Coating production filling device capable of facilitating metering

A filling device and coating technology, which is applied in the safety device of the filling device, packaging, liquid bottling, etc., can solve the problems of inaccurate placement, injection, and increased filling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

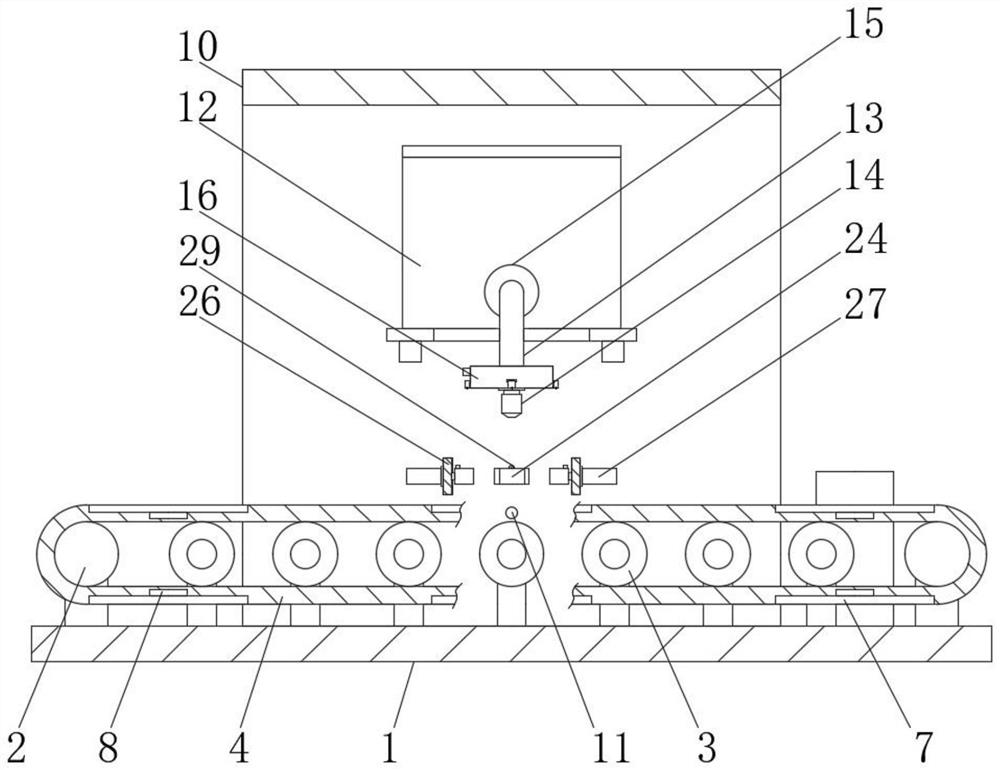

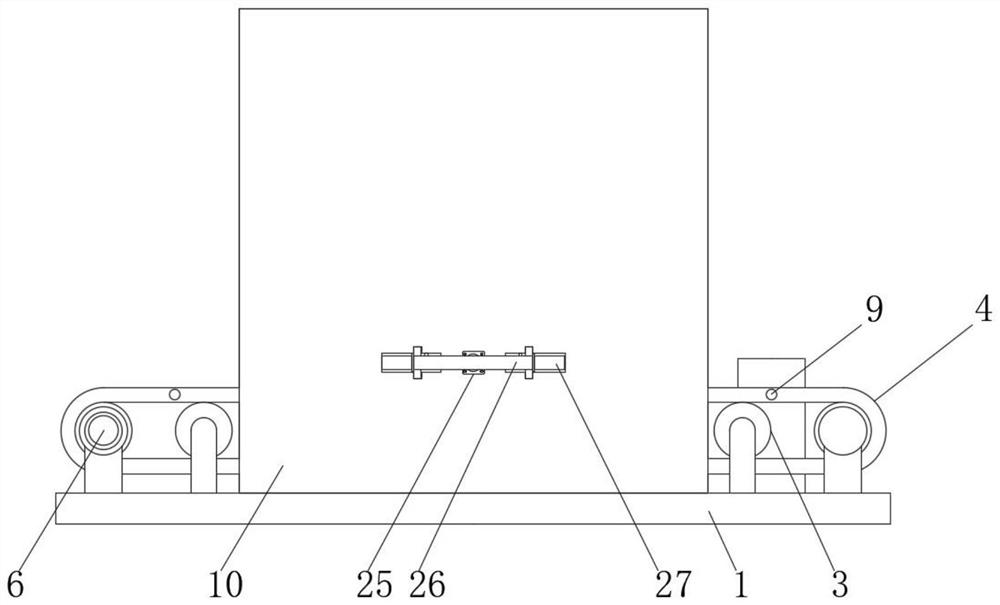

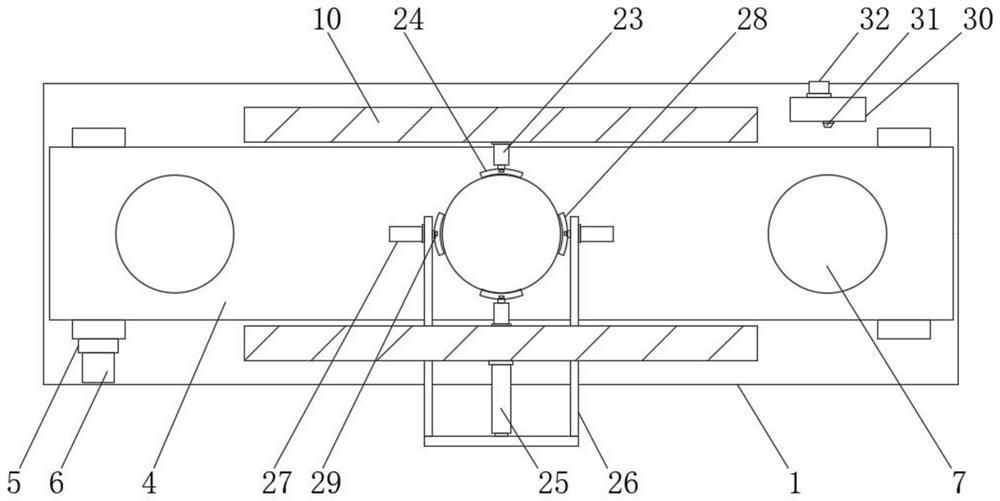

[0025] As shown in the drawings, the embodiment of the present invention provides a convenient metering paint production and filling device, including a base 1, a driving roller 2 is installed on the top side of the base 1, and a speed reducer 5 is installed on the outer wall of the driving roller 2 , the outer side of the reducer 5 is equipped with a first motor 6, and the top side of the base 1 is evenly equipped with a plurality of supporting rollers 3 at a position far away from the driving roller 2, and the plurality of supporting rollers 3 and the outer surface of the driving roller 2 are sleeved There is a transmission belt 4, and the outer surface of the transmission belt 4 is evenly provided with a plurality of positioning grooves 7, and the inner bottom sides of the plurality of positioning grooves 7 are all embedded with a weighing module 8, and the outer side of the transmission belt 4 corresponds to the positioning groove 7 The positions on the sides are all embedd...

Embodiment 2

[0032] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0033] Specifically, the top of the base 1 is fixedly connected with a side frame 30 near the side of the support frame 10, the outer wall of the side frame 30 is equipped with an alarm horn 32, and the inner wall of the side frame 30 is equipped with a second infrared emitter 31, Facilitate when the packing can that injects paint is moved to side frame 30 one side, the infrared receiver 9 outside this positioning slot 7 is aimed at the second infrared emitter 31, then driving roller 2 stops, and alarm horn 32 sounds, so that The lifting staff will collect the packaging jars in time.

[0034] Specifically, the second infrared emitter 31 is on the same horizontal line as the first infrared emitter 11 , so that the second infrared emitter 31 can be aligned with the infrared receiver 9 like the first infrared emitter 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com