On-site detection device for compaction degree of roadbed layer of highway engineering

A technology for on-site testing and engineering roads, which is applied in the field of foundation soil surveying, sampling devices, infrastructure engineering, etc., can solve the problems of ring knife tilt, high compaction, and the inability to guarantee the accuracy of test results, etc., to increase the accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

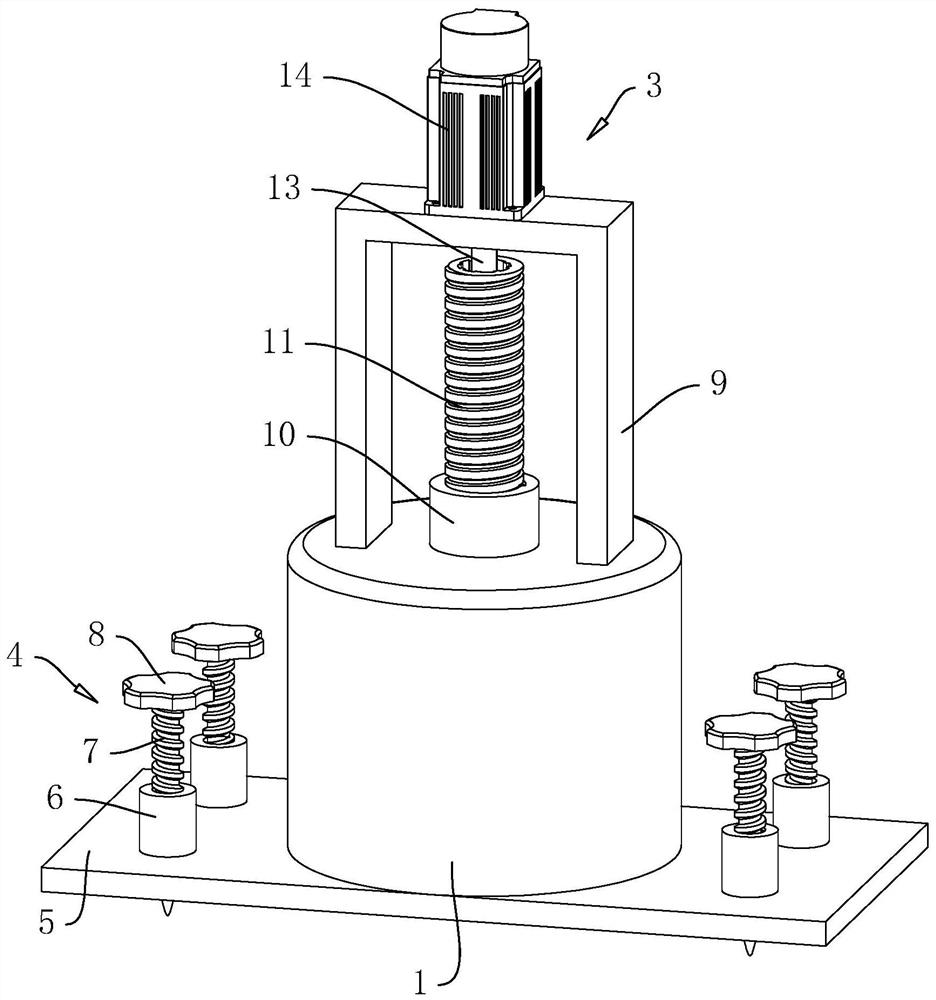

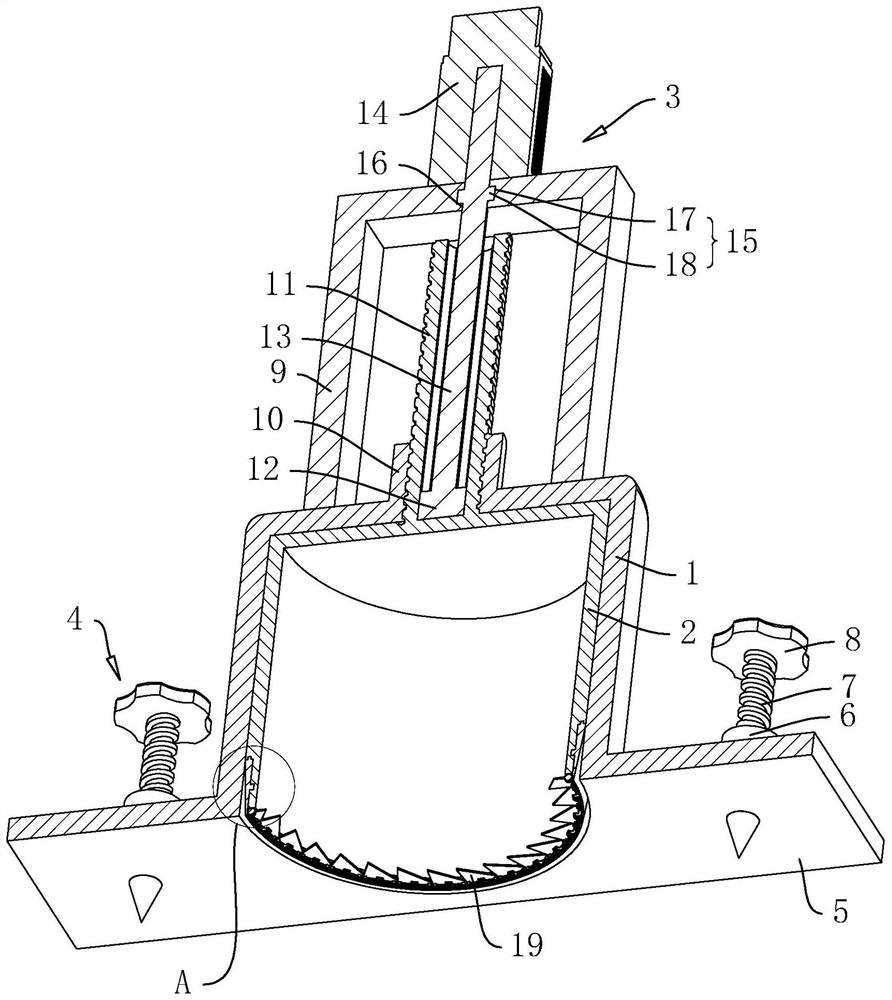

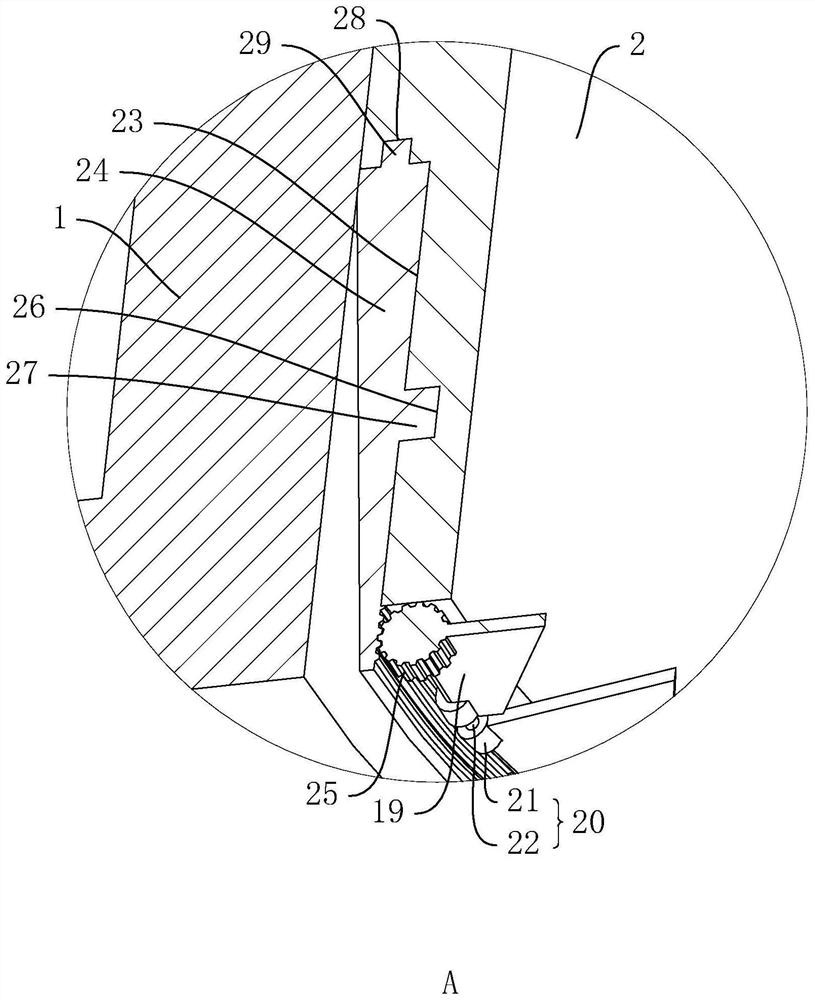

[0024] The following is attached Figure 1-3 The application is described in further detail.

[0025] The embodiment of the present application discloses an on-site detection device for the degree of compaction of a road base of a highway project. refer to figure 1 and figure 2 , an on-site detection device for road base compaction in highway engineering comprises a fixed sleeve 1, a sampling sleeve 2, a driving mechanism 3 and a fixing mechanism 4, wherein the fixing sleeve 1 and the sampling sleeve 2 are both cylindrical and the bottom is The opening is set, the sampling sleeve 2 is slidably connected to the inside of the fixed sleeve 1, and the outer walls on both sides of the fixed sleeve 1 are respectively fixedly connected with support plates 5 arranged horizontally, and the fixing mechanism 4 is arranged on the support plate 5 for limiting The relative position between the fixed sleeve 1 and the ground is fixed, and the driving mechanism 3 is arranged on the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com