A 7055 aluminum alloy flat row and its production process and application

A production process and technology for aluminum alloys, applied in the field of aluminum alloys, can solve the problems of poor compression performance and large product weight, and achieve the effect of high fracture toughness value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

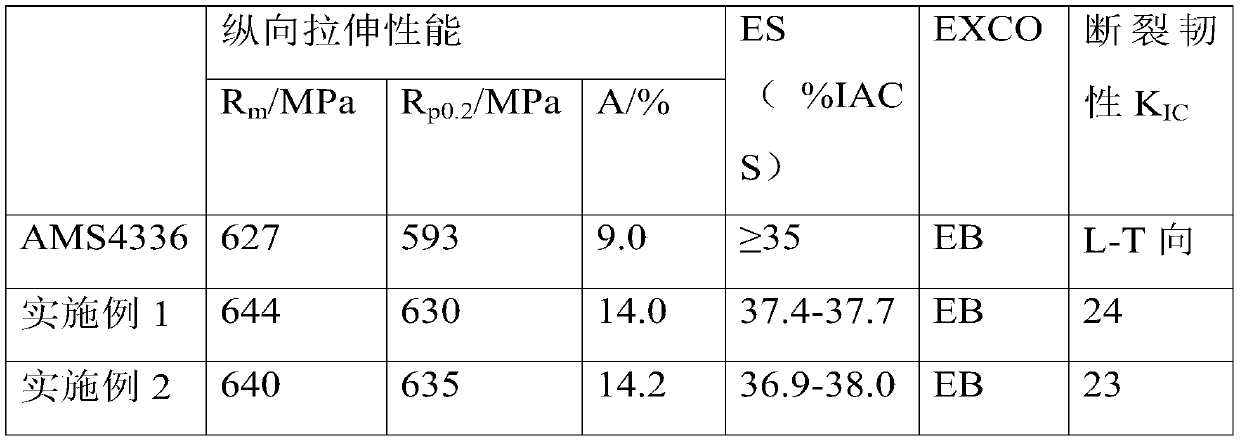

Embodiment 1

[0044] This embodiment provides a 7055-T76511 flat row, which is prepared by the following preparation method:

[0045] Prepare raw materials according to the weight fraction composition of alloy elements of 7055 aluminum alloy: Si: 0.02%, Fe: 0.04%, Cu: 2.12%, Mg: 2.03%, Mn: 0.004%, Cr: 0.006%, Zn: 7.98%, Ti: 0.04%, Zr: 0.1%, and the balance is Al. Pour pure electrolytic aluminum liquid into a pouring melting furnace, add other alloy element components, and then smelt to obtain an aluminum alloy melt with uniform composition. The alloy melt is cooled and cast into cast rods.

[0046] Put the cast rod into the homogenization furnace for two-stage homogenization treatment. The first-stage homogenization treatment is to keep warm at 460°C for 30 hours, and the second-stage homogenization treatment is to keep warm at 475°C for 8 hours; The heating rate during chemical treatment was 40°C / min.

[0047] Put the homogenized cast rod into the extrusion barrel of a 150MN extruder for...

Embodiment 2

[0053] This embodiment provides a 7055-T76511 flat row, which is prepared by the following preparation method:

[0054] Raw materials are prepared according to the weight fraction composition of alloy elements of 7055 aluminum alloy: Si: 0.04%, Fe: 0.05%, Cu: 2.22%, Mg: 2.1%, Mn: 0.03%, Cr: 0.01%, Zn: 8.02, Ti: 0.03 %, Zr: ≤0.05%, the balance is Al, pour the pure electrolytic aluminum liquid into the pouring melting furnace, add other alloy element components, and then smelt to obtain an aluminum alloy melt with uniform composition, and then pour the aluminum The alloy melt is cooled and cast into cast rods.

[0055] Put the cast rod into the homogenization furnace for two-stage homogenization treatment. The first-stage homogenization treatment is to keep warm at 455°C for 32h, and the second-stage homogenization treatment is to keep warm at 470°C for 8.5h. The temperature increase rate during the homogenization treatment was 38° C. / min.

[0056] Put the homogenized cast rod...

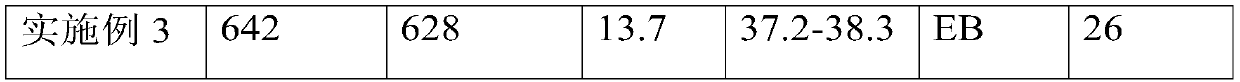

Embodiment 3

[0062] This embodiment provides a 7055-T76511 flat row, which is prepared by the following preparation method:

[0063] Raw materials are prepared according to the weight fraction composition of alloy elements of 7055 aluminum alloy: Si: 0.01%, Fe: 0.03%, Cu: 2.08%, Mg: 1.98%, Mn: 0.005%, Cr: 0.005%, Zn: 7.76%, Ti: 0.04%, Zr: 0.09%, and the balance is Al. Pour pure electrolytic aluminum liquid into a pouring melting furnace, add other alloy element components, and then smelt to obtain an aluminum alloy melt with uniform composition. The alloy melt is cooled and cast into cast rods.

[0064] Put the cast rod into the homogenization furnace for two-stage homogenization treatment. The first-stage homogenization treatment is to keep warm at 460°C for 30h, and the second-stage homogenization treatment is to keep warm at 470°C for 7.5h. The temperature increase rate during the homogenization treatment was 42° C. / min.

[0065] Put the homogenized cast rod into the extrusion barrel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com