Gear transmission structure of tracked robot

A technology of gear transmission and robotics, which is applied to motor vehicles, crawler vehicles, transportation and packaging, etc., can solve the problems of inconvenient fixed diameter of the front gear, and achieve the effects of improving field survivability and continuous operation ability, improving efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

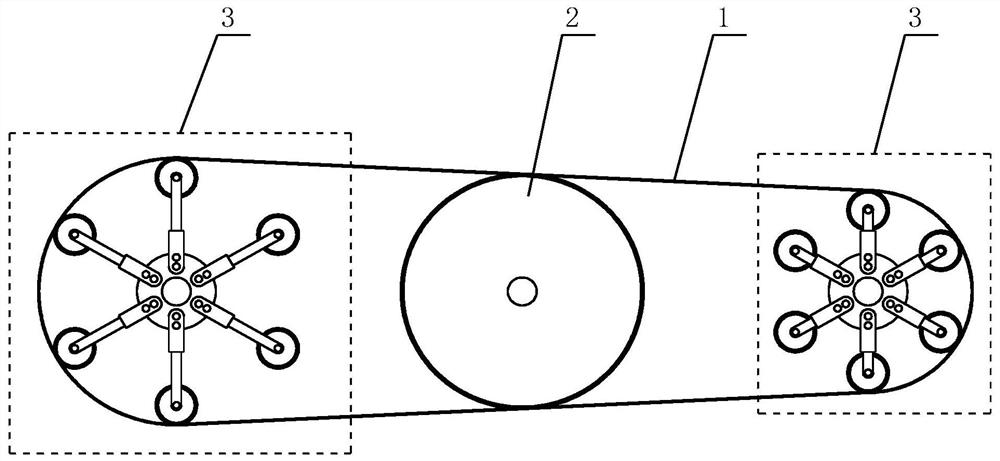

[0018] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a crawler robot gear transmission structure described in this embodiment, which includes a crawler belt 1; this embodiment also includes an intermediate transition gear 2 and two reducing gear mechanisms 3; the intermediate transition gear 2 is arranged on two Between the reducing gear mechanisms 3 , the crawler belt 1 is sleeved on the intermediate transition gear 2 and the two reducing gear mechanisms 3 .

