Screw conveyor with drying function

A technology of screw conveyor and drying function, applied in the field of screw conveyor with drying function, can solve the problems of long screw conveyor, inability to change the direction of material movement, trouble, etc., to reduce costs, facilitate maintenance and warranty, reduce The effect of the cost of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

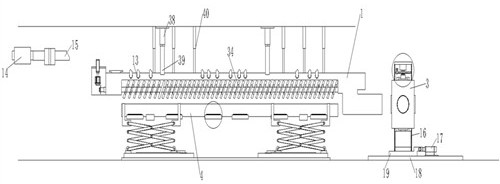

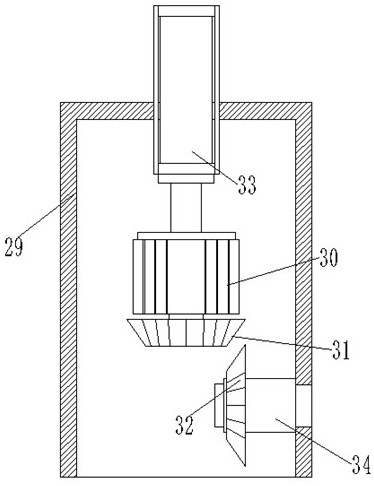

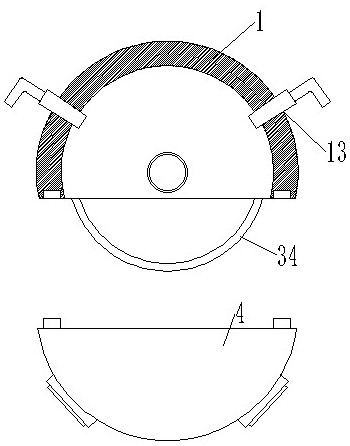

[0044] Embodiment: a screw conveyor with a drying function, including a hoisting structure, a conveying pipeline 1, a docking pipeline, and a docking box 3, the conveying pipeline 1 is arranged on the hoisting structure, and the conveying pipeline 1 is provided with a power system and a drying structure. The docking box 3 is provided with an automatic docking structure;

[0045] It should be noted that, in the above, when the material needs to be dried and heated through the conveying pipeline 1, the material inside the conveying pipeline 1 can be heated through the drying structure, and in the later maintenance and cleaning of the material inside the conveying pipeline 1 When the material remains, the conveying pipeline 1 can be opened by lifting the drying structure. When the material conveying direction needs to be changed, the position can be changed by the hoisting structure, and the pipeline can be connected by using the automatic docking structure. At the same time, due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com