Cargo hold cover for large ship

A cargo hold and marine technology, applied in the field of large marine cargo hatch covers, to reduce the probability of damage and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

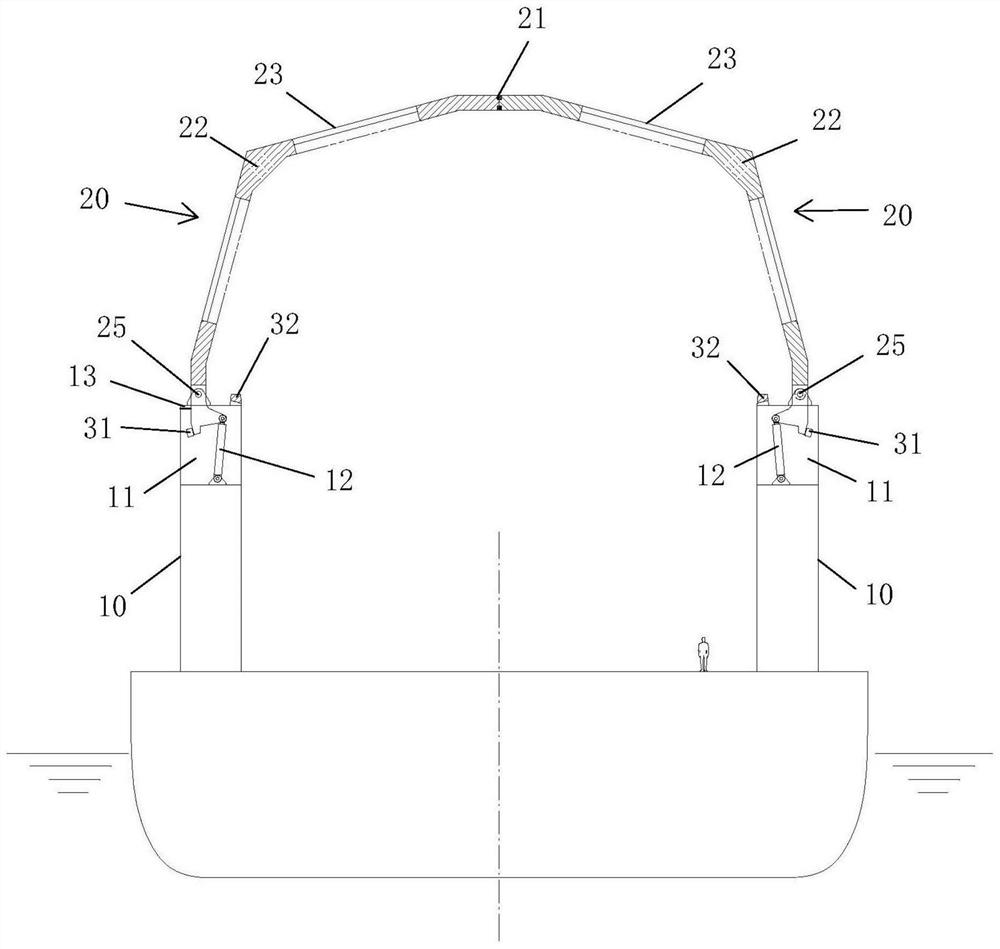

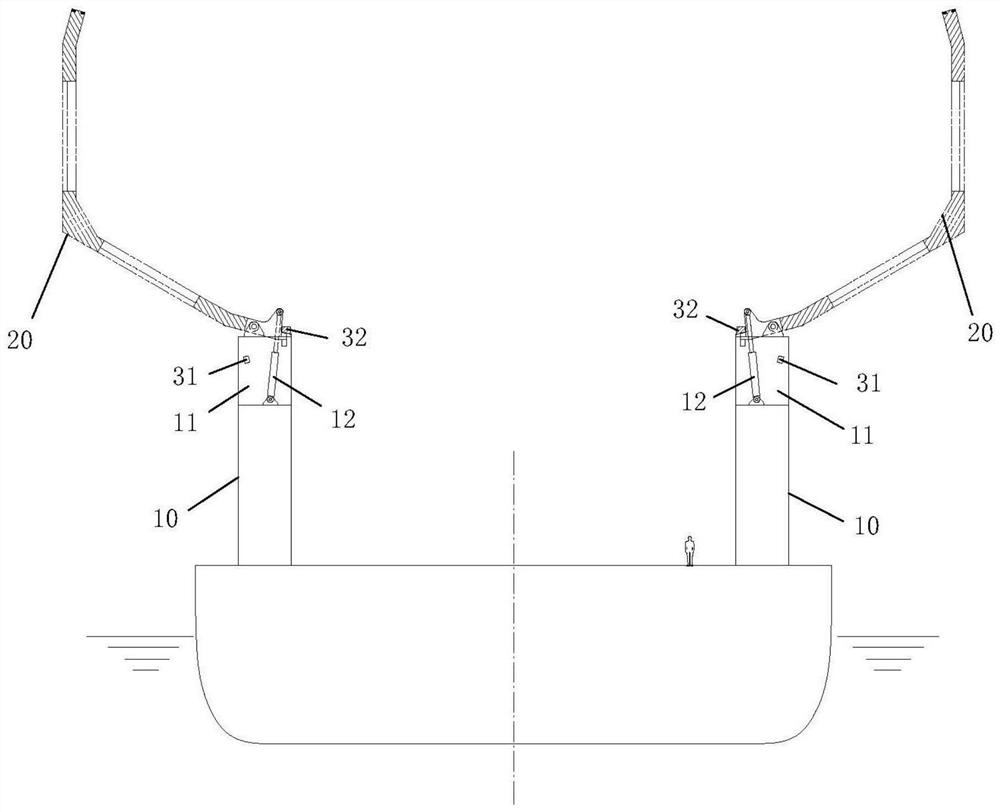

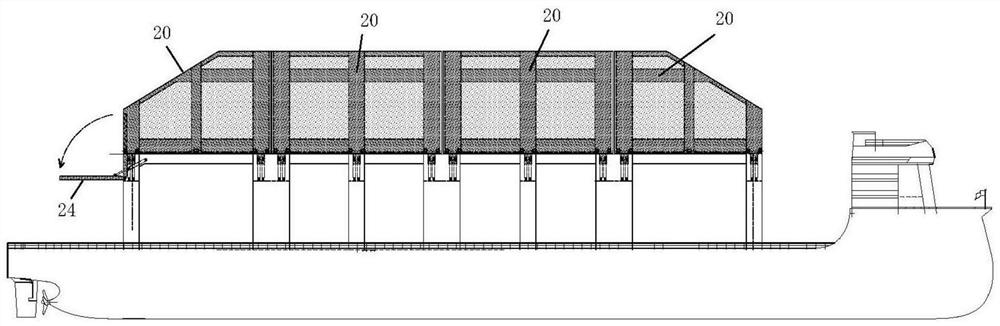

[0020] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0021] like figure 1 and figure 2 As shown, a large-scale marine cargo hatch cover is located on the cargo compartment wall 10; it includes two cover plates 20 that can be opened to the port and starboard outward directions respectively, and the upper ends of the two cover plates 20 abut against each other. The cover plate 20 is distributed obliquely from the upper end to the lower end.

[0022] After the two cover plates are connected, it is the highest at the joint of the two cover plates, and gradually decreases from the joint of the two cover plates to both sides. This prevents rain or seawater from accumulating on the cover.

[0023] A sealing member 21 is provided between the upper ends of the two cover plates 20 . The material of the sealing member is rubber.

[0024] A locking device (not shown...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap