Yielding hollow steel tube concrete support and construction method

A technology of steel tube concrete and self-compacting concrete, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of self-heaviness, excessive stiffness of components, and influence on the strength of supports, so as to reduce self-weight, enhance bending strength, The effect of improving the yielding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

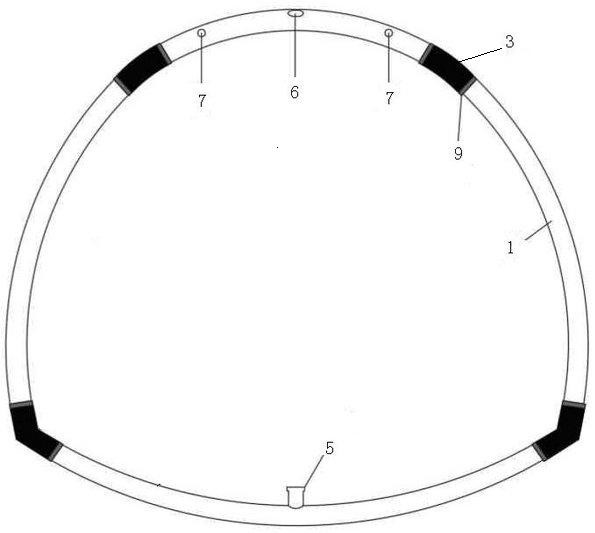

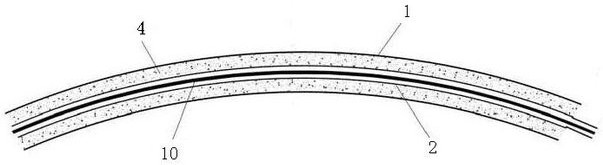

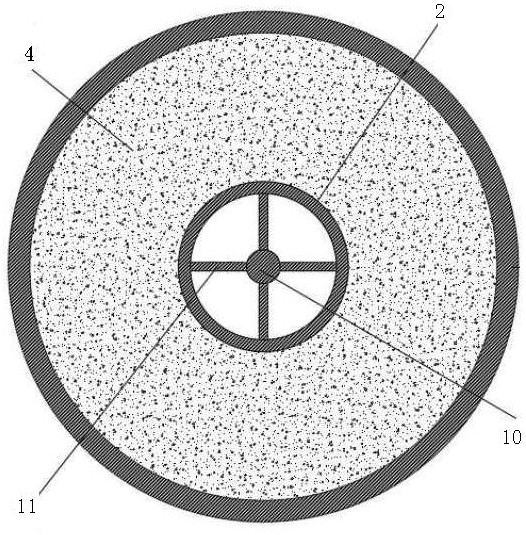

[0028] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 A pressure-free hollow concrete-filled steel tube support, comprising an upper arc-shaped pipe member and a lower arc-shaped pipe member, the outer layer of the upper arc-shaped pipe member and the lower arc-shaped pipe member is an outer steel pipe 1, and an inner Steel pipe 2; positioning rods 8 are spirally arranged at uniform intervals in the axial direction between the inner wall of the outer steel pipe and the outer surface of the inner steel pipe;

[0029] Concrete 4 is poured between the outer surface of the inner steel pipe 2 and the inner surface of the outer steel pipe 1;

[0030] A shaft tube 10 is also arranged at the inner center of the inner steel pipe;

[0031] A support plate 11 is also provided between the surface of the shaft tube and the inner surface of the inner steel pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com