Quality guarantee device with cleaning function

A technology of preservation and function, which is applied in the direction of mixers with rotating stirring devices, chemical instruments and methods, chemical/physical processes, etc., which can solve the problems of inconvenient cleaning of the inner wall of the cylinder of the preservation, and achieve the effect of quick and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

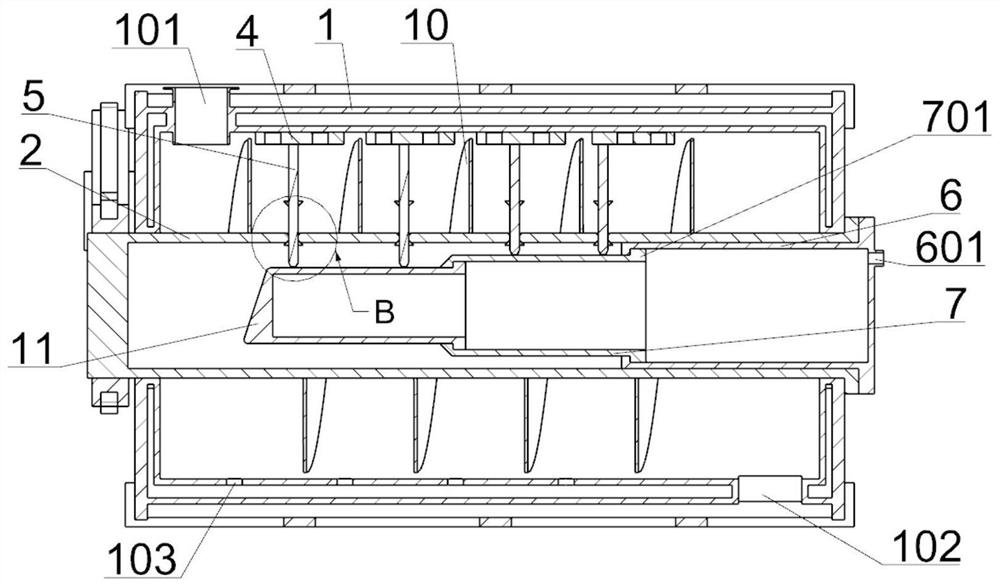

[0012] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

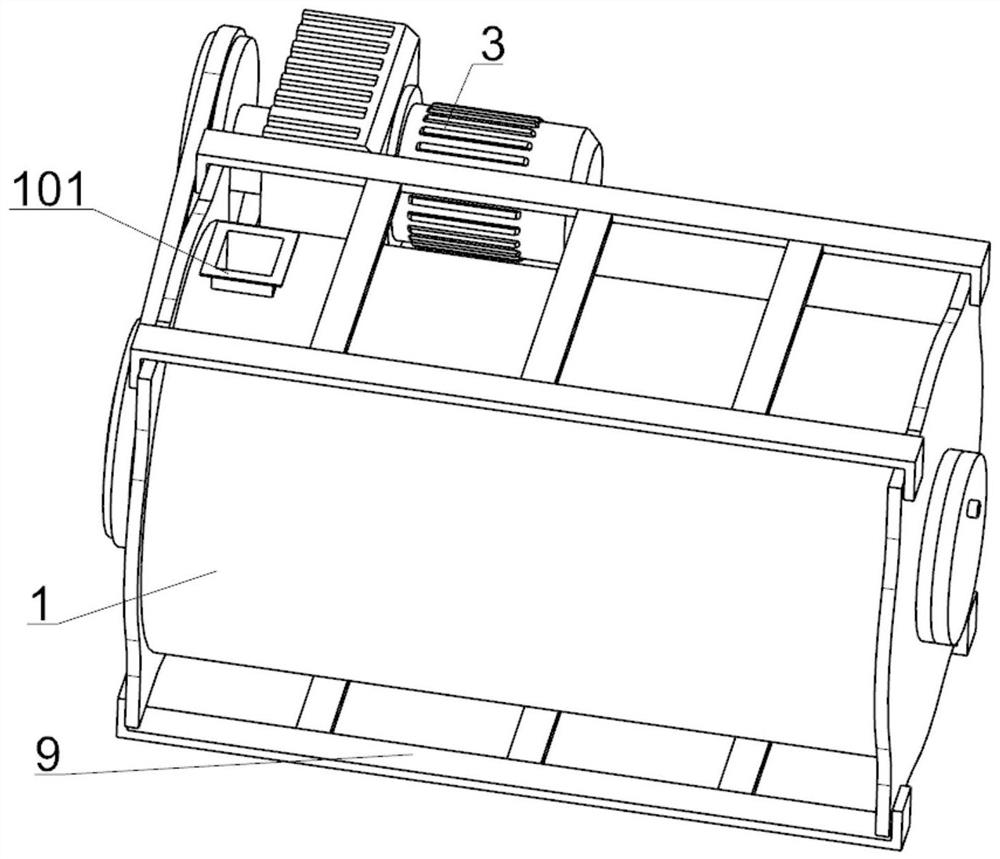

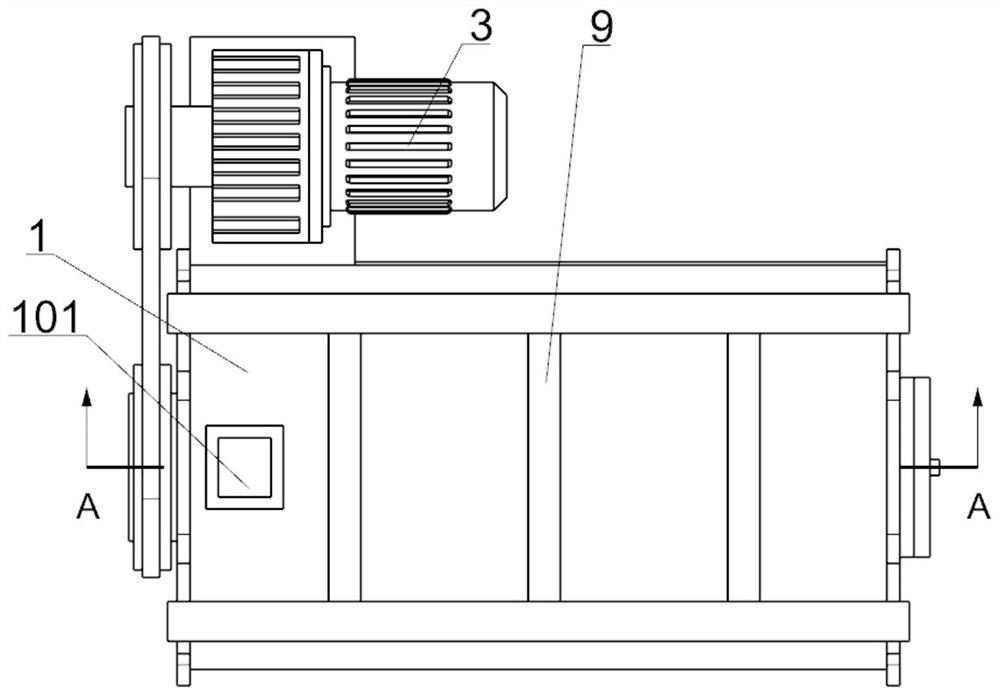

[0013] like Figure 1 to Figure 3 As shown, a preservation device with a cleaning function includes a cylinder body 1, a main shaft 2, a drive unit and a plurality of cleaning units, wherein the cylinder body 1 is supported by a conventional bracket 9 to facilitate movement and fixing, and the cylinder body 1 The top of one end is provided with a feed port 101 that communicates with the interior, and the bottom of the other end of the cylinder 1 is provided with a discharge port 102 that communicates with the outside world. The cylinder 1 is provided with an interlayer, and the interlayer and the inner cavity of the cylinder 1 pass through the steam port. 103 is connected to facilitate the injection of water vapor or other additives that need to be mixed with the feed into the inner cavity of the cylinder 1 during work; the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com