Membrane electrode structure and fuel cell

A membrane electrode structure and membrane structure technology, which are applied in fuel cells, solid electrolyte fuel cells, circuits, etc., can solve the problems of easy damage to the membrane electrode frame structure, and achieve the effect of saving materials, reducing costs, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Incidentally, in the case of no conflict, the embodiments of the present invention and the embodiment described features may be combined with each other.

[0029] Below with reference to drawings and embodiments of the present invention will be described in detail.

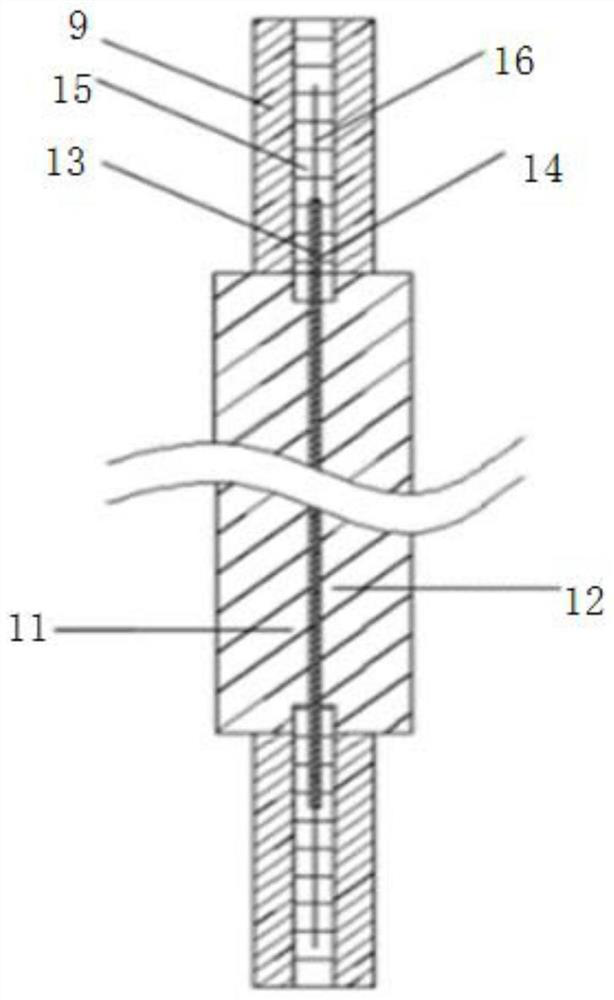

[0030] The present invention provides a membrane electrode structure, wherein said structure comprises a membrane electrode 8 and a peripheral edge of said clamp body 8 of the membrane structure of the film structure body 1, the rim portion of the frame portion holding the main body 1 comprises a direct tensile strength of the inner peripheral edge of the frame plate 8 of the outer membrane structure and a frame plate 15 holding plate 15 of the inner frame 9, the inner frame panel 15 is made larger than the material of the outer frame plate 9 tensile strength.

[0031] The membrane electrode for a fuel cell, which may be disposed between the cathode and the anode, both to allow for proton exchange. Wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com