Snail shell and meat separation equipment

A technology for separating equipment and screw shells, which is applied in the processing of crustaceans, slaughtering, shrimp/lobster processing, etc. It can solve the problems of mixed snail meat and snail shells, a lot of manpower, and difficulty in separating and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

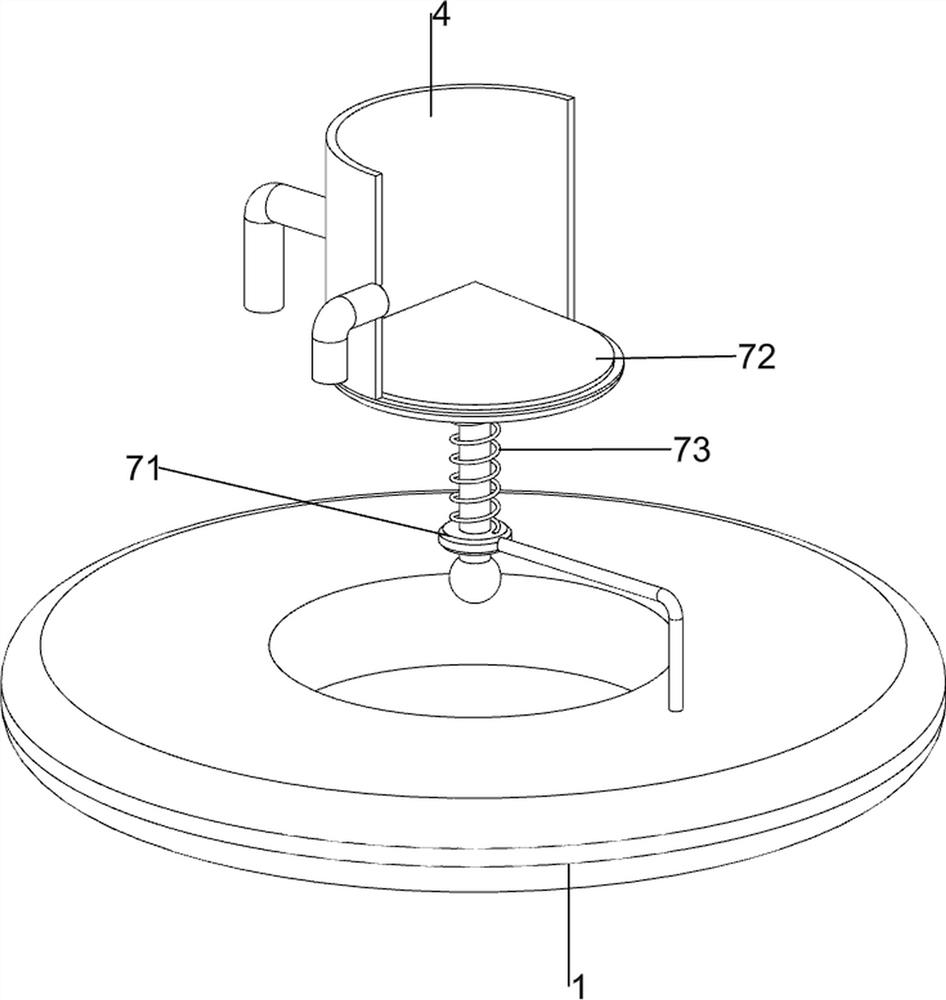

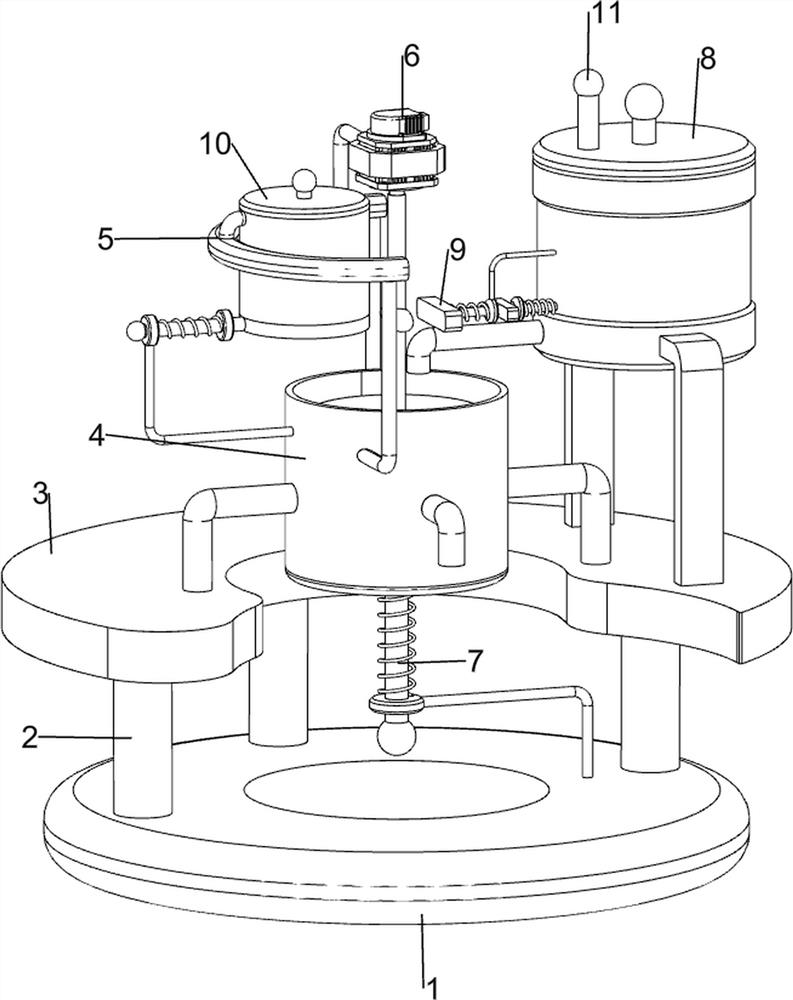

[0029] A kind of screw shell meat separation equipment, such as Figure 1-4 As shown, it includes a first support plate 1, a first support rod 2, a second support plate 3, a grinding tank 4, a support frame 5, a grinding mechanism 6, a discharge mechanism 7 and a water injection mechanism 8. The first support plate 1 First support rods 2 are arranged on the upper, left, right and rear sides, second support plates 3 are arranged between the tops of the three first support rods 2, and grinding tanks 4 are arranged between the centers of the second support plates 3, and the front and rear of the grinding tanks 4 A support frame 5 is provided between the upper left of the wall, a grinding mechanism 6 is provided between the rear of the support frame 5 and the grinding tank 4, and a discharge mechanism is provided between the bottom of the grinding tank 4 and the upper right side of the first support plate 1 7. A water injection mechanism 8 is provided on the right side of the top ...

