Winding slot hole processing die set during motor stator core forming process

A molding process, motor stator technology, applied in the field of motor iron core manufacturing, can solve the problems of low production efficiency, low production cost, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

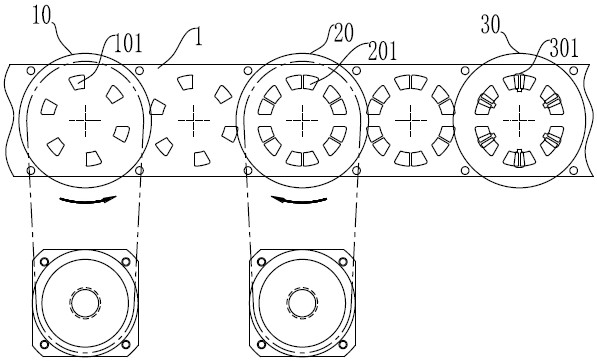

[0022] Example 1: The winding slot processing die set in the process of forming the stator core of the motor, the structure is as follows figure 1 and figure 2 As shown, it includes punching a slot die 10, punching b slot die 20 and punching c slot die 30 arranged in sequence on the strip traveling direction, and punching a slot die 10 includes several punches evenly arranged along the circumference. A slot hole punch 101, punch b slot hole die 20 includes some punch b slot hole punches 201 evenly arranged along the circumference; Slot hole punch 101 and several b slot hole punches 201 successively punch the same area on the strip, and obtain a number of a slots and a number of b slots, a number of a slots and a number of b slots uniformly arranged along the same circumference on the strip The holes one by one are distributed axially symmetrically and the symmetry axes of each pair of slots a and b slots pass through the center of the circle in which they are arranged; by ro...

Embodiment 2

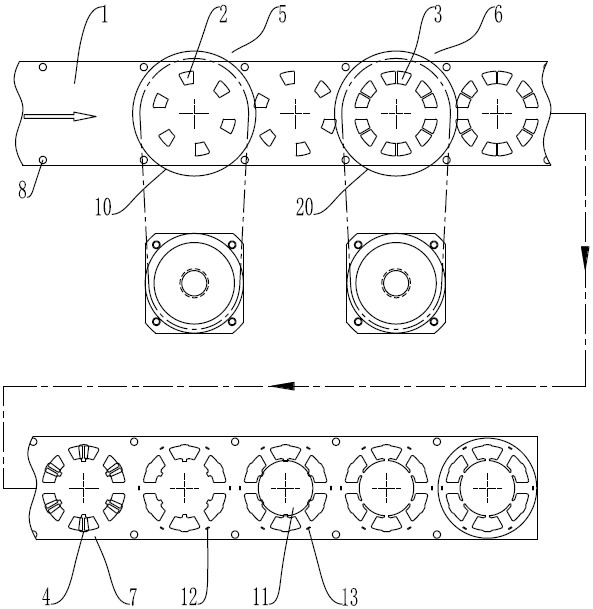

[0032] Embodiment 2: the present invention is the most important link in the manufacture of multi-group step winding slot motor stator cores, that is, it is finally used to manufacture structures such as Figure 4 The stator core shown, Figure 5 for Figure 4 Sectional view of the internal structure along the M-M direction.

[0033] It can be seen from the above two figures that the stator core manufactured in this embodiment is composed of 15 stator core monoliths stacked together, and the number of winding slots is 6. Among the 15 stator core monoliths, there are There are three stator core monoliths with different winding slot widths. The stator core monolithic body with the narrowest winding slot width is marked as O. There are 7 pieces, located in the middle of the entire stator core, and the winding slot width is the largest. The second narrowest stator core monolith is labeled P, and there are 4 pieces, two of which are located on the outer side of the stator core mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com