Preparation process for integrated enhancing hardness and breaking toughness of omposite material with MoSi2 base by addiing multi-element

A composite material and fracture toughness technology, which is applied in the field of preparation of MoSi2-based composite materials, can solve problems such as increased cost and complicated process, and achieve the effect of increasing the value of fracture toughness, hardness and fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

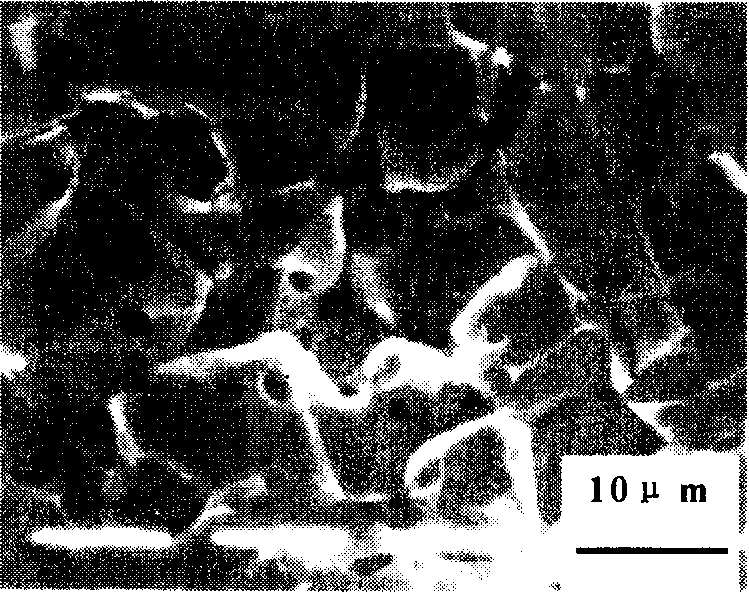

[0014] Example 1: Select 400 mesh Mo powder and Si powder and add 200 mesh 10mol.% W and 0.2wt.% La two element powders for mixing at the same time, and alloy them under the action of ball milling in a high-energy ball mill to make them in situ Formation of solid solution WSi 2 and the dispersed second phase particles La 2 o 3 , and then sieved to 200 meshes, press the synthesized composite material powder into shape, the pressure is 100Mpa, hold the pressure for 2 minutes; put the green compact into the sintering furnace and sinter at 1600°C under the hydrogen atmosphere, keep it warm for 2 hours, and cool down with the furnace to obtain Product, the product is silver gray solid.

Embodiment 2

[0015] Example 2: Select 200 mesh Mo powder and Si powder and add 400 mesh 15mol.% W and 0.5wt.% La two element powders to mix at the same time, use tungsten wire to ignite under vacuum in a high temperature self-propagating device, resulting in self The propagation reaction occurs, and the synthesized composite material powder is hot-pressed. The hot-pressing temperature is 1700°C, the holding time is 1 hour, and the applied pressure is 25Mpa. The product is silver gray solid.

Embodiment 3

[0016] Example 3: Select 300 mesh Mo powder and Si powder and add 300 mesh 20mol.% W and 2.0wt.% La two element powders to mix at the same time, use tungsten wire to ignite under vacuum in a high temperature self-propagating device, resulting in self Propagation reaction occurs, the synthetic composite material powder is compacted, the pressure is 500Mpa, and the pressure is kept for 1 minute; the compact is placed in a sintering furnace and sintered at 1800°C under a hydrogen atmosphere, kept for 1 hour, and cooled with the furnace to obtain the product. It is silver-gray solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com