Cooling structure for enhancing heat dissipation of packaging body

A technology of cooling structure and packaging body, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of no heat dissipation structure, etc., and achieve the effect of improving heat dissipation and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

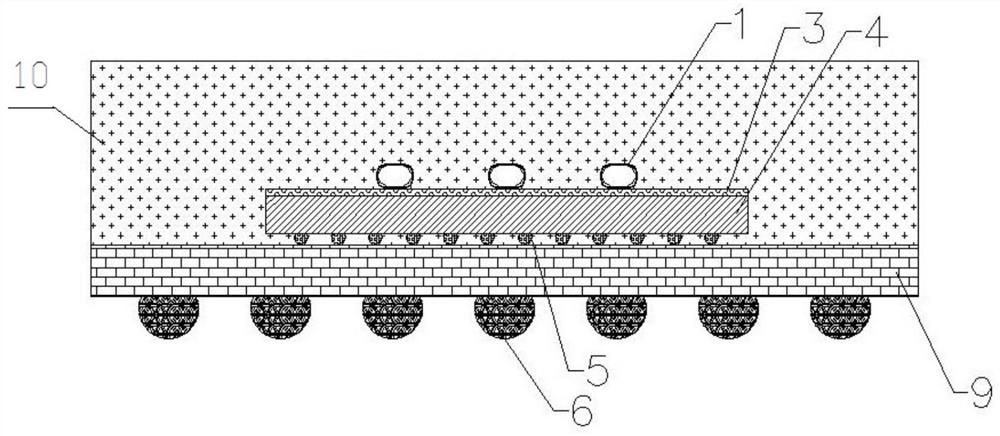

[0034] see figure 1 , image 3 and Figure 5 A metal post 5 is arranged between the lower end surface of the chip 4 and the carrier 9, and the metal post 5 can transmit electrical signals between the chip 4 and the carrier 9, so that the effective area of the upper surface of the chip 4 is increased. The chip 4 is the main part of heat dissipation. When the upper surface area of the chip 4 is large, the cavity pipe 1 is preferentially arranged on the upper surface of the chip 4 , and the cavity pipe 1 is attached to the upper surface of the chip 1 through the medium 3 . In order to increase the cooling area, the cavity pipe 1 is arranged in a U-shaped detour on the upper surface of the chip 4. The specific number of detours is determined according to the actual surface area of the chip. The medium 3 is an adhesive with high thermal conductivity.

[0035] see image 3 , The chip 4 is provided with a cavity pipe 1, the inlet and outlet of which are respectively arranged...

Embodiment 2

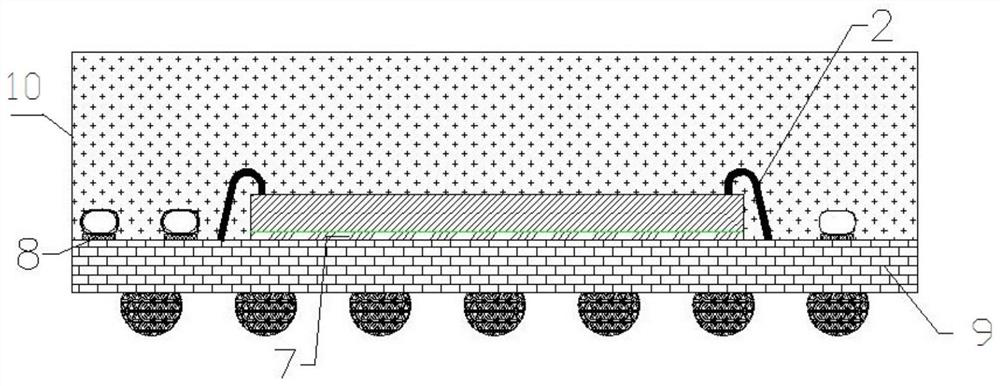

[0037] see figure 2 , Figure 4 and Figure 6 The chip 4 is pasted on the carrier board 9 through the first glue 7 , and the upper surface of the chip 4 is connected to the carrier board 9 through several bonding wires 2 for electrical signals. In this embodiment, the upper surface area of the chip 4 is not large, so that the cavity pipeline 11 is not suitable for being arranged on the upper surface of the chip 4, the cavity pipeline 11 is arranged around the chip 4, and the cavity pipeline 11 is arranged in a circle around the chip 4, The cavity pipe 11 is pasted on the upper surface of the carrier plate 9 through the second glue 8, and the first glue 7 and the second glue 8 are both high thermal conductivity adhesive glue.

[0038] see Figure 6 , the chip 4 is rectangular, and the cavity pipeline 11 is arranged around the four sides of the chip 4, and the cavity pipeline 11 on each side of the chip 4 can be straight, wavy or U-shaped, and is set according to the free ...

Embodiment 3

[0041] When the chip 4 and the carrier board 9 are provided with cavity pipes 11 at the same time, the cavity pipes 11 on the chip 4 and the carrier board 9 are two separate cavity pipes 11 .

[0042] The cavity pipeline 11 on the chip 4 is connected to the chip 4 through the medium 3 , and the cavity pipeline 11 can be arranged on the chip 4 in a detour.

[0043] The cavity pipe 11 on the carrier plate 9 is connected to the carrier plate 9 through the second glue 8 , and the cavity pipe 11 is arranged around the chip 4 .

[0044] The inlet and outlet of the cavity pipeline 11 on the chip 4 are higher than the inlet and outlet of the cavity pipeline 11 on the carrier plate 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com