Ship safe harbor returning cable and manufacturing method thereof

A manufacturing method and safe technology, applied in the direction of cable/conductor manufacturing, insulated cable, power cable with shielding layer/conductive layer, etc., can solve the problem of no cable, etc., and achieve the effect of overcoming the low temperature resistance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the embodiments, so that those skilled in the art can easily understand the present invention.

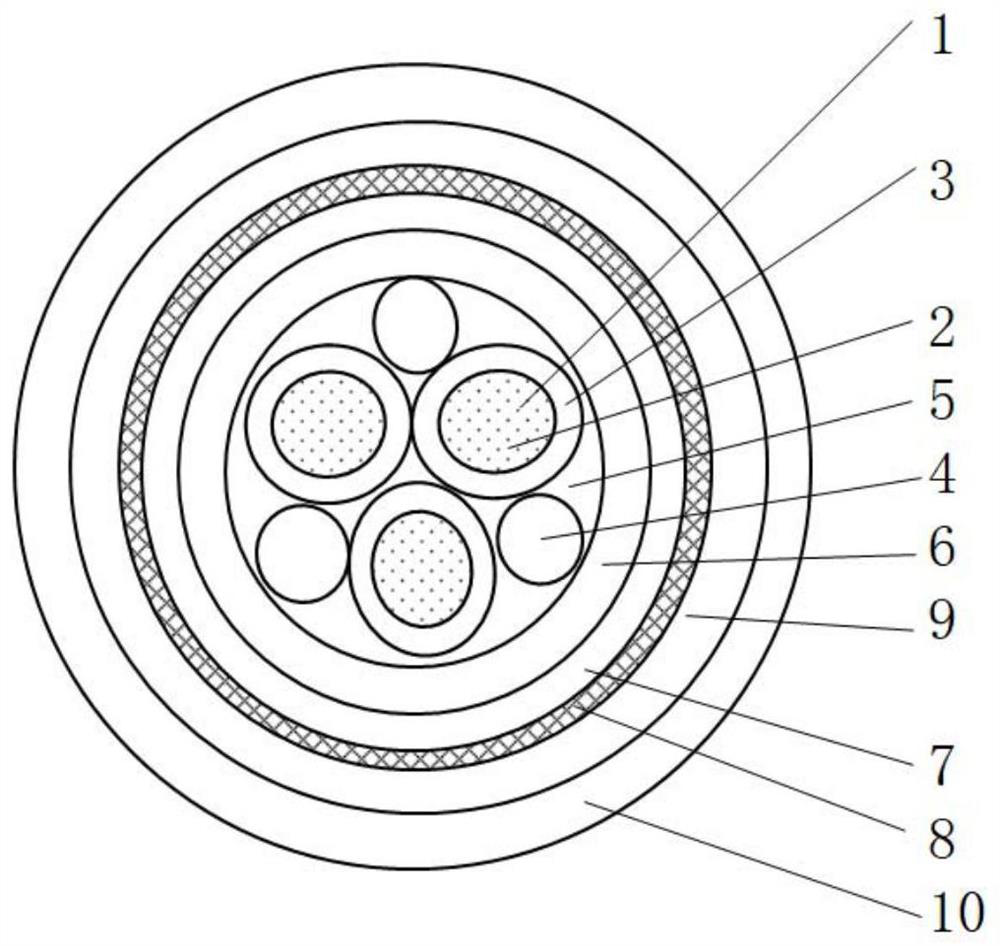

[0021] Such as figure 1 As shown, a cable for safe return of a ship to port includes an insulated core. The insulated core includes a conductor 1 and an insulating layer 3. The conductor 1 is formed by twisting a plurality of metal-plated annealed copper wire monofilaments. The gap between the copper wires is It is filled with conductor sealant 2; a plurality of insulated cores and sealant filling strips 4 constitute a cable core, and the gap between the insulated cores and the sealant filling strips is filled with a soft-melt core sealant 5; The outer layer of the cable core is sequentially provided with a first wrapping tape 6 , an inner liner 7 , an armor 8 , a second wrapping tape 9 , and an outer sheath 10 to form the entire cable.

[0022] The conductor 1 adopts metal-plated annealed stranded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com