Embodiment 2

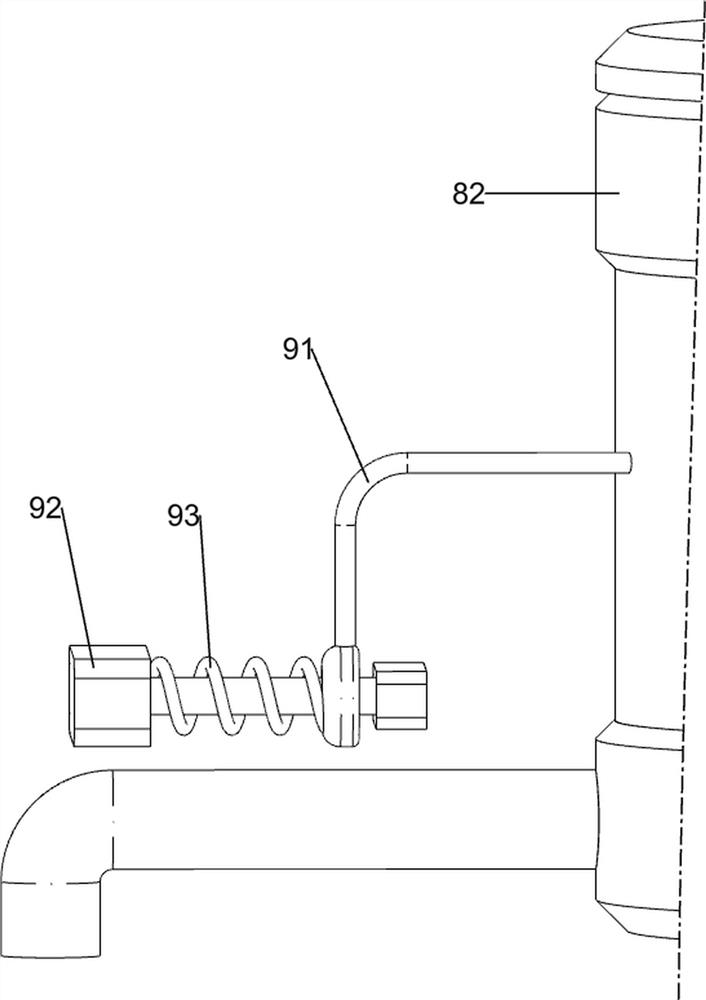

[0038] On the basis of Example 1, such as Figure 5-7As shown, an auxiliary mechanism 9 is also included, and the auxiliary mechanism 9 includes a fifth support rod 91, a squeezer 92 and a third spring 93, and the middle part of the left side wall of the water tank 82 parallel to the button 83 is provided with a fifth support rod 91 , the lower part of the fifth support rod 91 is slidingly provided with an extruder 92, the extruder 92 is in contact with the button 83, the third spring 93 is wound on the extruder 92, and the left and right ends of the third spring 93 are connected with the extruder 92 respectively. It is connected with the fifth support rod 91.

[0039] After the motor 62 is started, the output shaft of the motor 62 drives the cam 64 to rotate. When the cam 64 rotates and contacts the extruder 92, it drives the extruder 92 to move to the right, thereby driving the button 83 to move to the right, so that the third spring 93 is compressed, When the cam 64 rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com