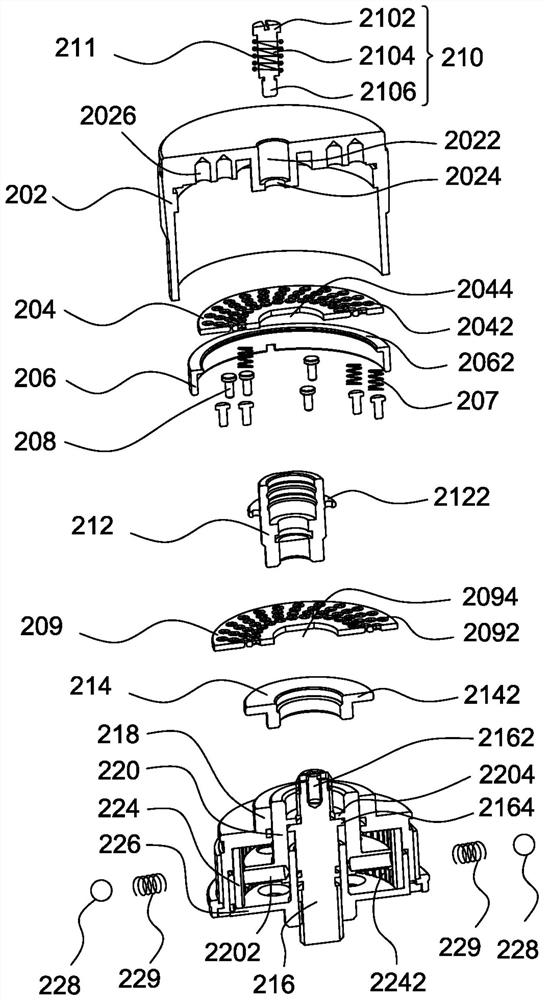

[0023] see figure 1 The distance measuring compensation device of the present invention is further a collimator 10 including a body 101, an objective lens group 102, an upright lens barrel 104, an eyepiece group 106 and a correction mechanism 20, wherein the objective lens group 102 and the eyepiece group 106 are respectively arranged on two sides of the body 101. end, and the erecting lens barrel 104 is disposed between the objective lens group 102 and the eyepiece lens group 106, so that the objective lens group 102, the erecting lens barrel 104, and the eyepiece lens group 106 are arranged in sequence along an optical axis OA. The correcting mechanism 20 is disposed on the main body 101 , and the adjusting component 216 of the correcting mechanism 20 abuts against the upright lens barrel 104 . To correct the impact, the user rotates the adjustment cover 202 of the correction mechanism 20 to move the adjustment assembly 216 along the axis L to correct the impact point. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com