Cigarette pile film wrapping method

A technology for bar cigarettes and coating, which is applied in packaging, wrapping objects, packaging cigarettes, etc., can solve the problems of low efficiency and poor stability of cigarette stacks, and achieves good commercial application value, beautiful appearance, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

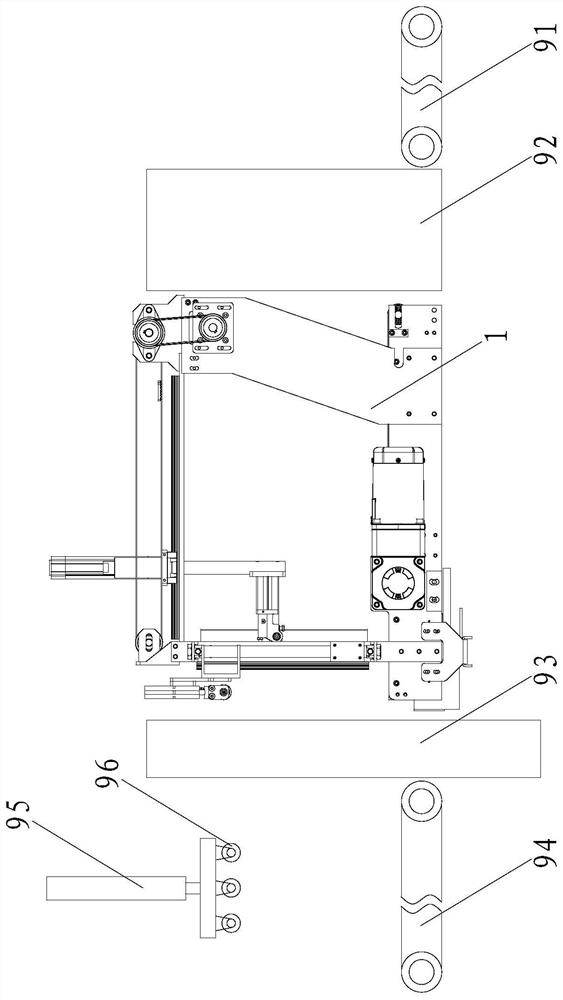

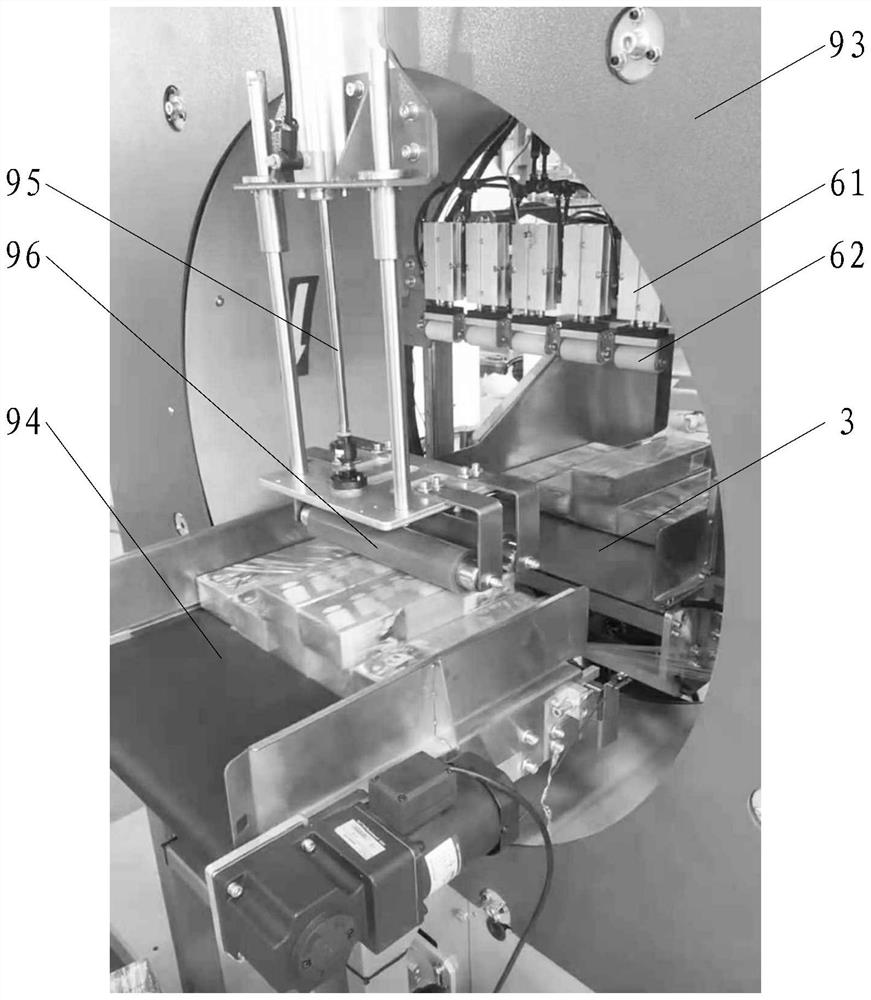

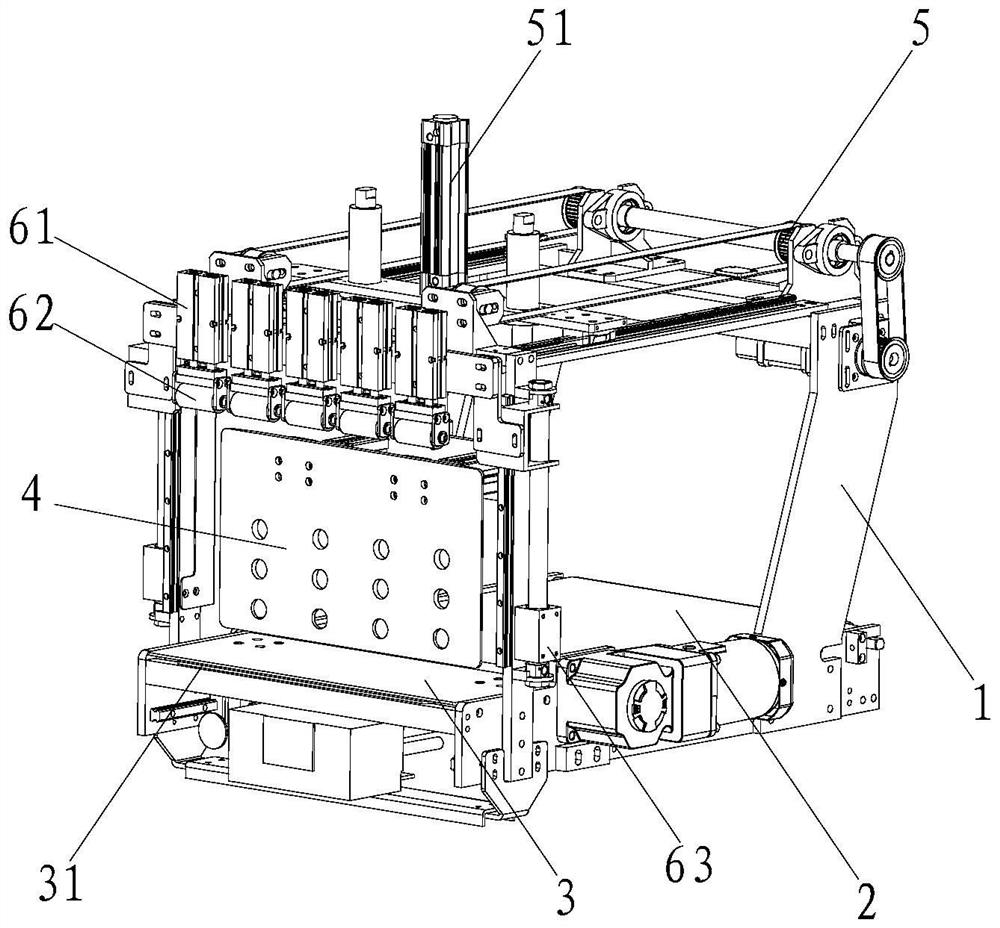

[0031] refer to figure 1 , figure 2 , the present embodiment provides a cigarette stick packaging machine, including a frame and a palletizing pile conveying mechanism 91, a film covering mechanism 92, a cigarette pile pushing mechanism, a wrapping wrapping mechanism 93, and an output conveyor belt 94 arranged according to the assembly line. The distance between the output conveying belt 94 and the cigarette pushing mechanism is greater than the width of the wrapping film surrounding the wrapping mechanism 93, and the wrapping mechanism 92 realizes the wrapping of a circle of the stack of cigarettes to form a first wrapping film. The surrounding coating mechanism realizes the coating of the other circumference of the cigarette stack to form a second film, and the first and second films are respectively distributed along the horizontal and vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com