Packaging method of LED device with matte surface

A technology of LED devices and packaging methods, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of material and process parameter limitations, and achieve a stable matte effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

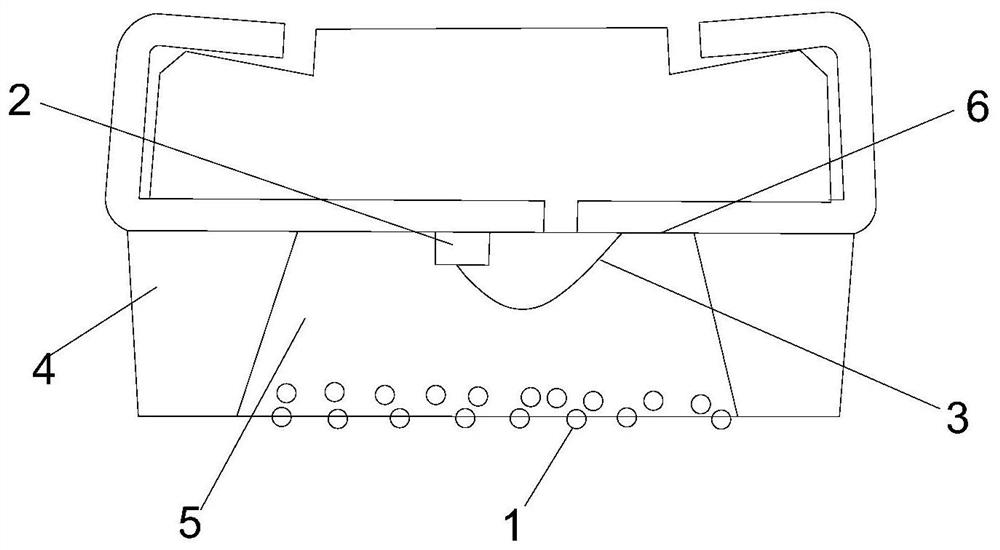

[0024] This embodiment provides a matte-surfaced LED lamp bead, which includes the following parts: LED bracket 4, LED light-emitting chip 2, wire 3 connecting LED light-emitting chip 2 and LED bracket 4, and colloid 5 covering the inside of the bowl , there are multiple silica micropowder particles 1 inside and on the surface of the colloid. In other embodiments, it can also be an LED flip-chip, so that there is no wire 3 .

[0025] In this implementation, silica powder 1 can be a solid spherical or irregular shape, deposited on the surface of the colloid in the figure, and dispersed in the interior of the colloid, its D 50 5-20μm, density 2-2.65kg / L. The colloidal surface has a surface roughness of 1-20 μm due to the action of silica micropowder.

[0026] The matte surface LED lamp bead of this embodiment, its encapsulation method comprises the following several steps:

[0027] (1) Assembling: bonding the LED light-emitting chip 2 to the support pad 6 with glue, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com