Stator leading-out wire structure of air internal-cooling generator

A generator stator, air cooling technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of large current, hidden safety hazards, limited basic space of generators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

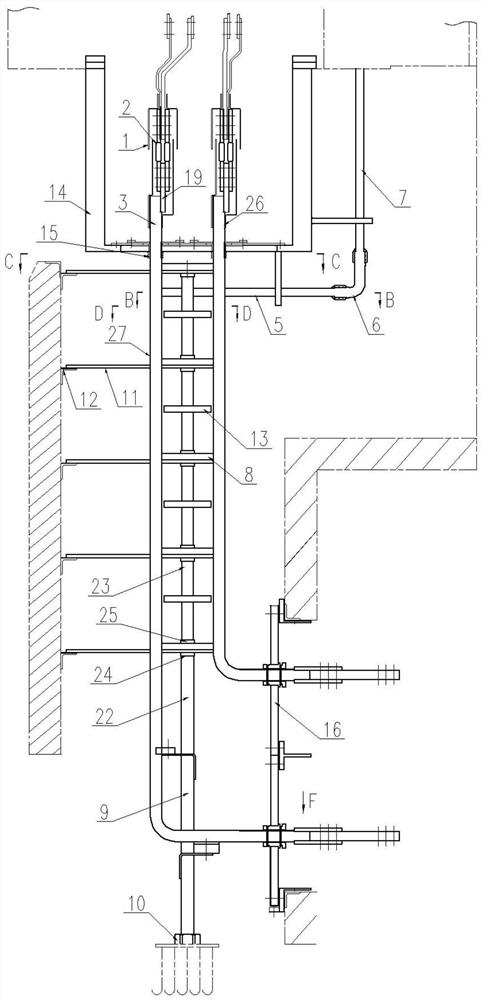

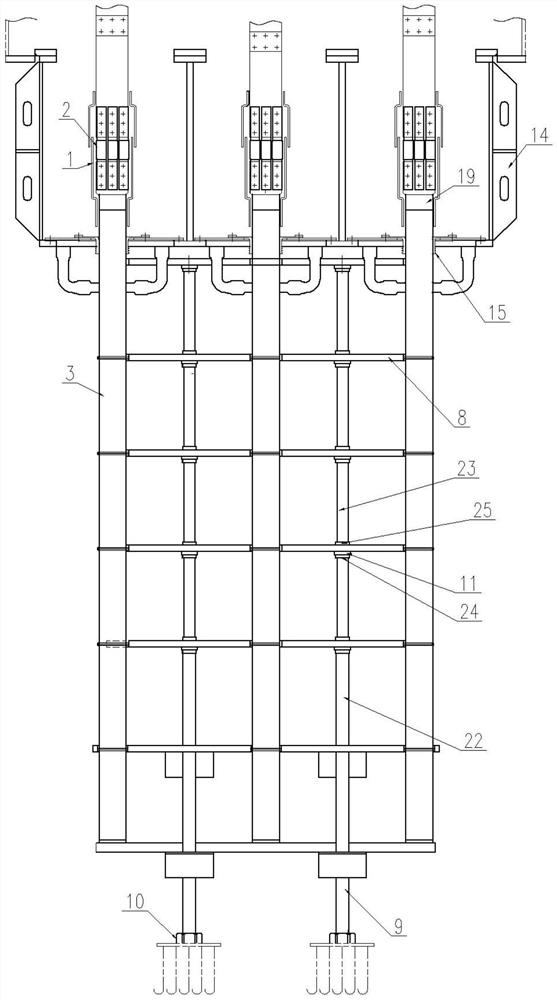

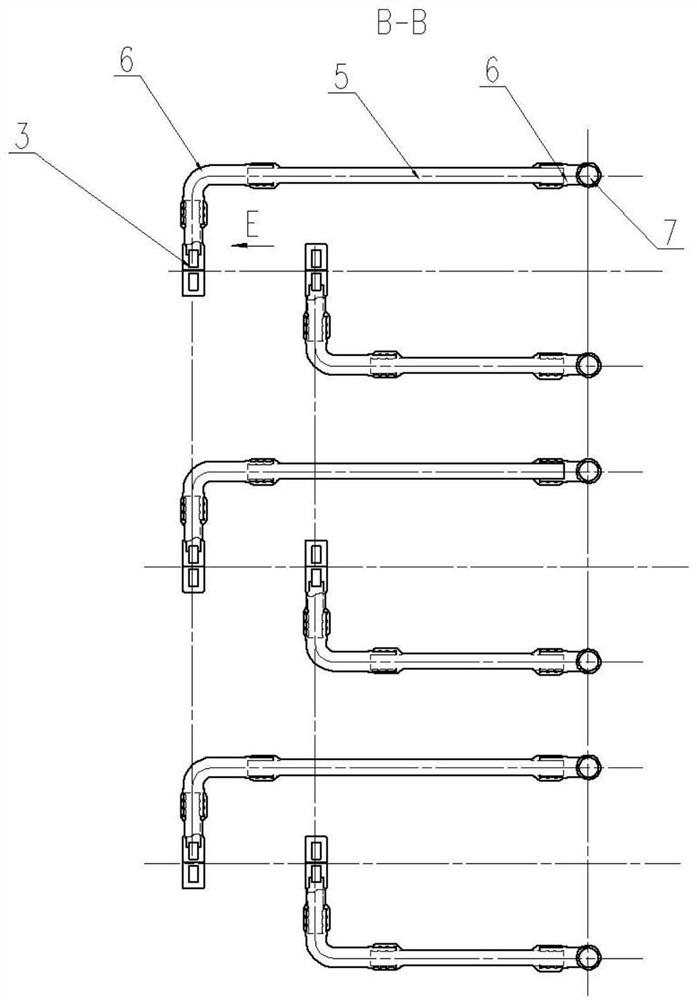

[0026] Such as figure 1 and Figure 9 As shown, the cooling air enters from the air inlet of the insulation box 1 at the lead end, flows through the flexible connection 2, and enters the copper bar 3 in parallel. The insulation box 1 is divided into upper and lower halves. Partially open the mask and leave a certain gap, which can ensure smooth air intake and prevent foreign matter such as dust from entering the internal air duct. The cross-section of the copper bar 3 is as follows: Figure 8 , which is in the shape of "day", and the outer wrapping insulation is 18. Such as Figure 5 As shown, a blocking plate 4 is placed in front of the horizontal air outlet pipe 5 to block one air path of the copper bar, and a hole is opened in the middle partition between the two air paths in front of the blocking plate 4, so that the two air inlets can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com