specific Embodiment approach 2

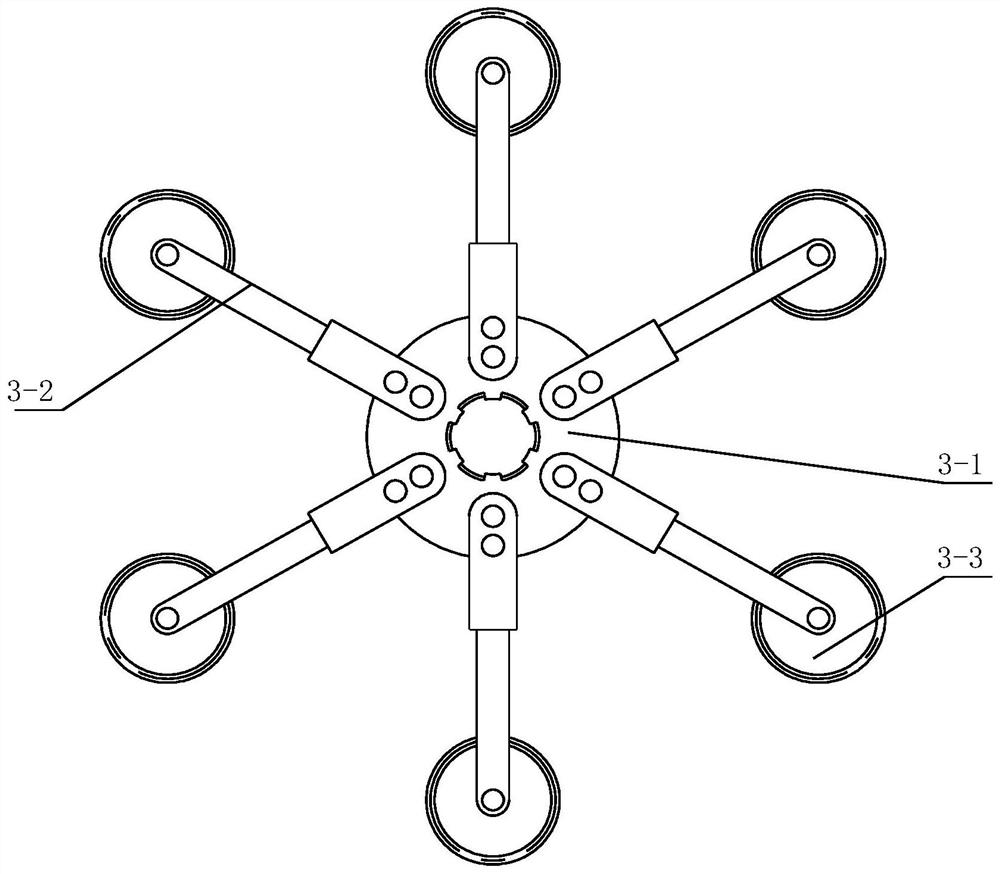

[0019] Specific implementation mode two: combination Figure 1 to Figure 4 To illustrate this embodiment, the reducing gear mechanism 3 of a crawler robot gear transmission structure described in this embodiment includes a wheel disc 3-1, six electrohydraulic cylinder assemblies 3-2 and six fixed gear assemblies 3-3; Six electro-hydraulic cylinder assemblies 3-2 are evenly arranged on the edge of the wheel disc 3-1 along the circumferential direction, and one end of each electro-hydraulic cylinder 3-2 is fixedly connected with the wheel disc 3-1, and each electro-hydraulic cylinder 3- The other end of 2 is fixedly connected with a fixed gear assembly 3-3. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

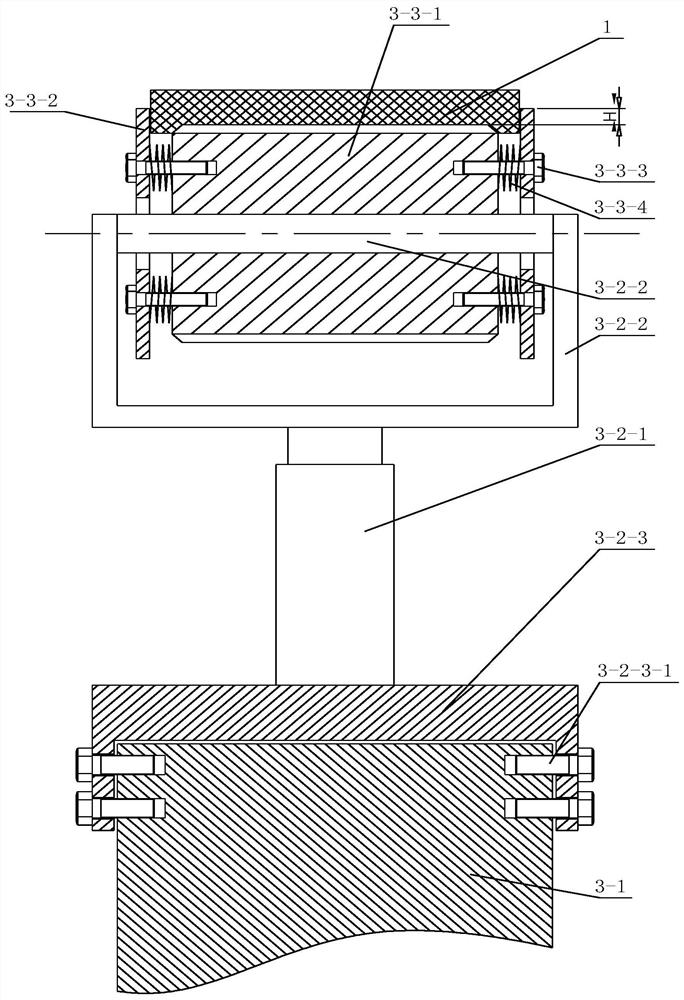

[0020] Specific implementation mode three: combination Figure 1 to Figure 4 To illustrate this embodiment, each electric hydraulic cylinder assembly 3-2 of a crawler robot gear transmission structure described in this embodiment includes an electric hydraulic cylinder 3-2-1, an outer frame 3-2-2 and an inner frame 3-2-3; the cylinder body of the electric hydraulic cylinder 3-2-1 is fixedly connected with the inner frame 3-2-3, and the piston rod of the electric hydraulic cylinder 3-2-1 is fixed with the outer frame 3-2-2 connection, the inner insert frame 3-2-3 is fixedly connected with the wheel disc 3-1, and the outer insert frame 3-2-2 is fixedly connected with the fixed gear assembly 3-3. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com