Ethylene-(vinyl alcohol) copolymer and method for producing same

A vinyl alcohol copolymer and copolymer technology, which is applied in the field of resin compositions and molded bodies, can solve the problems of complex melt viscosity change behavior over time, the problem of molded body performance, and the variation of molded body thickness distribution, and achieves stable melt molding process. Chemical resistance, excellent coloring resistance, and excellent viscosity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Hereinafter, although an Example etc. demonstrate this invention concretely, this invention is not limited to these Examples etc. at all. In addition, each analysis and evaluation in this Example etc. were performed by the following method.

[0101] (1) Ethylene unit content and saponification degree of EVOH

[0102] In deuterated dimethyl sulfoxide (DMSO-d) containing tetramethylsilane (TMS) as internal standard substance and trifluoroacetic acid (TFA) as additive 6 ) by dissolving the dry pellets obtained in each example and comparative example, using a 500MHz 1 H-NMR (manufactured by JEOL Ltd.: "GX-500") was measured at 80°C, and the ethylene unit content and saponification degree were determined from the peak intensity ratios of ethylene units, vinyl alcohol units, and vinyl ester units.

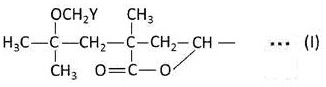

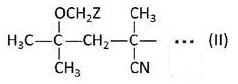

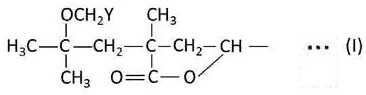

[0103] (2) Content of structure (I) and structure (II)

[0104] In DMSO-d containing TMS as internal standard substance 6 Dissolve the dry pellets obtained by each of the Exam...

Synthetic example 1

[0122] Using a pressurized reaction tank with a capacity of 250 L, polymerization was carried out under the following raw materials and conditions to obtain an ethylene-vinyl acetate copolymer.

[0123] ・Vinyl acetate: 83.0 kg

[0124] ・Methanol: 26.6kg

[0125] ・Polymerization initiator: 2,2'-azobis(4-methoxy-2,4-dimethylvaleronitrile) (2.5g / L methanol solution) initial supply volume: 362mL, continuous supply volume: 1120mL / hr

[0126] ・Polymerization temperature: 60℃

[0127] ・Ethylene pressure in the polymerization tank: 3.6MPa.

[0128] When the polymerization rate of vinyl acetate reached about 40%, sorbic acid was added, and the polymerization was stopped by cooling. Next, the reaction tank is opened to the atmospheric pressure, and after removing ethylene from the reaction system, the reaction solution is supplied to the recovery tower, and methanol vapor is introduced from the lower part of the tower, thereby removing unreacted vinyl acetate from the top of the to...

Synthetic example 2

[0130] A methanol solution of an ethylene-vinyl acetate copolymer having an ethylene unit content of 24 mol % was obtained in the same manner as in Synthesis Example 1 except that the polymerization conditions were changed as follows.

[0131] ・Vinyl acetate: 102.0 kg

[0132] ・Methanol: 17.7kg

[0133] ・Polymerization initiator: 2,2'-azobis(4-methoxy-2,4-dimethylvaleronitrile) (2.5g / L methanol solution) initial supply volume: 280mL, continuous supply volume: 850mL / hr

[0134] ・Ethylene pressure in the polymerization tank: 2.9MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com