Foldable diatom mud groove automatic glue filling machine

A diatom mud and folding technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of unsightly sizing amount, uneven glue line, easy fatigue, etc., and achieve the accuracy of gluing. , Improve the effect of glue filling, improve the effect of glue filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

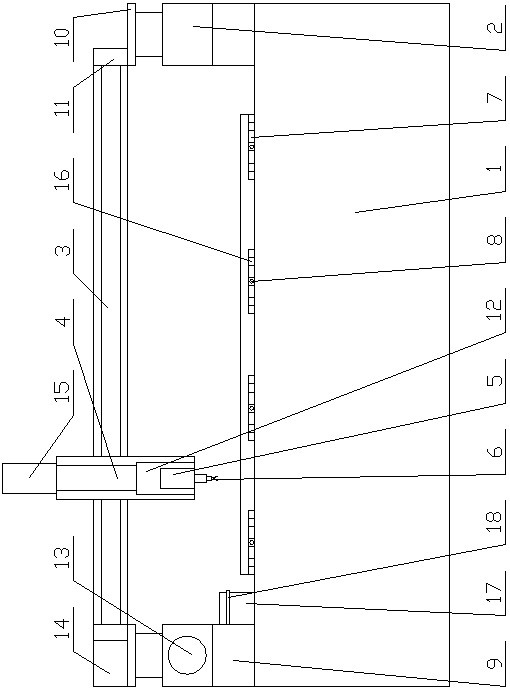

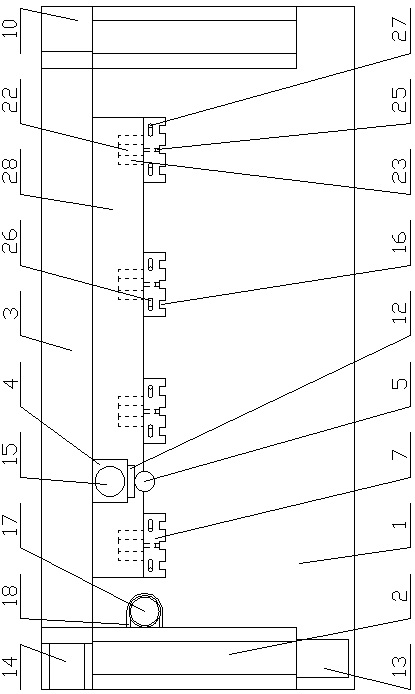

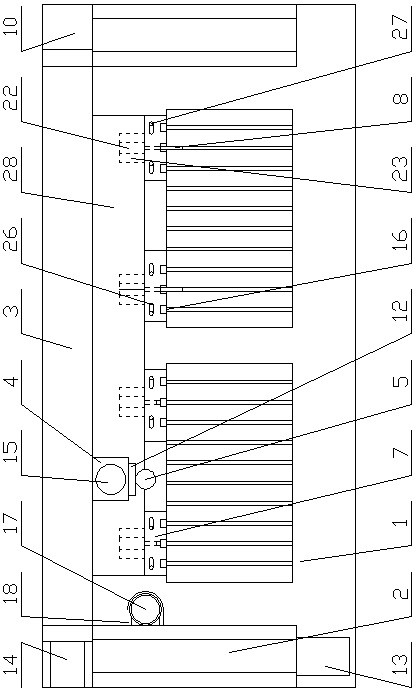

[0039] combine Figure 1~Figure 6 It can be seen that the groove automatic glue repairing machine for the folding diatom mud foot pad of the present invention includes a machine 1, the top surface of the machine 1 is horizontal, and the top surface of the machine 1 is provided along the front and rear directions. The horizontal reciprocating beam track 3, the two ends of the beam track 3 are respectively moved along the longitudinal track 2 fixed on the top surface of the machine table 1 by the driving device A13, and the longitudinal track 2 is along the direction perpendicular to the beam track 3 Arrangement, the beam track 3 is provided with a lift rail 4 that horizontally reciprocates along the beam track by the drive device B14, and the lift track 4 is provided with a glue spray head that moves up and down in the vertical direction by the drive device C15 6. There are two glue spraying ports 21 at the bottom of the glue spraying head 6. The glue spraying ports 21 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com