Matching components for blowout preventers in drilling tools

A technology of supporting components and internal blowout prevention, which is applied in the parts of lighting devices, lighting devices, valve devices of wellbore/well, etc. It can solve problems such as tool damage and stable assembly, so as to reduce potential safety hazards and ensure effective installation. , The effect of improving the safety of well entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

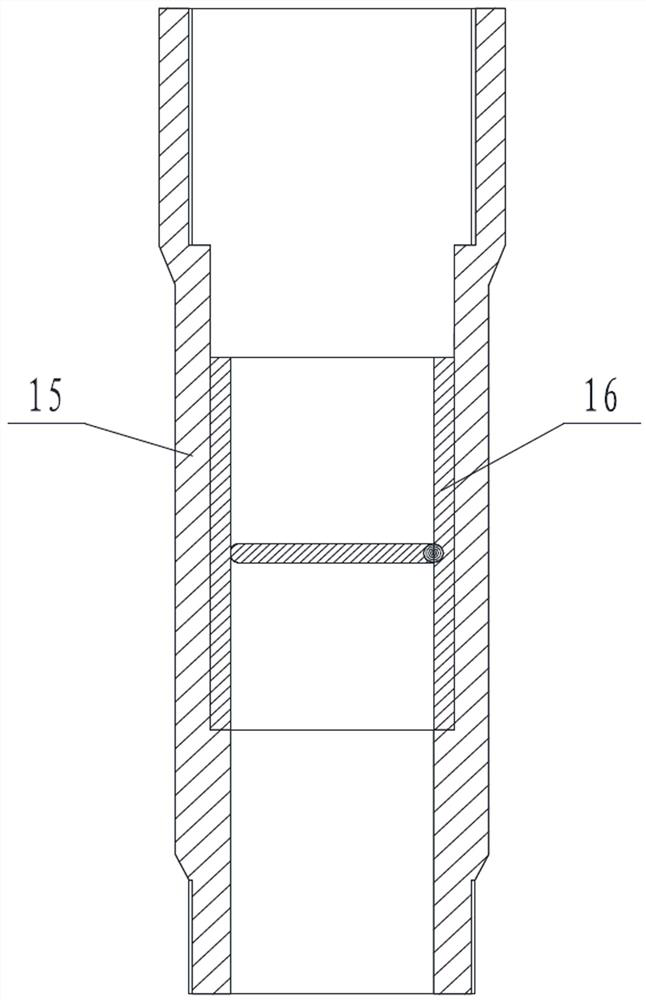

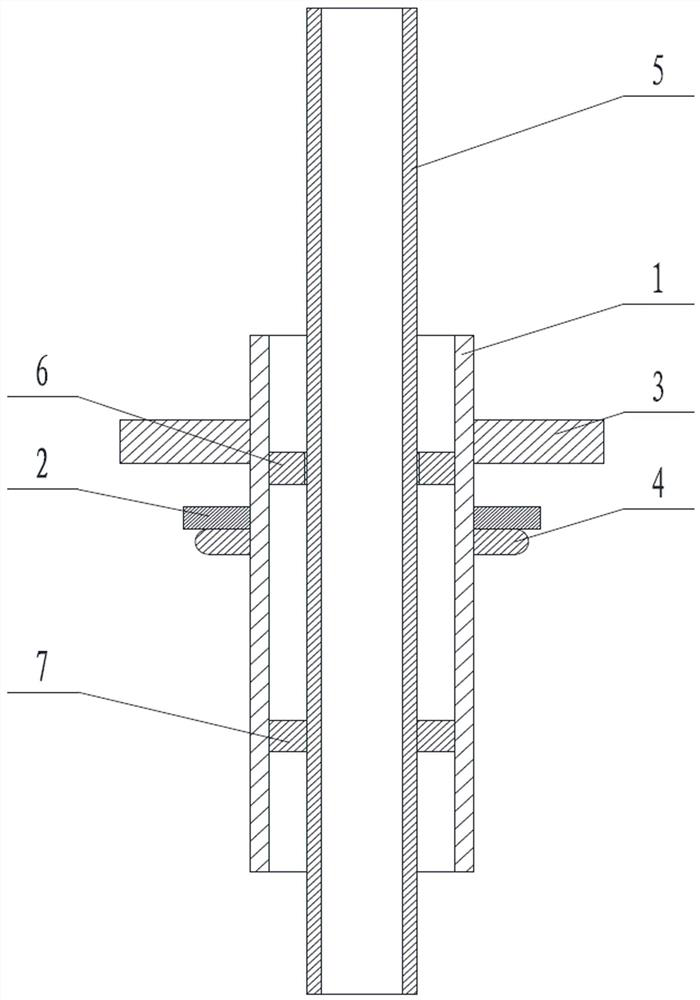

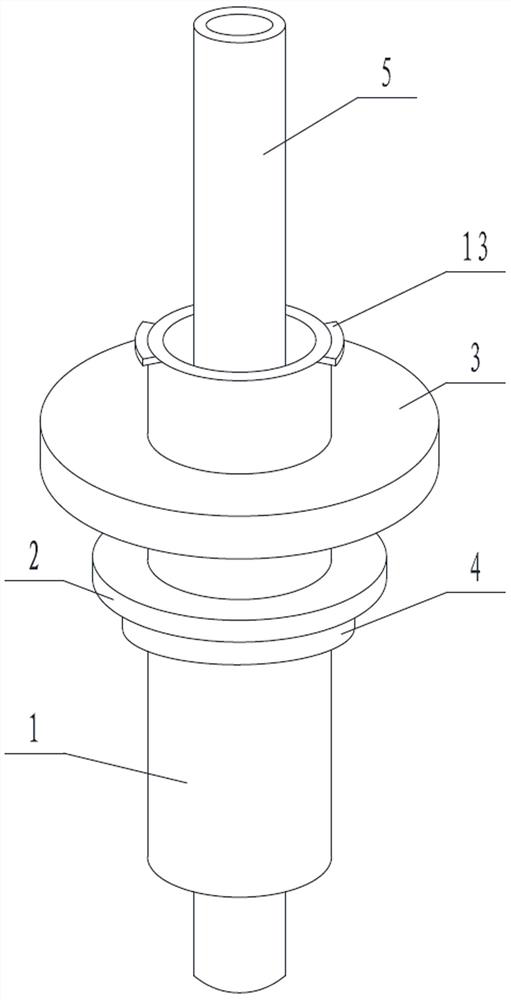

[0033] A supporting component for the inner blowout preventer of the drilling tool, its function is to assist when the inner blowout preventer is installed in the housing 15, such as Figure 2 to Figure 4 As shown, it includes an outer cylinder 1, a force-bearing member 2 fixedly sleeved on the outer wall of the outer cylinder 1, and a force-applying member 3 slidingly sleeved on the outer wall of the outer cylinder 1. The force-applying member 3 is located above the force-bearing member 2. A buffer layer 4 is provided at the bottom of the force member 2; the outer diameter of the outer cylinder 1 is the same as that of the matching inner blowout preventer; it also includes a middle cylinder 5 that runs through the outer cylinder 1, and the middle cylinder 5 and the outer cylinder 1 are coaxial, and the middle cylinder 5 can move axially in the outer cylinder 1.

[0034] Such as figure 2 As shown, the first centering device 6 and the second centering device 7 distributed up ...

Embodiment 2

