Temperature measuring method and temperature measuring device for constant temperature area of vertical oxidation furnace

A technology of temperature measurement and oxidation furnace, which is applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of temperature reaching the preset value, failure to verify the uniformity of furnace temperature, and large spacing between layouts, etc., to improve temperature uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

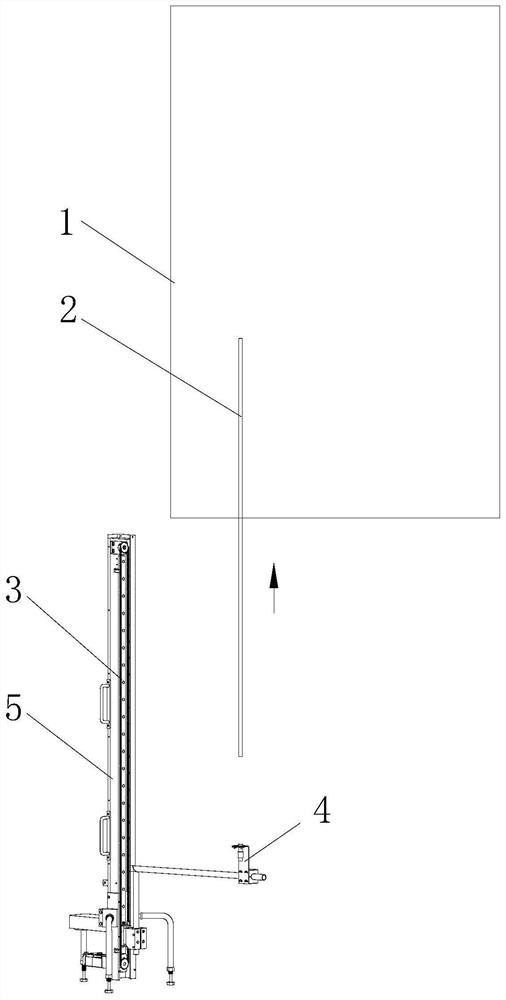

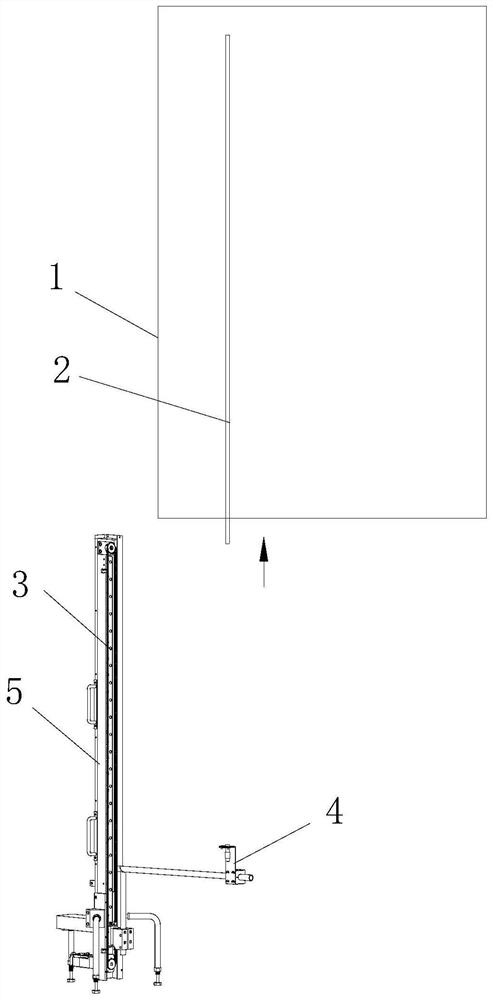

[0031] Such as Figure 1 to Figure 4 As shown, in the temperature measurement method used in the constant temperature zone of the vertical oxidation furnace in this embodiment, a thermocouple perforation is reserved at the bottom of the oxidation furnace 1, and the temperature measurement method includes the following steps:

[0032] S1, the thermocouple 2 is extended into the furnace from the thermocouple perforation at the bottom of the oxidation furnace 1, as figure 1 shown, and move up vertically so that the top of thermocouple 2 is close to the top of the furnace, and the bottom of thermocouple 2 is outside the furnace, as figure 2 shown;

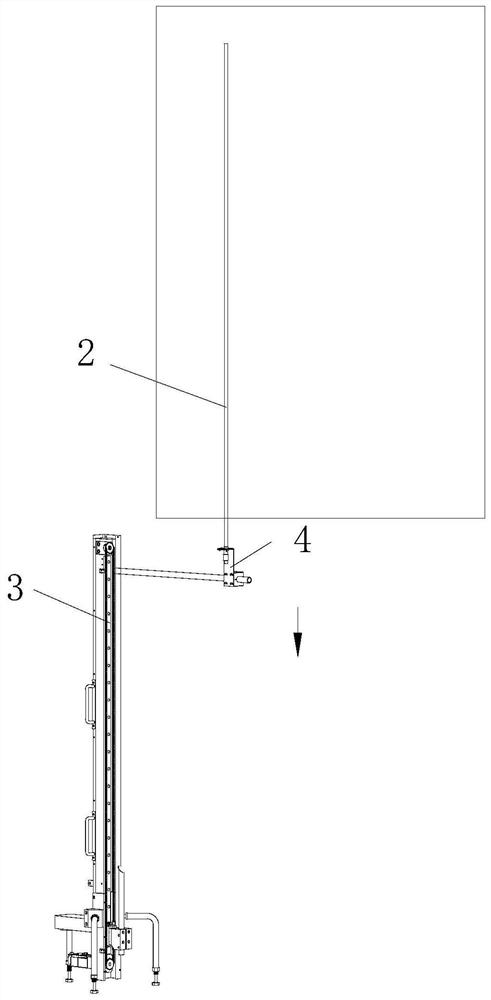

[0033] S2. Raise the thermocouple seat 4 on the lifting mechanism 3 below the oxidation furnace 1 to the upper limit position, and then install the bottom of the thermocouple 2 on the therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com