Glass, chemically tempered glass, and method for producing same

A technology of strengthening glass and manufacturing method, applied in the field of glass, can solve the problem of low CT limit of glass, and achieve the effects of high strength, large fracture toughness value, and not easy to devitrify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

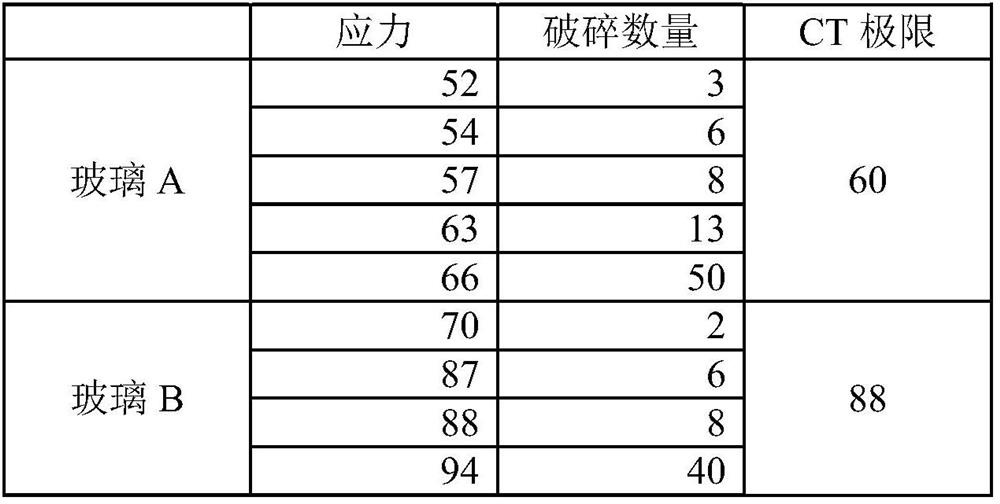

[0149] Hereinafter, the present invention will be described using examples, but the present invention is not limited thereto. G7 to G15 are examples of the glass of the present invention, and G1 to G6 are comparative examples. S4 to S6 are examples of the present chemically strengthened glass, and S1 to S3 are comparative examples. In addition, about each measurement result in a table|surface, the blank column shows that it was not measured.

[0150] (making of glass)

[0151] Glass raw materials were prepared so as to have the glass compositions described in Tables 3 to 4 in terms of mole percentages based on oxides, and were melted and polished to produce glass plates. G1 is the glass A mentioned above. Also, X in the table means Y 2 o 3 , La 2 o 3 , Nb 2 o 5 、 Ta 2 o 5 and WO 3 The total content of .

[0152] As the glass raw material, general glass raw materials such as oxides, hydroxides, and carbonates are appropriately selected so as to be weighed so as to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com