[0039] The supporting assembly for the blowout prevention device in the drilling tool, on the basis of embodiment 1, also includes such as Figure 5 As shown in the base 8 , a cylindrical boss 801 is arranged on the top of the base 8 , and a first light source 802 is embedded on the top surface of the cylindrical boss 801 .

[0040] The state of base 8 when in use is as Figure 6 As shown, it is sufficient to cover the male buckle end at the bottom of the housing 15 on the outside of the boss 801 on the base.

[0041] Preferably, the outer diameter of the boss 801 shown is equal to the inner diameter of the male buckle end at the bottom of the housing 15 .

Embodiment 3

[0043] For the supporting assembly of blowout preventer in drilling tool, on the basis of embodiment 2, such as Figure 7 and Figure 8 As shown, it also includes an inner cylinder 9 that can move axially in the middle cylinder 5, and the length of the inner cylinder 9 is greater than the length of the middle cylinder 5; the bottom end of the inner cylinder 9 is provided with a first reflector 10, an inner cylinder 9. A second reflective mirror 11 is provided at the top; the first reflective mirror 10 is used to reflect the light coming from the radial direction of the inner tube 9 to the second reflective mirror 11 through the inner tube 9 . The outer diameter of the inner cylinder 9 is equal to the inner diameter of the middle cylinder 5, and the inner cylinder 9 and the middle cylinder 5 are slidingly fitted.

[0044] The first reflective mirror 10 is fixedly connected to one side of the bottom end of the inner cylinder 9, and the first reflective mirror 10 is inclined tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com