Reciprocating type blank pressing device for rare earth permanent magnet production

A rare earth permanent magnet and pressing device technology, which is applied to the manufacturing of magnetic objects, magnetic materials, inductors/transformers/magnets, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

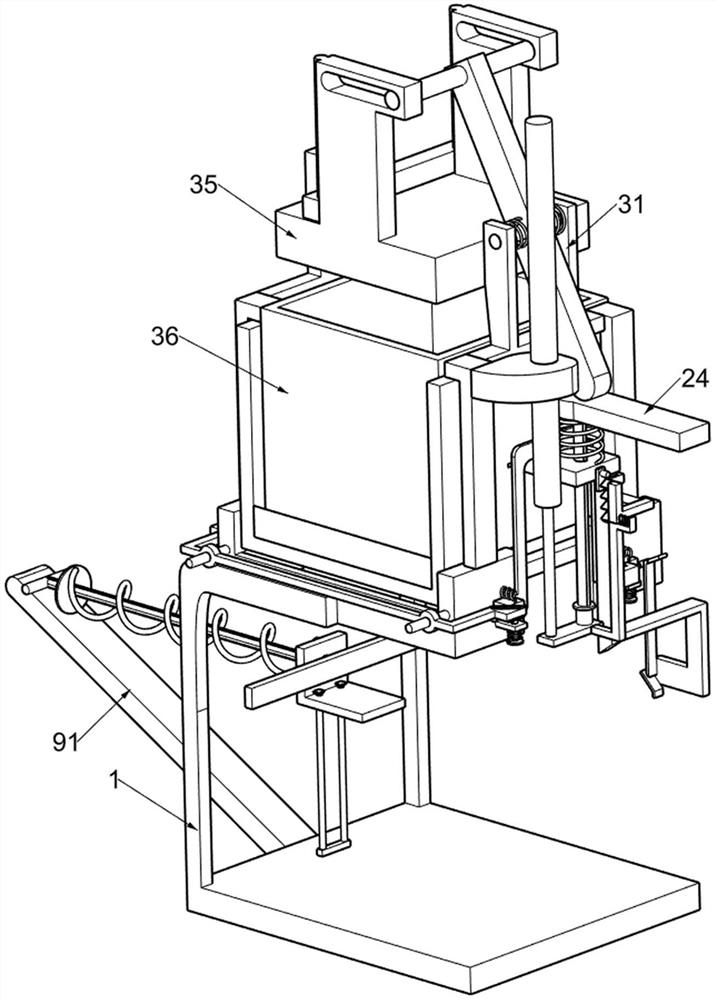

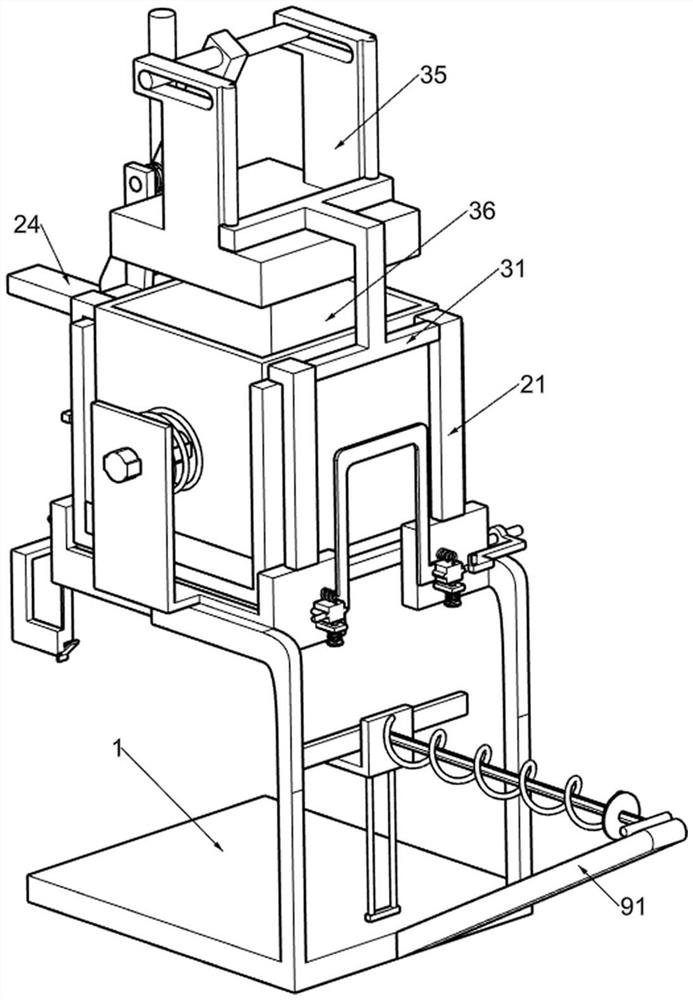

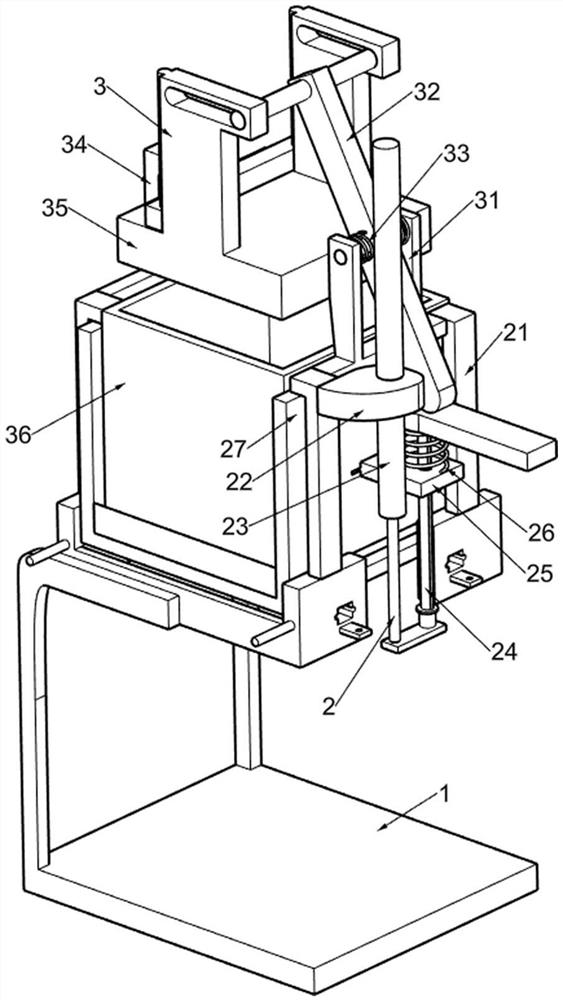

[0042] A reciprocating blank pressing device for rare earth permanent magnet production, such as Figure 1-5 As shown, it includes a first support frame 1, a push assembly 2 and a pressing assembly 3. The first support frame 1 is provided with a push assembly 2 for powering the equipment. A press-fit assembly 3 of a square rare-earth permanent magnet blank is synthesized.

[0043]The pushing assembly 2 includes a limit support frame 21, a rotating roller 2101, a first support plate 22, an electric push rod 23, a second support frame 24, a second support plate 25, a first spring 26 and a U-shaped pressing support plate 27, The top of the first support frame 1 is rectangular and distributed and connected with four limit support frames 21, the limit support frame 21 is L-shaped, and the limit support frame 21 is rotatably connected with a rotating roller 2101 for reducing friction, and the rotating roller 2101 It is cylindrical, and a first support plate 22 is connected to the o...

Embodiment 2

[0047] On the basis of Example 1, such as Figure 6-7 As shown, a vibrating assembly 4 is also included, and the vibrating assembly 4 used to make the rare earth raw material inside the limit frame 36 shake flat is arranged on the second support frame 24. The vibrating assembly 4 includes a fifth support frame 41, a sliding wedge Frame 42, the 3rd spring 43 and card column frame 44, the second support frame 24 is fixedly connected with the 5th support frame 41 away from limit frame 36 one side, the 5th support frame 41 top sliding type is connected with slide wedge-shaped frame 42, slides The wedge-shaped frame 42 is linearly distributed with inclined-plane rods near the limit frame 36, and the number of inclined-plane rods is at least four. The sliding wedge-shaped frame 42 is connected with the fifth support frame 41 for driving the sliding wedge-shaped frame 42 to reset. Three springs 43, one side of the outer wall of the U-shaped pressing support plate 27 are fixedly conne...

Embodiment 3

[0050] On the basis of Example 2, such as Figure 8-11 As shown, it also includes a switch assembly 5, the switch assembly 5 is arranged on the fifth support frame 41, the switch assembly 5 includes a guide frame 51, a swing plate 52 and a second torsion spring 53, the fifth support frame 41 is connected with a guide Frame 51, the bottom of guide frame 51 is inclined-plane structure, and the top of guide frame 51 is rotatably connected with swing plate 52, and is connected with the second torsion spring 53 for driving swing plate 52 to reset between swing plate 52 and guide frame 51.

[0051] Also includes a support assembly 6, the support assembly 6 is located on the first support frame 1, and the support assembly 6 includes a support block 61, a fourth spring 62, a limit card frame 63, a fifth spring 64, and a U-shaped connecting plate 65 , clamp bar 66 and sliding slotted frame 67, rectangular distribution sliding type is connected with four support blocks 61 on the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com